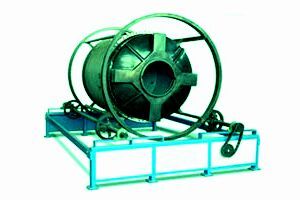

Roll Grooving Machine

Get Price Quote

We are offering wide range of roll grooving machine. Our machine is widely known for some unique features: * long service life * low maintenance requirement * strength with the help of our rich industry experience, we bring forth and exclusive range of roll grooving machine that is extensively used in engineering, electrical and automobile industries. Designed and manufactured by our skilled professionals using quality tested components and high-end technology as per the set industry norms, this roll grooving machine assures longer functional life. This machine is widely appreciated due to its easy usage & maintenance, optimum strength, robust construction, corrosion resistance and durability.

paper rolling machine

23,199 - 23,200 Per piece

Best Deals from Rolling Machine

Spring Roll Making Machine

108,000 Per Piece

1 Piece (MOQ)

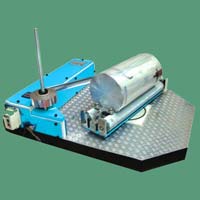

Hydraulic Thread and Form Rolling Machine

Get Price Quote

Standard Equipment: Compact design Fabricated steel frame Versatile for all type of works Manual & Automatic cycles Range of cycle times Extended universal joint provides smooth operation for bib angle of work piece. Over sized coolant tank for superior cooling effects. Low pressure hydraulic power pack to ensure to low heat & minimum maintenance. “T” type and accurately ground slide assures that jumping and vibration will not happen during rolling. Centralized lubrication of all important moving parts. Thread rolling is a chipless cold forming process. A plain cylindrical blank, with a diameter part way between the major and minor diameters of the finished thread, is rotated and squeezed between cylindrical type hardened steel dies whose working surface are the reverse of the thread form to be produced. The threads of the die penetrate the surface of the black as it rolls between them, displacing material to form the roots of the threads, and forcing the displayed material readily outward to form the crests. Unlike other threading process, no material is wasted. Most threads are rolled by the in-feed method in which the entire thread length is formed simultaneously without axial movement of the part. Threads that is too long to be produced by the in-feed method can, however, be rolled by a thru feed method on these type of machine.

Flocked Clearer Roller Cleaning Machine

Get Price Quote

Having association with the leading names enable us to deliver high quality products to our worthy clientele. In addition to this, we procure the basic material from the trusted places only. Customers highly prefer us because of our practice of delivering the orders in an organized condition and on time.

Sheet Rolling Machine

1,250,000 Per Piece

Wire & Sheet Rolling Machine - Single Head

100 Per Unit

1 Unit (MOQ)

High torque Heavy duty motorized rolling machine for Gold & Silver Metal Rolling Process. Rollers are made from duly hardened steel carfted using latest tools & advance technology. Available Sizes : 4X3 Inch (100X75 mm) 5X3 Inch (127X75mm) 6X3 Inch (150X75 mm) 6X4 Inch (150X105mm) 8X4 Inch (200X105mm) All the mchine models are designd in complaince with Internaltional Quality Standards.

spring roll machine

180,000 - 185,000 Per Piece

Roll Compactor Machine

1 Per Piece

Key Features : In compliance with GMP guidelines All covers are designed to obtain dust-free operation Feed screw is steplessly driven through variable frequency drive Hard chome plated & mirror finished compacting rolls made of tools steel Pre-compaction chamber guides the product to rolls without any slippage or leakage Electrical interlocking between main roll drive and feed screw drive Water Jacketing arrangement (optional) Hydraulic Power Pack system (optional) ACVF Drive for rolls (optional)

Papad Rolling Machine

15,000 - 35,000 Per Piece

Key advantage of Pedal Type papad / Mathiya / chorafali making press ( Papad Rolling machine) Unique and reliable design The Automatic papad making machines are highly effective as well as non-stop continuous process.Easier operation & less maintenance cost. Continuous production per shift and faster return on investment. Compact design, occupies very little space. A minimized power consummation by the way of friction loses. Low noise operation, no wastage of product and no pollution hazard. Very easy operations, requires no skilled labor.

Roller Cutting Machine

55,000 Per Piece

1 Piece (MOQ)

Tandem Vibratory Roller Machine

500,000 Per Piece

Cream Roll Packing Machine

270,000 Per Piece

1 Piece (MOQ)

Roll Bars Machine

Get Price Quote

Roll Bars Machine

Sheet And Wire Rolling Machine

Get Price Quote

Available with us are Sheet & Wire Rolling Machine in Ahmedabad, Gujarat that are manufactured in tandem with the standards of both national and international market. These machines offered by us are used for making sheets ans heavy duty wires. Customized on technical as well as physical basis, our machines are able to meet the varied requirements of our valuable customers. Features Optimum performance Noise free operations `Low maintenance

Oven Rock 'N' Roll machine

Get Price Quote

For Open Flame Rock 'N' Roll Machine Pet Is required on the Ground and Overhead Crane / Hoist for Loading and Unloading the Moulds of the Machine. The machine is Easy To Operate, Low Maintenance and Minimum Manpower required to operate. The Ultimate Machine products Large Size Hollow Tanks. Less Installation Cost and Easy Operating System with Control Panel. Machine Available upto 40000 Litres capacity tank Products.

