Semi Automatic Solid Liquid Separator

450,000 Per Unit

1 Unit (MOQ)

Oil Water Separator

Get Price Quote

Supported by superior transportation system, we can easily make safe and quick deliveries within the promised time span. We are a noteworthy name, engaged in offering qualitative lot of products that are the perfect outcome of premium material and modern work methods. Also, the material is sourced from the trusted places after complete quality checking.

Best Deals from Separation Equipment

Vibro Sifter

Get Price Quote

Salient Features Stainless steel GMP construction with S.S. 316 contact parts Fitted with Vibro Motor Provided lid for dust free operation Easy to clean and movable machine. Provided sieve with silicon sealing Low operating and maintenance cost. Long screen life. Easy for assembly & de-assembly for cleaning & change over of screens. Springs amplify the vibrations leading to reduced motor HP, maintenance & operational cost. Available in 20" dia, 30" dia, 48" dia., 60" dia size sieve model Process Operation This vibrating energy screen is unit consisting of circular pre-tensioned screen mounted on the frame along with vibrating motor. The vibrating motor imparts three plane vibrations to the screen due to revolving eccentric weights. Total assembly is mounted on suitable springs so that it becomes a independent body which vibrates without parting any vibrations to the foundations.

Vibro Separator

Get Price Quote

The leading manufacturers of Vibro Separator across the country. Basically, a vibro separator is used for grain cleaning in the milling of wheat, durum wheat, corn, rye, oats spelled and rice as well as in storage elevator. Our vibro separators are known for their high performance.

Rare Earth Liquid Line Separator

Get Price Quote

SHREENATH 'T-Trap Magnetic' Separators are designed for heavy duty large volume liquid and semi-liquid line flow system. The T - Trap employs a slip in cage of stainless steel permanent m magnet tubes. The function of the magnet tubes is such that the captured tramp metal particles migrate to the rear of the tubes where they remain protected from wash-off until the tubes are cleaned. The magnet cage has positioning lugs that mate with locating recesses in the body of the tramp. Having a top access bolt on steel plate and seal, the T-Tramp is easy to clean. With the top removed the magnet cage is simply lifted out, Wiped clean and reinstalled. Available in 7 standard line sizes from 2 to 18 inches in diameter, T-Traps can also be produced to meet special applications.

24 Inch SS Vibro Sifter

52,000 Per Piece

1 Piece (MOQ)

Pharma Vibro Sifter

50,000 Per Piece

1 Piece (MOQ)

VSM36 Vibro Sifter Machine

80,000 Per Piece

1 Piece (MOQ)

Confider Industries stands as a beacon of excellence in the realm of food processing machinery, offering an extensive array of products tailored for both domestic and commercial applications. With a diverse portfolio comprising over 90 meticulously crafted machines, our company epitomizes innovation, reliability, and superior quality. From humble beginnings, we have grown into a globally recognized brand, catering to the needs of customers worldwide. At the heart of our success lies a relentless commitment to delivering top-notch products that exceed expectations. Every machine manufactured by Confider Industries undergoes rigorous quality control measures, ensuring precision engineering and durability. Whether it's a small-scale operation in a home kitchen or a large-scale industrial setting, our machines are designed to meet the diverse demands of modern food processing. One of the hallmarks of Confider Industries is our unwavering dedication to customer satisfaction. We understand that purchasing a food processing machine is an investment, and thus, we go above and beyond to provide unparalleled after-sales support. Our team of experts is readily available to assist customers through calls and video calls, offering guidance, troubleshooting, and technical assistance whenever needed. We believe in building long-lasting relationships with our customers, and our commitment to after-sales service reflects this ethos. Furthermore, Confider Industries takes pride in its global reach. With an extensive network of distributors and partners, our machines are delivered to customers across continents. Whether it's a bustling city in Asia, a remote village in Africa, or a thriving metropolis in Europe, our products have found their way into kitchens and food processing facilities worldwide. This global presence underscores our reputation as a trusted provider of food processing solutions on a global scale. Innovation is at the core of everything we do at Confider Industries. We continuously invest in research and development to stay ahead of market trends and technological advancements. Our team of engineers and designers work tirelessly to develop cutting-edge solutions that streamline processes, enhance efficiency, and elevate the overall user experience. From state-of-the-art automation technologies to eco-friendly designs, we strive to push the boundaries of innovation in the food processing industry. Sustainability is also a key focus for Confider Industries. We recognize our responsibility to minimize our environmental footprint and embrace sustainable practices throughout our operations. From sourcing materials responsibly to optimizing energy efficiency in our manufacturing processes, we are committed to fostering a more sustainable future for generations to come. In conclusion, Confider Industries stands as a beacon of excellence in the food processing industry, offering a diverse range of high-quality machines for domestic and commercial use. With over 90 machines in our portfolio, a global presence, and a steadfast commitment to customer satisfaction, we continue to set the standard for innovation, reliability, and excellence in food processing.

