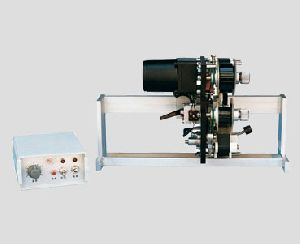

thermal transfer overprinter

Thermal Transfer Over printer is suitable for all intermittent applications within the food, pharmaceutical and cosmetics industries and has the capability to code both Julian date codes and 2D Data Matrix codes. UCS1 Features: Thermal Transfer Overprinter is suitable for all intermittent applications within the food, pharmaceutical and cosmetics industries and has the capability to code both Julian date codes and 2D Data Matrix codes.

...more

Thermal Inkjet Printer

Application : Industrial

Country of Origin : Made in India

Brand Name : Rishi Packaging

...more

The PZ Pilot hi-resolution ink jet printer

Lets You Have It Your Way PZ Pilot Plus printing system is a perfect fit for manufacturers and contract packagers who are looking to print high-quality bar codes, clean and clear logos and razor-sharp text byautomatic Batch Coding Machine. Users select between systems designed to print on porous or non-porous surfaces, providing the ultimate level of flexibility and versatility that customers have come to expect from Squid Ink. Printing That Is Simple and Versatile Squid Ink’s innovative PZ Pilot Plus offers a simple alternative for your case coding and product marking applications. PZ Pilot Plus is capable of printing up to 8 lines of print, for a total print height of up to 1.4″, on virtually any porous or non-porous substrate. PZ Pilot Plus requires minimal setup and is available with a portable, easily adjustable stand, or with mounting brackets that allow you to easily bolt it right to a conveyor. Best of all, the handheld input device and software is designed for people who run packaging lines, not computers, making everyone involved a smooth operator Help Your Product Look Its Best Using industry proven shared-wall technology, the PZ Pilot Plus offers better print quality than competitive high-resolution printing systems. With 256 addressable jets, PZ Pilot Plus boasts 180 dpi print resolution. The result is a system that produces razor-sharp text, scannable bar codes, and the cleanest logos and graphics on the market today. Your Low Maintenance Alternative If maintenance issues are consistently slowing down your production line and are costing you critical time and money, the PZ Pilot Plus is the flexible and reliable alternative you’ve been looking for. PZ Pilot Plus is a fully modular system that allows users to make a fix in less than five minutes, therefore eliminating the need for costly service calls or complete system repair. For most applications, daily maintenance is reduced to a one-time, 30-second printhead purge that is quick and easy to do. Industrial-Strength Operation Tired of inconsistent print on your cases? Unlike competitive high-resolution printing systems, PZ Pilot Plus’ printhead technology is not susceptible to vibration and will not easily lose its prime. In addition, PZ Pilot Plus’ compact printheads don’t require a lot of space in crowded package printing environments. You can be confident that PZ Pilot Plus’ rugged design will withstand the most abusive industrial environments. Affordable Ink Jet Printing If you have wanted to start printing logos or highresolution bar codes on your products, but felt your budget restricted you from doing so, the PZ Pilot Plus offers a new level of economy. PZ Pilot Plus allows users to eliminate the need for pre-printed cases or expensive labeling equipment by printing specific product information directly onto the substrate. In addition, PZ Pilot Plus utilizes ink manufactured directly by Squid Ink, eliminating the costs caused by multiple layers of distribution. Any way you look at it, Squid Ink’s PZ Pilot Plus provides users with an affordable solution to meet their ink jet printing needs. PZ Pilot Plus Printing System Components » Controller system with detachable ink reservoir» 128 or 256 printhead with data cable and ink line» Photocell product sensor and photocell mounting bracket» Industrial-strength handheld input device

...more

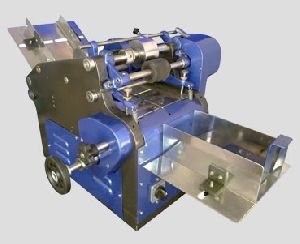

Semi Automatic Batch Printing Machine

Specification : Print Area 35mm X 35mm, 35mm X 50mm, 35mm X 100mm, 50mm X 50mm, 50mm X 100mm Printing Speed : Easily adjust the speed on regulator Min.5 Max.100 imprints per minute. (Depending on skill of operator)

Power : 230V AC±10%(50 Hz) Single Phase.