Roll Forming Machine

Get Price Quote

roller press machine

Get Price Quote

Standard Features :- It is used to cover laminates / papers / acrylics / veneers / PVC foil on the materials such as MDF, particle board / plywood Hard rubber rollers and four heater elements, that ensures perfect fix of laminates on board. Motorized up / down movement for thickness adjustment. No waiting period like other press, No limit to the workpiece length, easy to use. Consumes less energy as compare to other press. Adjusting roller speed and temperature gives the best results. Easy accessible mobile control Panel for convenient operations. In-feed & out-feed wide conveyers, for mass production.

JUMBO ROLL SLITTING REWINDING MACHINE

851,000 Per Piece

1 Piece (MOQ)

Salient Features Of Jumbo Roll Slitting Rewinding Machine: · Most Versatile, Model Providing Combination Of Duplex Center Cum Surface Rewind System · Constantly Flawless Slit Rolls By Providing Center Driver Drum To Maintain. Fixed Minimum Distance Between Slitting And Rewind Point · Constant Line Speed Causes Constant Tension Rolls · Two Rewinding Shafts Carried On Swinging Arms Are Center Driven Through Adjustable Slipping Clutch · Counter Balance System To Adjust The Pressure Between Rewind Reels And Center Drum · Suitable For Off Caliper / Slippery / Stretchy Material · In Special Case, Rewinding Shaft Can Be Supplied With Provision Of Individual Different Slip Assemblyfor Each Slit Reels · Slitting Methods As Per Customer Requirement Like: Scissor Cut/Crush Cut (Circular Knives) / Razor Blade Slitting System · Side Frame Construction Of Ribbed Anti Vibrationi Body · Rewind – Central Drum Or Duplex Type · Dynamically Balances Drive Rollers · Trim Separation By Air Blower Of 1.0 Hp Ac Motor · Line Speed Up To 100 – 200 Meter /Min. Depending On The Thickness Of The Materials & Operating Conditions

Cotton Roll Cutting Machine

15,500 Per Piece

1 Piece (MOQ)

jewellery rolling machine

Get Price Quote

Stretch Roll Wrapping Machine

Get Price Quote

We are offering stretch roll wrapping machine :- protection against moisture and dust, prevent telescoping of rolls save packaging cost, labour and time better identifications of wrapped products give suitability to product economical way of packaging available in require size 500mm -600mm-800mm.

Roll Compactor Machine

Get Price Quote

Surgical Bandage Rolling Machine

180,000 Per Piece

1 Piece (MOQ)

Electric Slip Roll Machine

Get Price Quote

We are leading supplier of electric slip roll machine.

Fabric Rolling Machine

Get Price Quote

Fabric rolling machine Feeding - Loose Fold to Delivery - Roll, Surface Winder Unit For Fabric Rolling, A. C. Inverter Drive with Variable Speed and Tension Control, Edge Guiding System - Electrical with Photo Cell Sensor at Winder Unit, Available For Wider Fabric up to 3.6 mtr. Or As per Customer Requirement.

Fluted Roller Truing Machine

Get Price Quote

1 Piece (MOQ)

Hydraulic Fluted Roller Truing Machine

Get Price Quote

Accurate & precise truing of Bottom rollers, Shafts etc. Can handle rollers up to 40 mm diameter. Hydraulic operated press Eccentricity checking gauge is included.

batch roller machine

Get Price Quote

Stainless Steel trough is built up with stainless steel rotary conical roller clockwise & anti clockwise which converts the cooked mass into cone shape. batch roller can be used for tofee and candy.

motorized plate bending roll

Get Price Quote

To cater the variegated demand of our clients, Bhavik enterprise provide high engrossed in providing a huge range of motorised plate bending roll, this machine manufactured by skilled professionals using the modern technology. We can drive and pinch any roll as per application. It can bend the end of plate without hammering and reducing flat part of plate after bend. FEATURES Heavy rigid base frame structure with foundation support Fabricated M.S. body Double reduction and triple reduction of gear for reducing r.p.m Chrome finished Tommy bar Motorised banding plate by fitted extra gear motor Plate end bending without hammering High grade cast iron main nut and bushing Die end for section profile (optional) Proper cambered & supporting guide rollers for more accurate bending