Ribbon Blender

25,000 - 500,000 Per piece

1 Piece (MOQ)

Stainless Steel Ribbon Blender Mixer

Get Price Quote

1 piece (MOQ)

Best Deals from Ribbon Blender

Ribbon Blender

Get Price Quote

We are offering ribbon blender we have a state-of-the-art manufacturing facility, which helps us providing our clients with ribbon blenders. Ribbon blenders available size from 200 mm diameter to 2500 mm diameter in mild steel & stainless steel.

ribbon blander

Get Price Quote

Check out our comprehensive array of Ribbon Blander that is price tagged reasonably. We are one of the sought after Manufacturers, Suppliers and Exporters of the Ribbon Blander from Gujarat. Made of stainless and mild steel, these Ribbon Mixers are not only durable, but, also assure speedy and uniform mixing of ingredients. We appease the global demands by furnishing the Ribbon Blander in various capacities.

Ribbon Blender

Get Price Quote

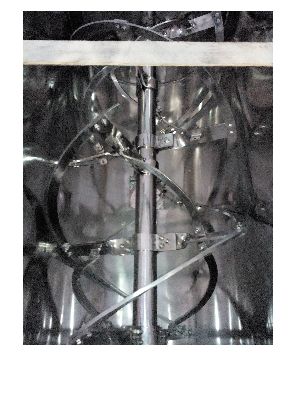

The RIBBON BLENDER is an efficient and versatile blending machine for mixing of dry granules & powders homogeneously. Approximate two third of the volume of the container of Ribbon Blender is filled to ensure proper mixing. The Ribbon Blender gives best result for mixing of dry powder & granules due to the design and shape of the mixing ribbon and product container. It can be used for Pharmaceutical, Food, Chemical and Cosmetic products etc. Material should be charge from the top side. There are port/ports should be provided on the top cover to charge the material as well as for air vent. One discharge valve provided at the bottom side at center of the container. The discharge height could be adjust as per the requirement, so that material gets discharge in the other container directly, so that material handling time for discharge is nil and the operation is dust free In Ribbon Blender the powder moves from center to the end of container and end of container to the center of container. Hence requirement of total mixing time is very less and the RPM required are also very less. The dry material gets sufficient continuous movement due to the shape & movement of ribbon & shape of the container. Which moves material for good quality of blending? The unit is consist of one electrical motor, one worm reduction gear, belt drive between motor and gear, couple drive between gear to ( ribbon ) mixing stirrer. Container having four nos. of legs with discharge valve & top cover. Both end of mixing shaft is sealed with bush & PTFE gland housing & safety guards are provided on all moving parts.

Ribbon Blender

380,000 Per Piece

1 Piece(s) (MOQ)

The Mahavir ribbon blender are based on a proven agitator construction that provides a triple mixing action thus ensuring fast efficient blending. The dimensions and configuration of the ribbons in ribbon blender are carefully balanced to provide a movement of material within the container that avoids dead spots and gives rapid product discharge. The design of the Mahavir ribbon blender can in corporate features required for a customer's product or process such as: wear resistance, corrosive resistance, vacuum filling and discharge arrangements, special shaft seals, heating/cooling jackets. Ribbon blender is available in sizes 100-8000 litters in Stainless Steel 304, Stainless Steel 316 and Mild Steel Construction.

Ribbon Blender

Get Price Quote

This is a universally accepted mixer which is useful for mixing, blending and reaction of solid-solid and solid-liquid materials. They are made in different sizes according to its requirement of application. It has a U shaped trough and a shaft with ribbons is rotating inside it. The ribbons have co-axial supports that provide the strength to the curved arms. The ribbons are designed and fabricated such that the particles inside the shell move freely from one corner to another one and get in close contact with each-other and thereby are mixed very well. Also the close contact enables better reactivity among them.

Ribbon Blender

Get Price Quote

Ribbon blender is used for uniform, homogeneous and quick mixing of powders and semi-wet materials of different densities by specially designed helical ribbon agitator. It can be used for Pharmaceutical, Food, Chemical, Dyestuffs & Pigment etc. For Pharmaceutical Industries, Ribbon Blender is called as Mass Mixture. Uni-Mech manufactures Continuous type and Batch type Ribbon Blenders. Uni-Mech also designs Ribbon Blenders for Chemical Reactions with Heating & Cooling applications. Ribbon Blender Design Range : Capacity range: 5 liters to 15000 liters Material of Construction: Various grades of Stainless Steel, Mild Steel, Hastelloy (cGMP model is also available). Special Features : Homogeneous Mixing Dust Free Operation Easy Handling & Operations Top Charging & Bottom Discharge through Butterfly Valve / Sliding Gate

Ribbon Blender

560,000 Per Piece

Ribbon Blender

150,000 - 7,500,000 Per piece

1 Piece (MOQ)

Ribbon Mixer

Get Price Quote

The design of the Reaction blender also makes suitable to dry stage reaction for the application such as starch, gum and cellulose derivatives. We also offer a various range of accessories such as liquid spray system, controlled rate discharge device, jackets to control or to vary the temperature of the mass.