Weight : 13.300Kgs.

...more

ribbon printing machine

Ribbon hot printing machine suitable to neat, sharp & registered print Batch Number, Date Of Manufacturing, Expiry Date, Prices, best before dates, traceability codes, batch codes & other statutory information with the help of the Characters with Aid of Brass Letters. Manual Coding Machine used for pouches, sachets, aluminium foil, plastic film etc. It is operated by manually. Hot foil ribbon printing machine is very easy no need refilling ink because it has ribbon and it is very easy to change. Manual batch coding machine can print very clear impression. It can print 1 to 3 lines and each line has 1 to 12 characters fonts’ size of 2mm and 3mm. Manual Ribbon Hot Printing Machine very easy to operate those whose production requirement of approximately 1000 to 1500 pieces per day to print help with special hot foil ribbon for strong and permanent marking on most shiny surfaces, including shiny papers, most plastics. Ribbon Hot Printing Machine is one type of hot stamping system.

...more

Ribbon Hot Printing Machine

Power : 40 W

Pneumatic Online Contact Coding Machine

Pneumatic Coding Machine is use of automatic on-line contact coding machine for neat, sharp & registered print Batch Number, Date of Manufacturing, Expiry Date, Prices, best before dates, traceability codes, batch codes & other statutory information the help of grooved Rubber or Nylon flat Stereos. Online batch coder can be install on Form-Fill-Seal machine (FFS Machine) of any stop & go roll moving system to print help with special batch coding ink and Ink activator for reducer ink viscosity it stronger than permanent marker ink on most shiny surfaces, including shiny papers, most plastics. Print Area: 35mm X 35mm Output speed: 100 per minute Prints Letters: Easily Changeable grooved/flat rubber/nylon stereos. Inking Medium: Refillable ink cartridge. Printing Media: Quick Drying Ink (Black Red, Violet, Green) Ink Consummation: Approx 15000 impression / 20 ml depend upon printing matter. Net Weight: 4KG.

...more

Online Coding Machine

Hot Ink Roll Coder Online Machine is use of automatic on-line contact coding machine for neat, sharp & registered print Batch Number, Date of Manufacturing, Expiry Date, Prices, best before dates, traceability codes, batch codes & other statutory information the with the help of the Characters with Aid of Brass Letters. The Print wheel equipped to Dry-Ink Coding Machine can be used for both R arrange and T arrange of characters.

...more

Handy coder Machine

To mark variable information like Batch No., Date Of Manufacturing, Exp. Date, Name & Address Of Consignor, Consignee, Product Name/Code, Shipping Marks, Nett Weight, Gross Weight Etc., on porous (absorbent) & non-porous (non-absorbent) surfaces. Applications : Corrugated Carton, Plywood, Hessian (Gunny), Paper Bags, Wooden Case, Wooden Crate, HDPE Woven, Non-Woven Sacks, Metallic, Plastic Drums, Barrels Sheets, Rubber etc. DIFFERENCE BETWEEN ABSORBENT INK ROLLER & NON-ABSORBENT INK ROLLER: Absorbent Ink Rollers are used for marking absorbent/porous substrates like Corrugated Cartons/Wooden Boxes/Wooden Crates/Paper Bags/Paper etc.. The material of construction is a compound mixture of soft plastics and solvents. Non-Absorbent Ink Rollers are used for marking non-absorbent/non-porous substrates like HDPE Woven /Non-Woven Sacks/Metals/Plastics etc... The material of construction is a compound mixture of hard plastics and solvents. Function: Very compact, light weight friendly and compose almost any type of information that you wish to mark. To mark variable information like Batch No., Date of Manufacturing, Exp. Date, Name & Address of Consignor / Consignee, Product Name / Code, Shipping Marks, Nett Weight / Gross Weight Etc., On porous (absorbent) and non-porous (non-absorbent) surfaces. Applications: Corrugated Carton, Hessian (Gunny)/ Paper Bags, HDPE Woven/ Non-Woven Sacks, Wooden Case/ Wooden Case/ Wooden Crate, Plywood, Metallic/ Plastic Drums/ Barrels/ Sheets/ Rubber etc.

