gyro rotary screen

Get Price Quote

gyro screen working benevolently in the industry, we are the top most manufacturer and exporter of the gyro screen. the screens work on the principle of gyratory motion operated through vibratory motors. the offered screen is manufactured in such a manner that is ensure 100% rotary motion and further, cause stratification and dispersion stirring of material to be shifted. the entire stock of gyro screen find wide application in the industries of food, agro,metal, oil,pharma,chemical and paint. we make sure to design these screens with a special and heavy duty motor that has out of balance weight at the top & bottom. available in different specifications, these screens are offered to our clients at the reasonable prices. features give greater capacity per meter square of screening area no screen choking blinding screen change flexibility further detail gives greater capacity per meter square of screening area read more at: http:www.jasenterprise.comvibro-screen.html copyright © jasenterprise.com read more at: http:www.jasenterprise.comvibro-screen.html copyright © jasenterprise.com we offer a high quality range of this gyro rotary screen which are highly used in solid-solid separation, solid classification or solid liquid separation which also helps to screen the dry powder or wet medium. our offered range of this machine consists of a circular table, which is an assembly of the number of decks with screens and a spacing frame equipped with discharge spout, which is produced by rigid screening devices. gyro screen is made using advanced technology that has three components of mechanical vibration like horizontal, vertical and circular which gives an edge over conventional screen. technical specifications: price of machine ms ss 304 306 and ms base :

Rotary Screen

Get Price Quote

Techno Power engineering is best rotary Screen manufacturers, exporters and suppliers in ahmedabad. The rotary Screen desing and Manufacturing in cylindrical Shape. We offered multiple Cages for Separation of Material as per Client Requirement. The machine has a heavy-duty sharft wich made from EN-8 material fitted with Heavy-Duty bearing at both and. The Screen are making from spring steel materials with MS or S.S grade, as suitable with client Application. The machine desing with top covered and bottom discharge chute for prevent low dusting. The Rotary Screen in Widely Used in Minerals Industries, Agro- Product Industries, Stone Industries, etc.

Best Deals from Rotary Screen

Rotary Drum Screen

Get Price Quote

An innovative, rotary drum type fine bar screen for sewage and effluent treatment plants.APPLICATIONIs the most advanced fine rotary drum screen now available in India. Screens are highly recommended as primary screening equipment in municipal sewage treatment plant and effluent treatment plants of various industries like Food processing, Rayon and textiles, Paper and pulp, Pharmaceuticals, Tanneries, Slaughter houses and so on. WORKING Is installed at an inclination of 35° with the horizontal in to the channel of treatment plant. The wastewater flows in to the open end of the wedge wire drum. While the filtered wastewater comes out from the sides of the drum passing though the wedge wire, the solids of the size more than the bar spacing are retained on the surface of the drum itself. Owing to the blockage by the retained solids, the water level increases on the upstream of the screen. When the water level reaches to the pre-determined level, by virtue of the signal transmitted to the drive, the raking arm mounted on the drive shaft starts rotating. The comb mounted on the raking arm sweeps the drum and deposits the solids on to the collection trough at the center of the drum. The high-pressure water jet assists the deposition. From the trough the solids are conveyed to the washing and compaction zone where high-pressure water jet washes the solids and removes the soluble component. The water used for washing containing soluble components is sent back to the wastewater stream though the pipe.The washed solids free of faces are dewatered by squeezing in the compaction zone before the solids are finally discharged in the container or on to the belt conveyor from the discharge point.SLOT WIDTH : Slot width range from 1 to 6 mm. MATERIAL OF CONSTRUCTION To prevent from corrosion and to provide longer life fine screens are completely made from stainless steel AISI 304 grade as standard. Other grades of stainless steels are available up on request. ADVANTAGES. Rugged mechanical construction - Very long life.. Compact design-Low space requirement. Inclined at 35 Deg- Increased operational efficiency.. Completely made of stainless steel- Very long life. Higher capture rate - Ability to handle diverse waste. Self cleaning- No entrapment of solids.. Minimum moving parts-Lower wear and tear, minimum maintenance, Long life. Simple installation and operation... Factory assembled and movement tested- Faster erection.. Usage of V- wedge wire- Efficient removal of waste, low head loss. In built washing and compaction-Very hygienic and reduced weight of waste

