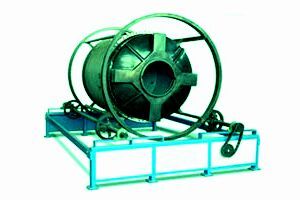

Oven Rock 'N' Roll machine

Get Price Quote

For Open Flame Rock 'N' Roll Machine Pet Is required on the Ground and Overhead Crane / Hoist for Loading and Unloading the Moulds of the Machine. The machine is Easy To Operate, Low Maintenance and Minimum Manpower required to operate. The Ultimate Machine products Large Size Hollow Tanks. Less Installation Cost and Easy Operating System with Control Panel. Machine Available upto 40000 Litres capacity tank Products.

Papad Rolling Machine

15,000 - 35,000 Per Piece

Key advantage of Pedal Type papad / Mathiya / chorafali making press ( Papad Rolling machine) Unique and reliable design The Automatic papad making machines are highly effective as well as non-stop continuous process.Easier operation & less maintenance cost. Continuous production per shift and faster return on investment. Compact design, occupies very little space. A minimized power consummation by the way of friction loses. Low noise operation, no wastage of product and no pollution hazard. Very easy operations, requires no skilled labor.

Best Deals from Rolling Machine

HYDRAULIC ROLL GRINDING MACHINE

Get Price Quote

SPECIAL FEATURES : S.R. & Flame Harden Table Heavy Duty Hydraulic Cylinder / Power Pack Table feed minimum 100 mm/ min to maximum 1500 mm / min Hydraulic Drive. Centralised Lubrication System. Optional Equipment (At Extra Cost) : Magnetic seperator

Mechanical Thread Rolling Machine

Get Price Quote

Papad Rolling Machine

25,000 Per Piece

1 Piece (MOQ)

Rock N Roll Machine

Get Price Quote

Very easy & comfortable machine operating function through digital control & display panel. The process is fully visual to the operator so the monitoring of the products during process leads lesser chances of rejection. Flexibility of different models to produce from 200Ltr. To 25000Ltrs vertical tanks. Efficient low pressure burner which are very simple to adjusted from outside. Faster return of investment due to lesser production cost. Rock N Roll machines are widely used to economically produce the smaller to large size hollow products up to 25000Ltrs. Capacity.

Roll Compactor Machine

450,000 - 1,950,000 Per Piece

1 Piece (MOQ)

Features : CPM Roll Compactor CPM -RC 200/50, 200/75 & 200/100 are GMP Models & 200/150, 200/200. Very compact design available in Plain, Water Jacketed or Flameproof Model. Screw is driven through ACVF Drive. Safety slipping clutch between gearbox and feed screw. Rolls drive through twin's shaft gearbox with speed drive unit coupled to it using coupling, which ensures synchronization of the rolls with a steady torque loading. Pre - den sifter screw comprises of cylindrical or conical shape, which is well polished and made of AISI SS-304 quality material - SS 316 optional. Compacting rolls sleeves are made out of tool steel, hardened to 55 HRC approximately, and are keyed in to shafts and thus protected against axial slipping by thrust plates and bolts. The feed screw assembly can be lifted by hand-operated hydraulic pump. This facilitates ease in cleaning. Scrapper assembly also designed to dismantle for ease of cleaning. Pre-compression chamber guides the powder without any slippage or leakage. A separate panel board which consist all controls and indicators of the compactor are permanently built in namely, on/off rolls, on/off feed screw, main switch, and forward/reverse switch, ammeters for rolls and feed screw and emergency stop to avoid short circuit or fire hazard at the time of cleaning with water. Electrical interlocking between main roll drive and fixed screw drive.Water jacketing arrangement. (optional) Hydraulic power pack system for Rear Roller. (optional) AC Variable frequency drive for Rollers. (optional)

FABRIC ROLL WRAPPING MACHINE

210,000 Per Piece

1 Piece (MOQ)

Metal Roll Forming Machine

Get Price Quote

1 Piece (MOQ)

Spring Roll Making Machine

108,000 Per Piece

1 Piece (MOQ)

paper rolling machine

23,199 - 23,200 Per piece

Plate Bending Rolls

Get Price Quote

The PBM Series 3 Roll Pyramid Type Hydro Mechanical Plate Bending Machines are designed with top roll UP & DOWN movement by hydraulic cylinder. This saves time & labor to adjust top roll. This feature makes the machine more productive and suitable for handling heavy jobs. Dropper end movement is done by hydraulic cylinder.

Cream Roll Packing Machine

270,000 Per Piece

1 Piece (MOQ)

Digital Brush Roller Sanding Machine

Get Price Quote

1 Piece (MOQ)

Fabric Roll Slitting Rewinding Machine

Get Price Quote

As one of the famous in this domain we are offering a wide range of Fabric Roll Slitting Rewinding machine. The manufacture of Slitting Rewinding machine is designed from high grade crude materials and innovative technology with industry standard norms. The offered Fabric Roll Slitting Rewinding machine is approved for saving time, money and energy. Our Roll slitting rewinding machines are widely used for different industry application and the machine have some special features like noise less, less vibration, high strength, sturdy design etc. Furthermore, we are providing this Fabric Roll slitting Rewinding machine at marginal prices. Features Easy to operate Sturdy design Most versatile Cost efficient High strength Noise less and less vibration

Vertical Top Roller Greasing Machine

Get Price Quote

Machine is well designed for convenient, efficient greasing system of Ring Frame and Speed Frame top rollers to grease single side at a time with volumetric calibration, manually easy operate and prevent wastage of grease having tank capacity of 1.6 kg.