...more

Large Character Ink Jet Printer

High Quality Print on Any Type Of Product Squid Ink’s SQ/2 ink jet printing system allows manufacturers to print high quality dot-matrix characters on a variety of products at a cost-effective price. In fact, the SQ/2 offers the lowest price per printed character in the industry today. Users can choose between two models: a water-based system for printing on porous surfaces like corrugated cartons, paper or wood, or a solvent-based system for printing on non-porous products like plastics, stretch wraps, metals, glass or more. User Flexibility SQ/2 large character ink jet printer users also have the option of choosing from several printhead configurations. Three different print sizes are available: 3/4″, 1/2″ or 3/8″ character height. All printheads are capable of printing both a 7 x 5 and 5 x 5 character matrix, offering print sizes ranging from 1/4″ to 3/4″ in height. Users also have the flexibility to run one or two printheads at any time. All of these components are field-installable for future upgrade to meet your application’s changing requirements. User-Friendly System The SQ/2 is designed for simple day to day operation. SQ/2’s state of the art input device provides quick and easy message programming and retrieval for up to 64 messages. Resident software in the input device walks the user through a series of prompts to program and save each message for printing ondemand. The system can also be programmed and maintained with a PC through a standard RS-232 port. Innovative Technology And Proven Reliability Patented micro-channeling technology eliminates the need for a costly array of fluid valves. Squid Ink uses its own proven plunger technology and distributes ink through a series of channels, keeping production and maintenance costs to a minimum, especially when compared to the costly valve technology common in most ink jet printers today. No More Service Calls The SQ/2 was engineered inside and out for industrial-strength operation. Heavy-duty gauge coated steel cabinetry ensures continuous operation in harsh, real world environments. If the printer does fail, a fix can be completed in less than five minutes. Quick and easy-to-install replacement printheads, PC cards and air pump modules minimize downtime and eliminate costly service calls. Best of all, the water-based SQ/2 utilizes Squid Ink’s patented SQ-60™ no-clog ink, allowing users to leave the ink in their printheads for an extended period of time without flushing or cleaning, making it the most cost-effective, low maintenance ink jet printing system available today. SQ/2 Printing System Components • Controller cabinet and ink delivery system• One or two printhead(s) and printhead mounting bracket(s)• Printhead data cable(s) and ink line(s)• Photocell product sensor and photocell mounting bracket• Industrial-strength hand-held input device SQ/2 Printing System SpecificationsPrinter Type Large character ink jet printerCharacter Height .75″ (1.9cm) in 7 x 5 matrix; .5″ (1.3cm) in 5 x 5 matrix, or.5″ (1.3cm) in 7 x 5 matrix; .375″ (1cm) in 5 x 5 matrix, or.375″ (1cm) in 7 x 5 matrix; .25″ (.6cm) in 5 x 5 matrixCharacter Set 61 character ASCII setPrint Speed 20 feet/minute (6.1m/minute) to 200 feet/minute (61m/minute) line speed; optional extended characterwidth firmware allows for print speeds slower than 20 feet/minuteMessage Length 60 characters per message; 64 memory locationsCommunication RS-232C, 9600 baud, 8 data bits, 1 start, 1 stop, AsynchSoftware Features 24-hour clock, Julian date, counter, lot counterOperating Features Dot size, print delay, character width, photocell on/off, invert print, reverse print, purge routineSQ/2 Exchange Program Eliminates the need for costly service calls and minimizes downtime; troubled printheads andcomponents can be replaced in less than 5 minutesController Dimensions 12″ (31cm) H x 12″ (31cm) W x 5.25″ (13cm) DController Weight 10.5 lbs. (4.8kg)Printhead Dimensions 3″ (7.6cm) H x 1.6″ (4.1cm) W x 7″ (17.8cm) L; dimensions are for the printhead only – an additional3″ (7.6cm) is needed for the ink line and cabling which extends from the back of the printheadProduct Sensor Diffuse beam photocell (24v) or hardware sinking signalElectrical Requirements 110/120 VAC, 50/60Hz, 1.6 ampCabinet Construction Industrial gauge coated steelOperating Environment 38°F (3°C) to 122°F (50°C)Substrate Capabilities Porous or Non-Porous surfacesAir Requirements No external air neededInk Capabilities Porous: Squid Ink SQ-60™ no-clog inkNon-Porous: Several Squid Ink solvent based fluids to meet adhesion and dry time needsInk Volume .5 (1.89 liters) gallon bottle standard; available upgrade (water-base ink only) to 5.0 gallon pail(18.93 liters) SQ/2 Optional AccessoriesSpare Parts Kit Includes spare printhead, card cage and PC board pack, air pump module, data cable and master capStarter Kit Includes ink, cleaner for flushing the system, spray bottle for cleaner, hand cleaner and lint-freewipes for the printhead5-Gallon Pail Upgrade Upgrades ink supply to 5.0 gallons (water-base ink only)PC Software Communications software for PC integrationRepeat Print Firmware Allows continuous printing of messagesExtended Character Allows for print speeds slower than 20 feet/minuteWidth FirmwareRollaway Stand Provides mount for the SQ/2 controller, designed with caster wheels for transportation within plant