Vibro Sifter Machine

Get Price Quote

1 Piece (MOQ)

Garlic Bulb Separating Machine

Get Price Quote

The Garlic Bulb Separating Machine, provided by us, is reckoned for its make & durability. We believe in keeping transparency in the transactions and thus we offer an invoice to the clients stating all the necessary details. We undertake both online and offline payment processing methods. One can stay assured for high quality of the offered lot as we design and develop it using the best in line raw material and modern work methods. In addition to this, we make sure that the material is sourced from the trusted places only.

belt oil skimmer

Get Price Quote

Belt Oil Skimmers remove tramp oils from coolant tanks, CNC machines, part washers etc. Light weight non-corroding aluminium die cast construction Magnet on the base permits installation on any metal base Compact design fits on almost all CNC machines & also on a 2" dia. bung hole on 205 litre drums Built-in oil decanter/separator - the decanter collects oil & coolant picked up by the skimmer & separates it through the mechanism of gravity OIl is sent to a disposal container & coolant back to the coolant tank - saving about 90% of the coolant

Vibro Sifter

Get Price Quote

Vibro Separators are circular unitary gyratory screens used to separate mass composition of solids from solids, and for gradation of materials as per particle size, having wide range applications. The structuring of the machine has been designed in order to achieve the multiple plane vibration by suitable assembly of the specially designed Vibratory motor (constructed for this purpose) having eccentric weight at the top and bottom ends of the motor shaft. The motor is mounted vertically at the centre of the screening assembly, on a circular base by means of springs which allow the Unit to vibrate freely. The springs absorb the vibrations and prevent them to be transmitted on the floor. The top weight causes vibration in the horizontal plane which causes the material to move across the screen towards the Periphery. The lower weight acts to tilt the machine which causes vibration in the vertical tangential axis. The angle of lead of the lower weight with relation to the upper weight provides variable control of the screening pattern. Thus the material moves across the screen and also in the vertical and tangential planes enabling maximum screening.

Portable Vibro Sifter

50,000 - 200,000 Per Piece

1 Piece(s) (MOQ)

Salient Features : Noiseless, Maintenance free & high speeds Available in various models providing screening diameter of 12”, 20”, 24”, 30” , 36”, 48” etc Portable and compact Electric power requirement less than other machine of the kind in the industries & lower energy Consumption compared to reciprocating vibratory system Standard machine are with TEFC motor explosion proof / flame proof motor material. Special requirement like brushing arrangements, SS lid with charging port and spring loaded outlets Easy dismantling and cleaning facility for contact parts Double & Triple deck screens with outlet and hopper for bottom deck available on request