Rotary Screen

Get Price Quote

Rotery screen constructed out of perforated plate alongwith center shaft supported on heavy bearings, drive through crown and pinion gear covered at top with discharge chute.Coolers also have a rotating shell but they are of smaller size does not require refractories since they are being used to cool the material; usually the material is received from Rotary Kiln for cooling. Mostly air is being used, and sometime water is also being spread on shell keep the shell cool.

nickel rotary screen

Get Price Quote

We will accomplish this goal by : Developing long-term relationships with our customers. Providing super quality product at competitive prices. Exceeding industry standards with exceptional customer and technical service. Maintaining our competitive position through leading edge technology. Quality Of Delta Screen / Penta Screen Get Positive Comment From Customers Worldwide, Featured With : Uniform open area, better paste, penetration High ductility, higher printing speed Sharp result with high viscosity Lower squeegee pressure Enhance the adhesion of photo emulsion Cost-saving & reliable

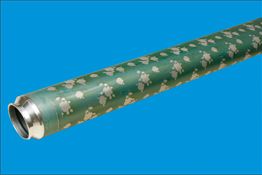

nickel rotary screen

Get Price Quote

Our Rotary Nickel Screen mesh ranges from 25mesh to 165mesh, and length from 1000mm to 3800mm. We provide repeat 640mm, 820mm, 914mm, 1018mm which are of, high quality and can replace the similar products as well from Europe. All other specifications could be customized. Our company pays great attention to product quality, our quality control department inspects every piece of Rotary Screen for the surface appearance, thickness, circumference, open area, and makes sure of no exceeded block holes. It all began ad our dream – to redefine the standards in INDIA for printing screen industry. With all the knowledge and the experience as a guiding beacon, we have moved ahead with steady strides and constant zeal to become one the renowned company in INDIA. Our fully modern equipments along with very hardworking, capable and qualified team, has enabled us to achieve high standards and prestige in the Rotary Printing Screen industry. The well-deserved success of ROOPA SCREEN PVT. LTD. Lies in the philosophy of quality as it is the utmost both for customer and us. The commitment and dedication to achieve this philosophy has resulted in satisfying all our customers. For the past years, we have served hundreds of customers worldwide. Finally, we want to convey that our motto of satisfaction to both the customers and the employees has made us reach the place where we are today. Thanking and looking forward to hear from you soon and assuring our best services at all the times. ROOPA SCREEN PVT. LTD. Is committed to operate a successful business by developing. Manufacturing marketing and supporting quality Rotary Printing Screens for the world textile printing industry. We will accomplish this goal by: Developing long-term relationships with our customers. Providing super quality product at competitive prices. Exceeding industry standards with exceptional customer and technical service. Maintaining our competitive position through leading edge technology. Uniform open area, better paste, penetration High ductility, higher printing speed Sharp result with high viscosity Lower squeegee pressure Enhance the adhesion of photo emulsion Cost-saving & reliable Standard Screens are the reliable choice for the basic designs, features with big holes and strong dams, which is favorable for the penetration of dyestuff. Standard Screens are normally used for coarse substrates, blotches, deeper penetration, gold and bronze prints.

Rotary Screen

Get Price Quote

We FR Engimech Private Limited provide our clients with Rotating Screens, which are specially developed for efficient and economical removing of striped solids. Higher flow capacities can be used due to continuous and self-cleaning effect of the Rotating Screens. Reckoned for low operational costs, these precisely engineered Rotating Screens are sturdy.

nickel rotary screens

Get Price Quote

nickel rotary screens, Rotary Screen End Rings, Flat Bed Printing Chemicals