...more

Label Coding Machine

Automatic Batch Coding Machine suitable to neat, sharp & registered print Batch Number, Date Of Manufacturing, Expiry Date, Prices, best before dates, traceability codes, batch codes & other statutory information with the help of Rubber or Polymer flat Stereos. Machine with automatic feeding System, Stack of Pouches is pulled or pushed by roller & collected from the tray after printing the message. Automatic Batch Coder can be Use as a conveyor for Inkjet printer like automatic feeding Machine or Stacker Machine, Automatic contact coding machine is complete solution for print labels coding and marking needs in the pharmaceutical industry, Food and grocery industry, Fresh Produce, Frozen Food, bakery products, Cosmetics bottle labels, cartons and pouches. Batch coder machine for the production requirement of approximately 10000 to 25000 pieces per day to print help with special batch coding ink ( paste ink or Liquid Ink )and Ink Activator for reducer ink viscosity it stronger than permanent marker ink on most shiny surfaces, including shiny papers, most plastics. Automatic Labels, Cartons & Pouches Coding Machine installs mechanical arrangement to print at the accurate place.

...more

intermittent printing machine

Incorporating break through design on the coder resulted in the birth of an unparallel product UCS1 online thermal transfer overprinter that provides customers in the food and pharmaceutical industry etc high consistent print cycle rate and unmatched print quality.

...more

Industrial Inkjet Printer

Industrial inkjet printer the Citronix ci580 is a smart-featured continuous ink jet printing System (CIJ). Designed To meet a broad range of applications, the ci580 features the most common needed functions and capabilities necessary for the typical identification, lot date code, sell-by date printing applications.

...more

PZ Pilot Plus printing system

Ci580 : Industrial inkjet printer the Citronix ci580 is a smart-featured continuous ink jet printing System (CIJ). Designed To meet a broad range of applications, the ci580 features the most common needed functions and capabilities necessary for the typical identification, lot / date code, sell-by date printing applications. Printing : Continuous Inkjet Printer the ci580 prints 1 or 4 lines of print and has the ability to print 1/2" (12mn) images. Text, Graphics and Bar codes are possible. Speeds in excess of 1200 ft/minute can be achieved with 1 line of print and 200 ft/ minute with 4 lines of print. Selections of MEK, Acetone or Ethanol based links are available for immediate dry times and superior adhesion to a variety of substrates. Interface : True WYSIWYG message editing with drag and drop field based structure provide the user the most convenient and versatile message formatting available. A large quarter VGA graphical display with icon-based operations and full size QWERTY style keyboard assure effortless operations. Fast, single start and stop buttons provide the user an efficient start up and shutdown routine. Designed for a global market, the ciSeries systems feature multiple language formats. Print multi-national characters, custom graphics at the touch of a button. Integrated as standard, the ci580 have RS232, a photocell input, shaft encoder, three programmable alarm outputs and I Solid state relay output. Design : Inkjet Batch Coding Machine the ci580 is housed in an IP55 (NEMA 4) rated enclosure for operations in extreme wet or dry applications. state-of-the-art single board surface mount electrical technology coupled with integrated smart print head and ink system components monitor critical operating functions. The print head can mount in any orientation or environment. A heating mechanism allows operations in cold areas. Smart Flush : Small character inkjet printer the ci580 systems feature the proprietary SmartFlush printed maintenance operations. Makeup solvent is used to clean the print head, nozzle and gutter at start up and shutdowns providing a consistent, reliable daily start up.