Vibro Sifter

Get Price Quote

Our organization is one of the most reputed and efficient manufacturer and exporter of Vibro Sifter in Ahmedabad, Gujarat. A team of trained professionals verify the product. It is manufactured by making use of high grade components and growing technology. Vibro sifter finds application in pharmaceutical and chemical laboratories as it has a high degree of surface finishing. Checking arrangements are available with the product and faster output is ensured at low power consumption. Also, assembling and cleaning of the product is free from complications. Features : Double deck arrangement can be provided Faster output at low power consumption High Degree of surface finish All contact parts made of SS 316 as per GMP standard Easy dismantling and cleaning Unit Consists Of : Specially designed vibratory motor to run on 400/440 V, 3 phase, 50 cycles electric supply with adjustable eccentric weight at the center of the base plate of screening Screening unit consists of SS 304 / 316 screen sandwiched between SS 304 / 316 hopper and bowl with help of special clamp with gasket. This in turn is clamped to the base plate Option Available : Multi Deck screening GMP unit with SS 304 machine body base instead of MS Dust cover or lid for hopper assembly SS 316 contact parts Castor wheels for mobile unit Sample Availability: Yes Supplier Product Code : HE / 014

Air Classifier

Get Price Quote

We are instrumental in manufacturing and supplying Air Classifier. The offered instrument is used for separating different sizes of particles from two and more kinds of powdered substances. It makes use of centrifugal force and air currents for separation on the basis of weight of the particles. This machine is built in adherence to the industrial standards.

Vibro Separator

Get Price Quote

Salient Features Flour and semolina mills Feed mills Seed cleaning plants Works on cereals cleaning and calibration centers. Aluminum Industries Sand Material

Vibro Separator

Get Price Quote

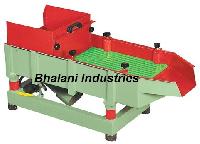

We are offering vibro separator. bhalani vibro separators are dewlapped to separate ceramic media, parts and water by screening. Vibro seprator is powered by foot mounted vibratory motor. This range of vibro separator is known for saving time and labour as compared to the manual screening. These products are known for their sturdiness and reliability. Separation screen will be fitted with nylon perforated for effective separation of ceramics and parts. All the contact parts are mild steel suitably protected against corrosion. The top screen is removable type & can be replaced for screening of different material. features simple construction & maintenance free. accurate separation & easy to operate. can be added in continues production system rugged heavy duty special vibratory motor.

vibro screening machine

50,000 - 90,000 Per Piece

5 Piece(s) (MOQ)

Vibro Sifter

85,000 - 150,000 Per Piece

1 Piece (MOQ)

A vibro sifter machine that is exclusively used in Pharmaceutical & food industries. This sifting machine is manufactured as per the highest standards that meet cGMP norms. The Vibro Sifter machine works on the principle of gyratory vibrations. The material is separated based on its particle size. Once the motor gets energized, vibration is caused in the screen/sieve making the material travel across the sieves according to its particle size. Salient Features Compact and versatile design Sturdy and vibration free design Easy to operate Less maintenance Durable Application Sifter Industry Pharmaceuticals FMCG Beverages

Vibro Sifter

Get Price Quote

Vibro separators are circular gyratory screens used to separate solids from solids and liquid from solid. Vibro Sifter consists of Specially Designed Motor mounted vertically at the center of the base plate of the Screen. The Screen is in between feeding hopper and bowl. The material is fed on to the centre of top screen. The undersize material passes rapidly through the screen during its travel to the periphery. The over size material get continuously discharged through a tangential outlet. This is achieved by specially designed Vibratory Motor along with eccentric Top and Bottom Weights. The top weight on the motor shaft rotates in a plane close to the centre of the mass of assembly. Rotation of the top eccentric weights creates vibration in the horizontal plane which causes material to move across the screen cloth to periphery increasing the horizontal throw, causing oversize material to discharge at a faster rate.

Automatic Vibro Sifter

Get Price Quote

VIBRO SIFTER SIZE AVAILABLE IS 12, 24, 30, 36 & 48.

Garlic Separating Machine

Get Price Quote

We are manufacturer wide range of Tomato, Ginger, Garlic Paste Machine that has fully SS body. These have 6 different dais with 3 H.P. 3 phase electric motor. Best known for high efficiency, low maintenance & corrosion resistance, our machines are easy to operate. The automatic garlic peeling machine is designed to peel dry garlic which adopts pneumatic principle. It can automatically peel the shell of the garlic clove without soaking and meanwhile there is no damage to the garlic at all. The peeling rate can reach at 95% In this all type of Indian garlic are suitable in peeling operation with 95% Accuracy garlic peeler machine is new invention in India on our company with fully Indian make machine with export standard quality.

