Boric Acid Premix Silica Ramming Mass

5,000 Per Ton

1 Ton (MOQ)

Premix Ramming Mass

7 Per Kilogram

1000 Kilogram (MOQ)

Best Deals from Ramming Mass

Silica Ramming Mass

1 - 2 Per Kilogram

10 Ton (MOQ)

Premix Ramming Mass

9 Per Kilogram

Ramming Mass Powder

20 - 50 Per Kilogram

1 Metric Ton (MOQ)

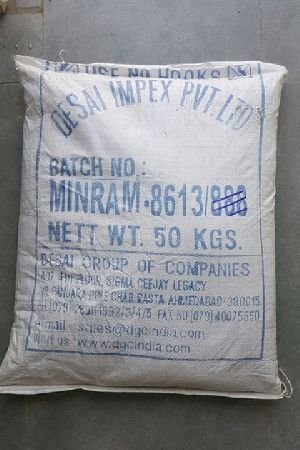

MIN RAM

Get Price Quote

This refractory mix is high alumina mix where in predominant aggregate component of alumina imparts a strong skeleton aggregate structure of superior uniform heat stability. The refractory mix is characterized by an ability to withstand corrosive-erosive attack of molten metal's and their acids, semi basic and basic slags during repeated exposure thereto, together with excellent volume stability, superior structure heat stability, low apparent porosity, a high contact angle with molten steel and strong abrasion resistance matrix.

Ramming Mass

Get Price Quote

We are the manufacturers and supplier of this products.

Acidic Ramming Mass

4,000 Per Metric Ton

The raw material chosen is a high grade quartzite and it has the folloeing advantages uniform hardness, high degree of refractoriness, good salg resistance. Specification : sio2-98 99.5% min, al2o3- traces, iron-nil sintering porosity-1200 degreec, compression strength- 350kgm3, bulk density- 2.0 to2.2 m.tm3 physical grading analysis : coarse - 35%, medum - 33%, fines - 32%. We provide after sale service also.

MIN RAM

Get Price Quote

This refractory mix is high alumina mix where in predominant aggregate component of alumina imparts a strong skeleton aggregate structure of superior uniform heat stability. The refractory mix is characterized by an ability to withstand corrosive-erosive attack of molten metal's and their acids, semi basic and basic slags during repeated exposure thereto, together with excellent volume stability, superior structure heat stability, low apparent porosity, a high contact angle with molten steel and strong abrasion resistance matrix.

Quartz Ramming Mass

Get Price Quote

Being a prestigious organization with plenty of positive records, we, as a Manufacturer are instrumental in providing the best Quartz Ramming Mass. It boasts features such as perfect fabrication, extended life and free from defects. Our audit team works hard to keep the quality in synchronization with industrial quality standards. Our esteemed customers can lay their hands on this wonderful quality at nominal rates.

Acidic Ramming Mass

Get Price Quote

Silica ramming mass, also known as acidic ramming mass, plays a crucial role in induction furnaces during melting of steel. This substance is used to line induction furnaces and its quality decides smooth working and more efficient output from the furnace. Ramming mass has a very important quality of withstanding of easily absorbing thermal shocks. It also does not develop cracks because of frequent power cuts during the operation of the induction furnace. Galaxy Enterprise makes very high quality silica ramming mass containing very dense silica quartz. This is why it a very respected name among silica ramming mass products from Indian industries. Galaxy Enterprise has the technical know how and a huge manufacturing plant in Gujarat. Experienced professionals having in depth knowledge of refractory materials mix different grain sizes of silica in just the right proportions to make ramming mass suitable for induction furnaces of various sizes. We make premix ramming mass containing boric acid as well as preheated ramming mass. Our ramming mass gives a great performance when it is used to line an induction furnace as it reduces cost of operations. This is why Galaxy remains the most popular silica ramming mass products manufacturers and exporters from India.

Steel Shots

64 - 80 Per

1 Metric Ton (MOQ)

Dear Sir/Mam Greetings from "Gemini Multi-trade Company''We introduce ourselves as one of the prominent suppliers of Abrasive Metal Like Steel shots ,Steel grits , Cut wire , Copper slag ,Iron Shots & etc.... in India.Please find the attached file in our product catalogue for your reference.We operate our office and warehouse from Ahmadabad , Gujarat. IndiaThe materials we propose to supply are atomized in the inert atmosphere of nitrogen which helps to produce defect free with superior abrasive quality. Looking forward to hearing from you . Thanks & Regards Yatharth Kumar (CEO) Gemini Multi-trade Company.4, Gopinath industrial park 2 Bakrol Bujrang, Ta. Daskroi, Ahmadabad India 382433 https://geminimultitradecompany.com/ Contact : +91 9406895554 / +91 9104581328

LADRAM

Get Price Quote

Fosterite based ramming mass for making laddles of foundry. Diluted sodium silicate to be used as binder before pre-heating. Method to use: After mixing 4-5% of diluted sodium silicate, good compact ramming is required to be done, talking special care of the impact area which is the bottom. After completing the ramming process slow pre-heating is requied to be done for 3-5 hours (depending on the capacity of the laddle). There after laddle is to be kept in red hot condition for one hour.

Lining Machine Neutral Ramming Mass

Get Price Quote

Lining Compactness Increased Lining Life, Reduced No. of Sintering and Increased in Output Liquid Metal Uniform Strength throughout Furnace Crucible Reduce Man Power Reduce Lining Time

Silica Ramming Mass

Get Price Quote

We supply snowwhite grade and super-snowwhite grade silica based ramming mass for various furnace capacities. Our ramming mass gives consistently excellent performance. We also offer premixed ramming mass (with boric acid)

Ramming Mass

Get Price Quote

1 FCL (MOQ)

Products : Ramming Mass Silica Cupola Ramming Mass Natural Ramming mass Acidic Ramming Mass Basic Ramming Mass(Magnesite MgO Base) Note : The information provided are based on test report and reference. The user should test sample before bulk trial.

Basic Ramming Mass

Get Price Quote

Get in touch with us, if you are looking for a reliable name offering Basic Ramming Mass at economical rates. We are operating as a Manufacturer & Supplier of Basic Ramming Mass that is prepared at our own facility under the strict vigilance of trained professionals. Owing to our capacious storage facility, we are capable to process small as well as bulk requirements of clients. Besides, clients can provide specific details related to packaging and labeling; we guarantee to work accordingly.

Silica Ramming Mass

2,000 Per Metric Ton

10 Metric Ton (MOQ)

Basic Ramming Mass

36,000 Per 1000 Kilogram

Our product is manufactured at our works as per the requirement of or customers say tailor make material. We are catering to various steel casting unites and foundries in india and are in this field for the past 25 + years

Acidic Ramming Mass

Get Price Quote

Silica Sio2 - 99.30 % Alumina AlO2 - 0.04 % Ferric Oxide Fe2O3 - 0.03 % Titanium Dioxide Tio2 - 0.08 % Manganese Oxide MnO - Nil Calcium Oxide CaO - Nil Manganese Oxide MgO - 0.11 % Sodium Oxide Na2O - 0.05%