...more

Hot Stamping Machine

Ribbon Hot Printing Machine (Motorized) Printing Type: Colour Ribbion Printing, Type Size (mm) : 2x1.5(8PT) 2.5x2(9PT), Type Number : Line 2 x 4 Max 15 Characters, Two Line 2 x 4 Max 30 Characters, Three Line 2 x 4 Max 45 Characters

...more

Hot Roll Coding Machine

Hot Roll Coding Machine suitable to neat, sharp & registered print Batch Number, Date Of Manufacturing, Expiry Date, Prices, best before dates, traceability codes, batch codes & other statutory information with the help of the Characters with Aid of Brass Letters. The Print wheel equipped to Dry-Ink Coding Machine can be used for both R arrange and T arrange of characters.In T arrange Solid-ink Coding Machine can print 1 to 10 characters in each line. In R arrangeSolid-ink Coding Machine can print 1 to 8 characters in each line. Automatic Labels & Pouch Dispensing Machine with automatic feeding System, Stack of Pouches is pulled or pushed by roller & collected from the tray after printing the message. It is sensor base machine so it takes one by one and prints at the accurate place. It also adjustable printing and it is also having auto counting. Automatic Coding Machine used for thin cardboard, aluminium foil, printing label on paper and plastic film dry ink coding very high resolution, fast printing, fast dry can be select and strong impression. Stacker Machine is complete solution for print labels coding and marking needs in the pharmaceutical industry, Food and grocery industry, Fresh Produce, Frozen Food, bakery products, Cosmetics bottle labels, cartons and pouches. Batch coder machine very easy to operate those whose production requirement of approximately 10000 to 25000 pieces per day to print help with special dry ink cartridge for strong and permanent marking on most shiny surfaces, including shiny papers, most plastics. Automatic Dry-ink Coding Machinecan be used to print notes such as production date, lot number on the plastic and paper bags, in food and pharmaceutical industries. The words printed are clear and endurable against wear and tear.

...more

Hot Ribbon Coder

Ribbon hot coding machine suitable to neat, sharp & registered print Batch Number, Date Of Manufacturing, Expiry Date, Prices, best before dates, traceability codes, batch codes & other statutory information with the help of the Characters with Aid of Brass Letters. Pneumatic Coder & Hot Foil Coder on Form-Fill-Seal machine (FFS Machine) of any stop & go roll moving system. Hot foil ribbon printing machine is very easy no need refilling ink because it has ribbon and it is very easy to change. Foil Printing Machine can print very clear impression. online Batch Coding Machine can print 1 to 4 lines and each line has 1 to 12 characters fonts’ size of 2mm and 3mm. online Coding Machine very easy to operate intermittent production line to print help with special hot foil ribbon for strong and permanent marking on most shiny surfaces, including shiny papers, most plastics. The words printed are clear and endurable against wear and tear. Printing speed is adjustable. Have feature of synchronous & precise printing. Online Hot Ribbon Coder have feature of synchronous & precise printing.

...more

hot ink roller

Hot Ink Roll Coder Online Machine is use of automatic on-line contact coding machine for neat, sharp & registered print Batch Number, Date of Manufacturing, Expiry Date, Prices, best before dates, traceability codes, batch codes & other statutory information the with the help of the Characters with Aid of Brass Letters. The Print wheel equipped to Dry-Ink Coding Machine can be used for both R arrange and T arrange of characters.

