RASN-M Motorised Rockwell Hardness Tester

Get Price Quote

Principal : Rockwell & Rockwell Superficial tests consists of forcing an indentor (Diamond or Ball) into the surface of a test piece in two steps i.e. first with preliminary test force and thereafter with additional test force and then measuring depth of indentation after removal of additional test force (Remaining preliminary test force active) for measurement of hardness value.Brinell test consists of forcing a hardened ball into surface of a test piece with a specified test-force and measuring the diameter of indentation for evaluation of Brinell hardness number.Operation : For Rockwell & Rockwell Superficial Test In case of 'RASN' series machines for Rockwell & Rockwell superficial tests a preliminary test force in first applied and then indicator is automatically set for zero. Quickly thereafter an additional test force is applied without removing the preliminary test force. When the penetration is stabilised, the additional test force is removed and the hardness number is shown directly on the indicator.For Brinell Test : The operation is exactly same as above. However, the diameter of impression is measured outside of machine by Brinell microscope. Brinell hardness number is found out by referring corresponding hardness tables showing hardness number against dia. of indentation for specified ball diameter and test force.'FIE' new 'RASN' series of Hardness Testing Machines come with much improved design and look with following major design changes. : The machine body is having a taper front look and a big size dial gauge in the front. The machine is powder coated for far better look. The paint shade do not fade and machine looks like new over year. The elevating screw of machine is guided in a hardened and ground bush, not allowing movement of elevating screw more than 0.05 mm when raised to full height. The accessory is returned for years together due to hardened bush. A hardened and ground stepped bush is fixed on top of main screw for location and rest surface. This guarantees no change in results due to rough handling of test table or test piece. It means a trouble free long life machine accuracy. An antifriction linear bearing with almost no clearance is provided for a perfect vertical movement of loading plunger with minimum friction. This enable testing of small dia. pin or ball upto 3 mm dia. All machine models are provided with automatic zero setting dial gauge or digital readout. Hence zero setting at every test is avoided. Our Hardness Tester confirm to respective standard as under. IS : 2281, BS 10003-2 & ASTM E-10 for Brinell Test.

Rockwell Hardness Tester

Get Price Quote

Our valued customers are provided with a qualitative range of Rockwell Hardness Testers. These products are perfect for Rockwell and Rockwell superficial tests. Equipped with LCD display, these motorized digital devices are capable of measuring hardness easily and display the results in 0.1 Rockwell unit. Following is the steps involved in the functioning of these: Automatic load selection and automatic zero setting dial gauge with range · Load (kgf ) – 60 ,100 and 150 kgf for Rockwell test · Facility of initial load of 10 kgf · Maximum test height – 230 mm · Depth of throat – 133 mm · Maximum depth of elevating screw below base approximate 240 mm · Power supply: Single phase AC 230V-50 Hz. · Size of Base mm- 170x430(Approx) · Machine Hight – 655 mm · Net Weight (kg) – 65 (Approx) Rockwell & Rockwell superficial test consists of forcing an indentor (Diamond or Ball) into the surface of a test piece in two steps First with preliminary test force Another with additional test force Measuring depth of indentation is done after removal of additional test force (remaining preliminary test force active) for measurement of hardness value

Best Deals from Rockwell Hardness Tester

Rockwell Hardness Tester

225,000 Per Unit

Rockwell Hardness Tester

55,000 Per Piece

Motorized Rockwell Hardness Tester

Get Price Quote

We are the main supplier of this product.

Rockwell Hardness Tester

Get Price Quote

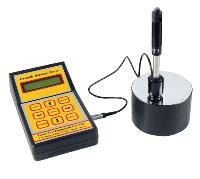

Rockwell Hardness Tester, Portable Metal Hardness Tester

Rockwell Cum Brinell Hardness Tester

Get Price Quote

Rockwell Cum Brinell Hardness Tester, Ferrous DFT Meter, Chlorine Meter

Rockwell Hardness Tester

Get Price Quote

Rockwell Hardness Tester, Colour Matching Cabinet, Toxicity Tester

Automatic Rockwell Hardness Tester

Get Price Quote

Automatic Rockwell Hardness Tester, Electronic Level