Wire & Sheet Rolling Machine- Wheel Drive - Double Head

Get Price Quote

1 Unit (MOQ)

THis machine is Wheel Drive rolling machine and made for Gold & Silver Metal Rolling Process. Rollers are made from duly hardened steel carfted using latest tools & advance technology. Available Sizes : 5X2.75 Inch 6X3.50 Inch 8X4 Inch All the mchine models are designd in complaince with Internaltional Quality Standards.

Woven Bag Roll to Roll Printing Machine

Get Price Quote

01 Set(s) (MOQ)

We are offering woven bag roll to roll printing machine. We at fuma have put all our efforts into making each of our machines the best of its kind. We manufacture printing machines up to six colors. Multi color can be combined freely by changing the direction of cloth threading. When machine stops, the ink transmission mechanism will work continuously and wait for re-start. It can reduce forming waster. Each color can be controlled separately. feature • excellent price – performance ratio. • exceptionally reliable and accurate • very compact and high end technology. • easy maintenance and operator friendly design. • both type of winders offered – machinical and turret. • auto tension control system for unwinder. • perfect registration of print • in-line perforation unit offered as option. • up to 100 mtrmin speed of printing and cutting. • up to 800 mm printing width and up to 1000 mm cutting length. • individual gearbox with inbuilt plenetary system at each printing station. • special designed anilox and ink roller for maximum milage and minimum splashing of ink at higher speed. • both type of ink drying option offered – hot air and infrared heaters. • offered vertical gusseting system as optional. • central control cabinet with ac drive system. • for roll to roll printing, surface winder also offered optionally. • available with both type of bag cutter – for laminated and for unlaminated. • igbt technology based latest corona treater.

spring roll machine

180,000 - 185,000 Per Piece

Top Roller Greasing Machines

65,000 Per Piece

1 Piece(s) (MOQ)

prayosha engineers since 2000 a-127 maruti industrial estate vijay mill compound mfg product :- spinning roll shop equipment , auto cot grinding machine , semi auto cot grinding machine , hydrolic cot mounting machine , top roller gressing machine , u. V top roller treatment machine , spindle oil maintenance machine , motorized eccentricity tapper tester , fluter roller truing machine , flocked clearer roller cleaning machine our spare mfg :- worsted spinning machine spare our export :- india , bangladesh , vietnam , usa , peru , tasken ,pakistan , tazikistan , uzebikistan , iran , usa , south africa , kenya , australiya , egypt , italy , maleshiya , nepal , maxico , sri lank , rawanda , turkey , thailand , turkemistan , syria , poland , germany , botswana

Roll Bars Machine

Get Price Quote

Roll Bars Machine

Tandem Vibratory Roller Machine

500,000 Per Piece

Sheet And Wire Rolling Machine

Get Price Quote

Available with us are Sheet & Wire Rolling Machine in Ahmedabad, Gujarat that are manufactured in tandem with the standards of both national and international market. These machines offered by us are used for making sheets ans heavy duty wires. Customized on technical as well as physical basis, our machines are able to meet the varied requirements of our valuable customers. Features Optimum performance Noise free operations `Low maintenance

Roller Cutting Machine

55,000 Per Piece

1 Piece (MOQ)

jewellery rolling machine

Get Price Quote

Wire & Sheet Rolling Machines

Get Price Quote

The Wheel drive system, Wire & strip winder (optional), Lubrication system (optional), Side roller for designed purpose - Garedi (optional).

Roll Forming Machine

Get Price Quote

roller press machine

Get Price Quote

Standard Features :- It is used to cover laminates / papers / acrylics / veneers / PVC foil on the materials such as MDF, particle board / plywood Hard rubber rollers and four heater elements, that ensures perfect fix of laminates on board. Motorized up / down movement for thickness adjustment. No waiting period like other press, No limit to the workpiece length, easy to use. Consumes less energy as compare to other press. Adjusting roller speed and temperature gives the best results. Easy accessible mobile control Panel for convenient operations. In-feed & out-feed wide conveyers, for mass production.

Steel rolling machine

Get Price Quote

Steel rolling machine, Industrial Machine, Roll Grinding Machine

Rock N Roll Machine

Get Price Quote

✔ Rock N Roll Machine main Frame complete with Rolling mechanism with suitable Gearbox & motor driven with AC variable drive for speed control. ✔ Main supporting tripod frame for fitting the main frame. ✔ Rocking mechanism with hydraulic cylinder. ✔ Complete heating system with burners having individual control System & main regulating valve. ✔ Powder coated Electrical panel with dust proof construction.