...more

hot ink roll coder

Hot Ink Roll Coder / Online Machine is use of automatic on-line contact coding machine for neat, sharp & registered print Batch Number, Date of Manufacturing, Expiry Date, Prices, best before dates, traceability codes, batch codes & other statutory information the with the help of the Characters with Aid of Brass Letters. The Print wheel equipped to Dry-Ink Coding Machine can be used for both R arrange and T arrange of characters.In T arrange Solid-ink Coding Machine can print 1 to 10 characters in each line. In R arrangeSolid-ink Coding Machine can print 1 to 8 characters in each line. It is sensor base machine so it takes one by one and prints at the accurate place. Automatic online Coding Machinecan be install on Form-Fill-Seal machine (FFS Machine) of any continues roll moving system on paper and plastic film dry ink coding very high resolution, fast printing, fast dry can be select and strong impression. Lock-And-Follow Solid-Ink Coding Machine is complete solution for print coding and marking needs in the pharmaceutical industry, Food and grocery industry, Fresh Produce, Frozen Food, bakery products to print help with special dry ink cartridge for strong and permanent marking on most shiny surfaces, including shiny papers, most plastics. The words printed are clear and endurable against wear and tear. Printing speed is adjustable. Have feature of synchronous & precise printing. Specification: Voltage (V/Hz) AC 220/50 Power (W) 180 Solid Ink Roller (mm) 35×32×16 Printing Speed (pieces/min) ≤250 or 12.5m/min Max Width of Packing Film: 450mm Max. Printing Line T Arrange (10.5PT):11Lines (Max.10 characters/line)R Arrange (10.5PT):8Lines (Max.8 characters/line) Type Size (mm) 2×1.5(8PT) 2.5×2(9PT) 3×3(10.5PT) 4×2.5(18PT) External Dimensions (L×W×H)(mm): 590×200×280 Net Weight (Kg): 15 kg

...more

Hot Foil Coding Machine

Pneumatic Coding Machine is use of automatic on-line contact coding machine for neat, sharp & registered print Batch Number, Date of Manufacturing, Expiry Date, Prices, best before dates, traceability codes, batch codes & other statutory information the help of grooved Rubber or Nylon flat Stereos. Online batch coder can be install on Form-Fill-Seal machine (FFS Machine) of any stop & go roll moving system to print help with special batch coding ink and Ink activator for reducer ink viscosity it stronger than permanent marker ink on most shiny surfaces, including shiny papers, most plastics.

...more

High Speed Automatic Batch

High Speed Automatic Batch Printing Machine (Single Chain) * 1.5 Feet Length Automatic Batch Coding Machine suitable to Neat, Sharp & registered Print Batch Number, Date Of Manufacturing, Expiry Date, Prices, best before dates, traceability codes, batch codes & other statutory information with the help of Groove Rubber or Polymer flat Stereos. Machine with automatic feeding System, Stack of labels is pulled or pushed by roller & collected from the tray after printing the message. Label Coder can be Use as a conveyor for Inkjet printer like automatic feeder or Stacker Machine. Automatic coding machine is complete solution for print labels coding and marking needs in the pharmaceutical industry and Cosmetics bottle labels. Batch coder machine for the production requirement of approximately 10000 to 25000 pieces per day to print help with special batch coding ink ( paste ink or Liquid Ink )and Ink Activator for reducer ink viscosity it stronger than permanent marker ink on most shiny surfaces, including shiny papers, most plastics. Label batch printing machine are suitable to print almost labels surfaces. Over All Dimension : 820mm X 415mm X 490mm Speeed : 125/180/250 imprints per minute. Printing Media : Fast dry permanent paste ink or Liquid Ink Label Size : Minimum 20mm X 40mm to Maximum 150mm X 200mm Motor : ¼HP/0. 18KV 1440RPM (50Hz) Power : 230 Volts, Single Phase or 400/440 Volts, 3Phase Weight : Approx 75 kgs. Applications : Pharmaceutical Label, Labels & PVC Shrink Sleeves.

...more

Handy Marker

To mark variable information like Batch No., Date Of Manufacturing, Exp. Date, Name & Address Of Consignor, Consignee, Product NameCode, Shipping Marks, Nett Weight, Gross Weight Etc., on porous (absorbent) & non-porous (non-absorbent) surfaces.

...more

Handheld Printer

Handheld Ink‐Jet Printer Reiner speed‐i‐Jet 798 can print on any absorbent surface smooth or irregular. The latest portable inkjet printer technology is now available - Handheld Ink‐Jet Printer pen. Automatic numbering machine works using inkjet technology but operates like a pen, allowing a user to "write" on a surface with consecutive serial numbers, time-stamps, date-codes or just plain text. Batch, date & number Portable Inkjet Pen is capable of printing dates, times and serial numbers, automatically updating these codes after every consecutive print.

...more

Handheld Inkjet Printer

14,000 Per Piece

Application : Industrial

Printing Type : Thermal

Packaging Type : Thermacol

...moreBe first to Rate

Rate ThisOpening Hours