Double Ribbon Blender

550,000 Per Piece

1 Piece (MOQ)

Ribbon Blender

150,000 - 500,000 Per Piece

1 Piece(s) (MOQ)

Ribbon Mixer

Get Price Quote

All type of Blenders are available for Mixing i.e. Octagonal Shape, V Shape, Double Cone, Cage, Cone & Ribbon Blender in the MOC of Contact Parts S.S.316.

Ribbon Blender

Get Price Quote

We are offering we ultra febtech - an iso 9001:2008 certified company engaged in manufacturing of ribbon blender to mixing equipment machinery .the design of the reaction blender also makes suitable to dry stage reaction for the application such as starch, gum and cellulose derivatives. We also offer a various range of accessories such as liquid spray system, controlled rate discharge device, jackets to control or to vary the temperature of the mass.

Ribbon Blender

Get Price Quote

We Ultra Febtech - An ISO 9001:2008 Certified Company Engaged in Manufacturing of Ribbon Blender to Mixing the Material.The design of the Reaction blender also makes suitable to dry stage reaction for the application such as starch, gum and cellulose derivatives. We also offer a various range of accessories such as liquid spray system, controlled rate discharge device, jackets to control or to vary the temperature of the mass.

Ribbon Blender

Get Price Quote

Working Principle & Features of Techno Enterprise’s Ribbon Blender: Ribbon Blenders is design to provide high mixing efficiency, blending small proportions into large stocks. Ribbon Blender is primarily designed for use with dry materials, although gas and liquid streams can also be introduced. A wide variety of configurations, for either batch or continuous mixing, are available. Application specific rotor mixing element design allows shorter batch cycle times due to increased mixing efficiency. Efficient mixing also provides good heat transfer through optional ASME Code designed jackets for heating or cooling applications. The compact and robust construction dust proof operation ensures their negligible running costs. We can offer these in various customized sizes/finishes. We provide custom made size design of the Ribbon Blender to meet your specific mixing requirements. Mixing vessels can be standard U-shape or cylindrical depending on internal pressure or vacuum requirements. Material finishes available ranging are from industrial coatings to dairy grade polishes. The classic Ribbon Blender serves multi-purpose uses in the manufacture of food, beverage, pharmaceutical, cosmetic, chemical, plastic, agricultural and other products. Given its versatility and economy, the Ribbon Blender is often the choice for most straightforward blending requirements. In a well-made Ribbon Blender, precisely designed and fabricated ribbons turn within a close-tolerance horizontal trough to produce a balanced lateral and radial movement of the batch materials. Blending cycles are relatively fast and mix quality is not hard to duplicate from batch to batch. In principle, it requires very little maintenance even when subjected to frequent product changeovers. Scaling up from a pilot Ribbon Blender operation to large volume production is also generally uncomplicated. Despite these proven advantages, as with other types of mixers and process equipment, optimal mixing performance in the Ribbon Blender still starts with proper sizing, specification and customization. This white paper outlines some strategies for achieving just that, operating to maximum efficiency and ensuring a long service life out of your Ribbon Blender. Ideal For: Seeds and Spices Adhesives Food products Animal feed Chemicals Dry and Wet Pigments Starch Products Pesticides and fertilizers Cement Industries Many Other Wet and Drying Applications as below:

