Self cleaning screen changer

Get Price Quote

We are manufacturing screen changer for plastic processing plant . This screen changer is suitable tor pet processing , box strapping plant, monofilament plant. Tape plant.

Continous Screen Changer

Get Price Quote

Screen Changer in Operation : All Valve are opened with both lines on running position. Close Valve 1 & 2 slowly and remove the plunger by puller and replace the mesh. The plunger placed in body by puller and tightened both of the plunger than open Valve no. 1 as marked so empty chamber of plunger will fill up the material without disturbing the flow. Then open Valve C for removing inside air and clean the material should come out from this Valve and open Valve No. 1 fully. And open Valve No.2 for output than close Valve C. This is again same 2 line working condition. Accessories : Adaptors for mounting the screen changer i.e. die & barrel side. Spares – Heaters, Screen packs. Application & Usage : Necessary to use screen changer for filtering the plastic material. Leak free design. Filter mesh change without stopping the extruder machine. Final product will be consistently good. 100% production without stopping plant. Advantages : Max. exploration of line due to without stop the plant. Elimination of scrap. Very easy operation. No. wastage of material.

Best Deals from Screen Changer

Hydraulic Plate Screen Changer

100,000 - 300,000 Per Piece

Avail from us the Hydraulic Plate Screen Changers in plenty of models, at astoundingly low prices. Used in wide range of applications in extruding plants, these Hydraulic Plate Screen Changers assure durability, advanced design, hassle-free use, quick filter change and other valuable features. Feel free to place desired quantity orders with us. We are the significant Supplier of the Hydraulic Plate Screen Changer from Gujarat.More About Hydraulic Plate Screen Changer : There is less effect on extrusion work when using Hydraulic Plate Screen Changer to filter change. It can be applied to most plastic or rubber extrusion work. Normally rapidity of changing from 4 to 5 seconds per times, depending on the size of the filter The distance between screw and breaker plate can stay 10 mm recently, thereby reducing the possibility of polymer degradation. The screw can pulled out through the screen changer after removed the breaker plate, suitable for single extrusion and co-extrusion production line. Model : 90,100,120,180,200,225,250 Output : 90 to 450 KGSHR Heating : 1 to 8 KW Special Features : Round breaker plate design with maximum melt filtering area Melt filter cavity as per client requirement Leakage proof screen changer due to close clearance tolerances Imported sealing design in input & output melt flow path Smooth operating for changing filters from one station to another thru hydraulic power pack station Melt temperature measuring provision Melt pressure measuring provision for safe & in time operation Advantages : Simple & quick operation 2.simple & quick filter changing 3. Low heating load consumption Saving labour 5. Low maintenance cost 6. Low wastage of material Application : Suitable for variety macroviscosity melt of extrusion line. Including sheet extrusion, extrusion coating, profile tube extrusion, compounding extrusion, cable extrusion, flexible pipe extrusion, lab extrusion, eva, thermosol etc.

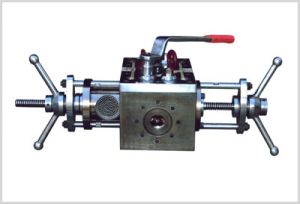

Manual Screen Changer

Get Price Quote

Contamination of the melt steam by metal, wood, paper or internally generated black specks yields products that are unacceptable in appearance and/or performance. Manual screen changers are the least expensive and most suitable option for processes that require infrequent changes. AAROHI ENTERPRISE manual screen changers minimize costly downtime for screen replacement. With a simple swing of the handle lever during routine shutdown, clean screens are quickly brought on-line. No line disconnection occurs, and full production is re-established. As an option the AEP models add air assist to the shifting of the slide plate. Features: 3 position handle 10,000 PSI (690 BAR) maximum head pressure 3,000 PSI (207 BAR) maximum differential pressure Pressure activated seal technology Extruder screw pull through Bolt-through extruder connection Leak free processing AAROHI ENTERPRISE provides full time, total suppport Options: High temperature seal Corrosion resistant flow bores Twist lock co-extrusion breaker plates Downstream reducer bushing AEP air assisted Adaptors Add a melt pump for complete system control

hydraulic screen changers

Get Price Quote

The Hydraulic Screen Changers manufactured, exported and supplied by us are suitable for reprocess kind of extrusions like RP Plants, Filler and Master batch Plants, Compounding Plants etc. where highly contaminated kind of materials are processed. These are highly demanded by our clients and are provided by us at market leading prices within the stipulated time period. Features : Steel body for long lifeLeakage frees performanceBuilt-in heaters give fast heating and retaining superior temperature Comes with energy efficient and most power full Power PackHole-to-hole screen changing can be quickly accomplished without wasting productionCompact, operator friendly & easy to install with low maintenance and low cost spare partsEnsures Quality processing, high product quality and reduced waste materialsThe special chrome and nickel plating gives high protection against wear & tear

Screen Changer

Get Price Quote

Screen Changer, twin hole barrel, Twin Conical Screw, Single Hole Barrel

lever screen changer

Get Price Quote

lever screen changer, manual platen screen changer

Screen Changer

Get Price Quote

Screen Changer, Reduction Gears, Die for Plastic Processing Machinery

screen changers in different pattern

Get Price Quote

screen changers in different pattern

Plate Type Screen Changers

Get Price Quote

Plate Type Screen Changers, Breaker Plates

Die Screen Changer

Get Price Quote

Die Screen Changer, Single Screw

Manual Screen Changer

Get Price Quote

Manual Screen Changer, Screen Changer

Screen Changer

Get Price Quote

Screen Changer, extrusion die, Maintenance Free Edge Trim Grinding System