Vibro Sifter Machine

85,000 Per Piece

1 Piece (MOQ)

Coolant Separator

Get Price Quote

We have brilliant logistics network owing to which safe and timely deliveries are guaranteed with us. Following the strict packaging guidelines, we make sure that the range of products we offer are packed sternly to evade loss/damage. By this, we ensure that the products are in safe condition during handling, warehousing and transportation.

Vibro Sifter

Get Price Quote

As we want to maintain transparency in the business dealings, we offer an invoice stating all the necessary details of the payment and also ensure that the transactions should remain safe. In order to maintain high-quality standards in our offerings, we make use of the finest grade raw material. Also, we ensure that the material is sourced from the reliable places only. Features : Faster Separation due to springs Multi-deck models available Same sieve as used in the Mechanical sifter. Lesser Maintenance and Power Consumption than the Conventional Sifter Simple & Compact construction

Vibro Sifter

Get Price Quote

Vibro Sifter

Get Price Quote

We make use of the quality basic material in the production of the entire range. The material is thoroughly checked by our quality experts before procurement from vendors. With us, payment transactions will always remain secured, as we have adopted modern payment procedures that guarantee instant and hassle-free transactions.

Air Separator

Get Price Quote

Moisture Separators

Get Price Quote

when steam/air is passed through the separator, any entrained water droplets are encouraged to separate and drain away rather than remain in suspension. Steam or air flows around a series of baffles and its velocity is reduced because the space in the separator is large compared with the pipe bore. However the inertia of water droplets carries them on in a straight line so they impinge on the baffles and drain away. The baffles are designed to divert separated water from the flow of steam or air. Together with reduced velocity this prevents re-entrainment. water in suspension- your invisible enemy all steam distribution systems contains a certain amount of water due to condensation and carry-over from boiler turbulence and foaming. A similar problem arises with compressed air systems because water is a natural ingredient of atmospheric air. In both cases, careful draining and trapping will remove much of the water but not all. It cannot remove the water particles suspended in the steam or air. All too often nothing is done to remedy this problem. Because the water cannot be seen it is ignored. The consequences can be very costly indeed. the damaging effects of water in steam systems when water droplets reach the point of usage they needlessly increase thickness of the water film on the heat exchange surface. And water is a very poor conductor of heat. In fact, a water film just 1mm thick is as resistant to heat transfer as a half meter thickness of copper. The water may also carry impurities which will be deposited as scale – another barrier to efficient heat transfer. What’s more, traveling at high velocity, the droplets will both erode and corrode valves and valve seat and shorten the life of pipelines and fittings. the damaging effects of water in compressed air systems suspended water droplets cause similar problems. Pipe, valve and fittings will corrode. Particles of corroded metal may be swept along the system, clogging valves, strainers and traps. At the point of usage, water delivered with air can damage work pieces. Air powered tools will require excessive maintenance and will wear prematurely. design features / benefits rex separatiors safeguard your costly equipmentrex separators will protect your costly equipment from harmful effects of water droplets, because they remove water droplets from steam or compressed air system and increase operating profitability by: improving steam quality to maximize heat transfer and therefore plant efficiency. reducing maintenance costs and extending the life of pipelines, valves, traps, strainers and other associated equipment. protecting compressed air tools and preventing water damage to workpieces. dry steam or compressed air for increased efficiency and longer plant life. effectiveness over a wide range of velocities with minimal pressure drop.

Moisture Separator

Get Price Quote

Generally, compressed air is vulnerable to various types of contaminations that greatly reduce its value as a power source and can have a profound effect on the machinery that it operates. Moisture is the most common and the most hazardous contaminant present in the air.Moisture Separatos are used to Separate Moisture From Compressed Air Line Application and can be protect the expensive pneumatic instruments. Features Moisture Separator does not need any maintenance or repairs Compact & easy operation Moisture Separator performs constantly and consistently 99.99% working efficiency Fine adjustment of lubrication 4 to 5 Years Expected Life