Ribbon Mixer Blender

Get Price Quote

Ribbon Mixer Blender Uniform Dry Mixing Process Application & Process : Ribbon blender mixer is used for uniformly dry mixing and blending applications in the pharmaceutical, chemical, cosmetic, food, pesticides, detergents, and plastics industries. The Ribbon Blender comprises of a U-shaped horizontal trough, specially designed Double Helical Ribbon Agitator, rigid fabricated structure motor, gear box. In operation, material is filled to the top of the outer ribbon. The shaft rotates at relatively low speed and the moving ribbons push the material back and forth mixing it. The outer ribbon rotation displaces the material from the ends to the center while the inner ribbon rotations move the material from the center to the ends. This counter-current action results in homogenous blending. Mixing is achieved in 15 to 20 minutes with 90 to 95 % or better homogeneity. The bottom discharge provided for unloading of the material and easy cleaning of the mixing drum. Specially designed self adjusting sealing arrangement of unique design is provided to ensure that no black particle enters into the mixing drum. Salient Features : Available in Capacity 50 kg to 5000 kg. model. Design is cGMP - Current Good Manufacturing Practices compliance. All contact parts AISI 316 & non contact parts AISI 304. Uniform dry maxing process. The shape of container and mixing stirrer gives sufficient continuous movement to the powder / granules result in good quality. Minor ingredients are dispersed homogeneously without the need for pre-mixing Double or triple action with blending occurring in the small voided areas immediately behind the blending ribbons. The interlocked acrylic covers of product container, enclosed drive& Overloads relay protection. Optional Features : Orientation of discharge is in side or centre. AC Frequency Drive with Variable speed, Jacketing for heating & Cooling, Vacuumized operation. PLC controls with HMI Touch Screen. Flame Proof Electrical. Safety Features : Total drive transmission system enclosed Limit switch installed in the top lid ensure lid is closed Overload relay Protection and Emergency stop button

Ribbon Blender

Get Price Quote

The design of the Reaction blender also makes suitable to dry stage reaction for the application such as starch, gum and cellulose derivatives. We also offer a various range of accessories such as liquid spray system, controlled rate discharge device, jackets to control or to vary the temperature of the mass. Application In: Food, Pharma, Chemical, Minerals, Guar Gum / Starch / Cellulose etc.

Ribbon Blenders

Get Price Quote

The entire unit is fabricated with engineering precision. Along with the double ribbons that provide to & fro, up & down movement to the powder. Two of Chopper Blades moving at cutting speed are provided at diagonally opposite sides to break lumps of the mixture. It accurately and rapidly blends small proportions into large stocks. Ribbon Blender is also suitable to mix a small quantity of liquids to powder stocks. Offers you dust free operation, compact and excellent appearance. This low operative cost equipment is available with the sizes varying from a tiny lab model to 15000 liter.

Ribbon Blender

Get Price Quote

We offer a ribbon blender to our clients for their various industrial needs. The ribbon blender and their sides are manufactured by us from Stainless or Mild steel materials. It comprises of a stainless steel or mild steel centre shaft fitted with specially designed agitator blades for providing the contra flow action. These blenders are equipped with a couple of ribbons. The outer ribbon moves the ingredients into the blender whereas, the inner ribbon constantly circulate the material. The drive of these consists of a gear box coupled with a heavy-duty motor. These blenders are provided with stuffing boxes on its either ends to prevent leakage. It also consists of a hopper and a discharge for loading and unloading of the processed material. Features: Provide homogeneous & quick mixing/blending. Sturdy & vibration free Provide flawless working Easy and economical maintenance High productivity and quality Applications: Chemicals Minerals Spices Sugar industries Pharmaceuticals Pulp and paper industries

Ribbon Blender

Get Price Quote

We Ultra Febtech - An ISO 9001:2008 Certified Company Engaged in Manufacturing of ribbon blender for mixing machinery.The design of the Reaction blender also makes suitable to dry stage reaction for the application such as starch, gum and cellulose derivatives. We also offer a various range of accessories such as liquid spray system, controlled rate discharge device, jackets to control or to vary the temperature of the mass.

ribbon blender machine

200,000 Per Units

U-Mixer Cum Ribbon Blender

Get Price Quote

Very widely preferred machine for mixing and blending solid-to-solid different powders or to blend a small quantity of liquid with huge quantity of powder. Most economical way of mixing the powder if the moisture contain is not high. Available in different construction like SS 304, SS 316 etc. If require, heating or cooling jacket may be provided.

MS Ribbon Blender

90,000 Per UNIT

1 UNIT (MOQ)

Ribbon Blender

Get Price Quote

We Ultra Febtech - An ISO 9001:2008 Certified Company Engaged in Manufacturing of Ribbon Blender to Mixing the Material.The design of the Reaction blender also makes suitable to dry stage reaction for the application such as starch, gum and cellulose derivatives. We also offer a various range of accessories such as liquid spray system, controlled rate discharge device, jackets to control or to vary the temperature of the mass.

Ribbon Blender Mixer

150,000 Per Piece

Ribbon Blender

750,000 Per unit

2 unit (MOQ)

Ribbon Blender

75,000 Per Piece

Ribbon Blender

Get Price Quote

We Ultra Febtech - An ISO 9001:2008 Certified Company Engaged in Manufacturing of Ribbon Blender to Cmixing machinery.The design of the Reaction blender also makes suitable to dry stage reaction for the application such as starch, gum and cellulose derivatives. We also offer a various range of accessories such as liquid spray system, controlled rate discharge device, jackets to control or to vary the temperature of the mass.