Non Contact Linear Magnetostrictive Position Sensor

12,970 - 45,680 Per Piece

1 Piece (MOQ)

Non Contact Linear Magnetostrictive Position Sensor • Non-contact measurement, never wear • Absolute position output without zeroing • Nonlinearity, ±0.01%F.S of full scale • Repeatability, ±0.001%F.S of full scale • Compact, oil and dirt resistant • Built-in hydraulic cylinder, flange mounted Features 1.The sensor housing can be rotated 360 degrees for easy electrical connection 2. The electronic head and sensing rod can be replaced without depressurization 3. Fully enclosed electronic warehouse, strong anti-interference ability 4. Non-contact measurement, never wear 5. Absolute output, no need to zero Application ·Plastics machinery ·Fluid Power & Linear Actuators ·Hydraulics and Pneumatics ·Processing machines ·Cylinder displacement measurement

Differential Pressure Transducers

10,000 - 1,000,000 Per Piece

10 Piece (MOQ)

Differential pressure transducers, while similar to standard pressure transmitters, focus on measuring the difference in pressure between two points in a fluid or gas system. They don't provide absolute pressure readings but rather the variation between two pressures. Here's a breakdown of their typical specifications: General Specifications · Differential Pressure Range: This specifies the range of pressure difference the transducer can measure (e.g., ±100 Pa, -10 to +10 bar). · Accuracy: Expressed as a percentage of full scale (%FS) similar to standard transmitters. Typical accuracy for good quality models is ±0.5%FS to ±2%FS. · Output Signal: The most common output signal is a 4-20mA current loop, but 0-5V or 0-10V voltage outputs can also be found. · Supply Voltage: The voltage required to power the transducer (typically 24VDC). · Performance Specifications · Temperature Limits: The operating temperature range the transducer can withstand. · Static Pressure Rating: The maximum pressure each individual input port can handle without damage (important because differential transducers have two pressure inputs). This can be higher than the differential pressure range. · Proof Pressure: The maximum overall pressure the transducer can withstand without permanent damage (typically 1.5 to 2 times the upper limit of the differential pressure range). · Burst Pressure: The pressure that will cause catastrophic failure (typically 4 times the upper limit of the differential pressure range). · Response Time: The time it takes for the output to respond to a change in pressure difference (usually in milliseconds). Environmental Specifications · Ingress Protection (IP rating): Similar to other transmitters, this rating indicates the level of protection against dust and water ingress (e.g., IP65 for dust tight and water jets). · Material of Construction: The materials used in wetted parts (those coming into contact with the process fluid) are crucial. Common materials include stainless steel, Hastelloy C, and Monel. Additional Features · Media Compatibility: The type of fluids or gases the transducer is compatible with, considering factors like corrosiveness. · Communication Protocol (Optional): Some advanced models offer communication protocols like HART for remote configuration and diagnostics. · Display (Optional): Some transducers may have a built-in display for local pressure difference reading. · Calibration: Calibration is necessary to ensure accuracy. Some models offer features like zero and span adjustments for easier calibration. Factors to Consider When Selecting a Differential Pressure Transducer · Process Connections: The type of fitting used for connecting the transducer to the two pressure points (e.g., NPT, flange). · Electrical Connections: The type of electrical connector for power and output signal. · Fluid Compatibility: Ensure the materials and media compatibility specifications match the fluids in your application. By understanding these differential pressure transducer specifications and additional factors, you can select a suitable model for your specific application that requires measuring pressure differences in liquids or gases.

Best Deals from Sensor Transducer

Voltage Measure Transducers

7,000 Per Piece

TTS TORQUE TRANSDUCER

Get Price Quote

This is used in industrial and research applications where torque is to be measured accurately. It is easily fitted to the test batch with the help of suitable A-key way. Flange mounted version available. Dimensional variations can be designed on request to suit customer's specific requirements and applications. Suitable for clock wise and anti-clock wise directions.price of capacity upto 500kg

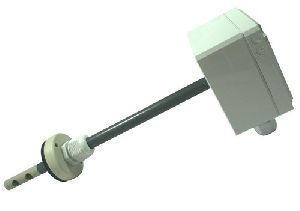

Air Velocity Transducer

4,500 Per Units

1 Units (MOQ)

-1661069235-6500851.jpeg)

linear transducers (Scale)

2,000 - 15,000 Per NOS

1 NOS (MOQ)

Linear Potentiometers RTL & LPH Series Measuring Range 30 ~ 1000mm Long mechanical life 100 million cycles Excellent repeatability < 0.01 mm Infinite resolution RTL (5 kOhm : 30….600 mm or 10 kOhm : 650….1000mm) LPH (5 kOhm : 30….600 mm or 10 kOhm : 650….1000mm 20kOhm : 1250….2000mm)

SECURE METER FREQUENCY TRANSDUCERS

Get Price Quote

SECURE Frequency Transducers offers accurate true RMS measurements. Upto for load independent galvanically isolated analog ouptputs can be configured for desired input range. Theses transducers comply with IEC60688.

voltage transducer

2,450 Per Piece

AC / DC Voltage Transducer

Get Price Quote

FEATURES => Stability and High Accuracy Output=> External Span & Zero adjustment=> Low Internal consumption=> Compact size=> Optional : multiple Output

Submersible Pressure Transducers

5,000 Per Piece

10 Piece (MOQ)

Pressure Transducer

4,800 Per Ounce

digital pressure transducer

Get Price Quote

digital pressure transducer, Digital Liquid Level Controller

Ultrasonic Immersible Transducers

Get Price Quote

Ultrasonic Immersible Transducers, Ultrasonic Cleaner for Inkjet Printer Head

Air Velocity Transducer

Get Price Quote

Air Velocity Transducer, Digital Dial Indicator, Lux Meter

Pressure Transducers

Get Price Quote

Pressure Transducers, Construction Machinery, weighing pads

Pressure Transducer

Get Price Quote

Pressure Transducer, Pressure Transmitter, Electrical Tester

Setra Model 264 Differential Pressure Transducer

Get Price Quote

Setra Model 264 Differential Pressure Transducer

Pressure Transducer For Industrial Application

Get Price Quote

Pressure Transducer For Industrial Application, Festo Rodless Cylinders

linear transducer

Get Price Quote

linear transducer, High Performance Injection Molding Machine Controller