Submersible Sewage Pumps

Get Price Quote

10 piece (MOQ)

Sewage submersible pump

Get Price Quote

Best Deals from Sewage Pump

Sludge Slurry Pump

12,000 - 150,000 Per Unit

1 Piece (MOQ)

Submersible Sewage Pump

18,000 - 55,000 Per piece

1 piece (MOQ)

PNS Sewage Submersible Water Pump

Get Price Quote

ApplicationUsed for pumping sewage water, pumping of heavily contaminated fluids from buildings and surface drainage, industrial and process engineering, municipal waste water pumping.Features Single shaft pump with built in float switch in single phase version. Jacketed dry motor Inbuilt thermal motor protection High level of operating reliability Easy to install and simple to use

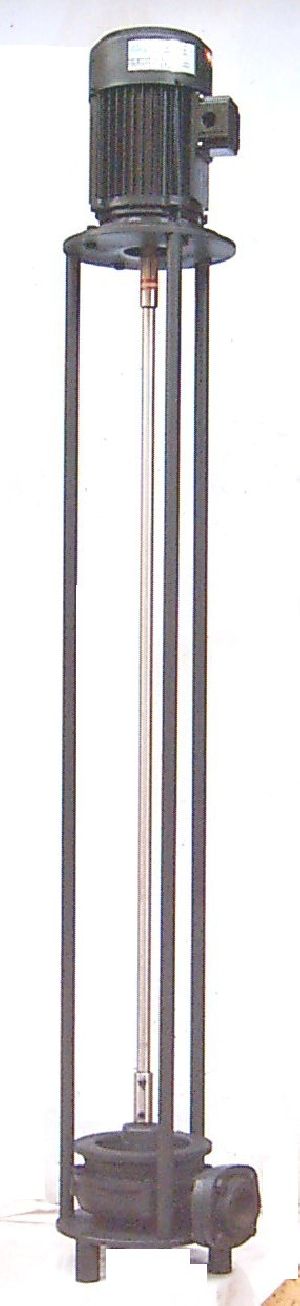

Vertical Sump Pump

Get Price Quote

1 Piece(s) (MOQ)

Vertical Sump Pump can be used in any installation or specially where the saving of space is important factor and most important where liquid is difficult to lift because of nature like temp, corrosiveness etc. These pump are designed for use where the liquid handled to be is of highly corrosive. Nature or where non - adherence of product or zero metallic contamination is must. These pumps are equally ideal for continuous or intermittent service for handling Corrosive as well as ultra pure chemicals without fear of corrosion or contamination. High Temperature services : Maximum working temperature is 110 C / 200 C. Length : Pumps lengths available from 1 to 12 with flow rate up to 50m3/h or 120 meter head. Higher capacities and head available on request and even multistage pump can be also made. Models : Available in conventional or tailor-made configuration. Several models such as suction extension with float switch, duplex pumping station with float switch (auto on/off device) also available. Application Fields : These pumps are in extensive use in the fields of : Pollution Control Filtration Transferring Corrosive Chemicals Slurries Bio gas plants Sewage Waste water treatment plant Phosphoric Acid Plant. H,PO, H2SIFs, H2SO4, HF And Their Mixtures Gas washing plant Scrubbed liquids containing, F,CL,SO2, Ammonia Water treatment plant Any types of acidic water lifting M.S Vertical pump are used for transfer of sulphuric acid 98 %. OLUM, CLOTO, NEPTHA

Sewage Lifting Station

Get Price Quote

BOT SERIES Submersible Sewage Pump

Get Price Quote

applications civil engineering, drainage of subway / tunnel for solid sediment, water treatment of ironworks, mobile use for drainage of public facilities, removal of sludge at harbor / river, other drainage of slurry in industry features 1 dry-type submersible pump overload protector is built-in to protect motor from over-heat and over-load 2 inner cable wires and cable base are upgraded by filling epoxy to raise humidity-resistance 3 motor frame and casing are both made of stainless steel and water -cooling jacket is designed for high efficiency of heat diffusion 4 stainless steel shaft is calibrated by dynamic balance test dual mechanical seal sic / sic are installed and dual oil seals are designed to raise effects of dust-proof 5 impeller and agitator are both made of high chrome alloy steel (hcr) which produces high wear-resistance, impeller is also calibrated by dynamic balance test 6 pump housing and stress eliminating plate are both made of high wear-resisting cast iron for durability, and an innovative design between pump housing bracket and mechanical seal lid to reduce flow stress and last the life of seals longer .

Vertical Slurry Pumps

5,000 Per Piece

We offer vertical slurry pumps. Being a well established-organization, we are engaged in manufacturing, exporting & supplying a distinguished range of vertical sump pumps. Our offered pumps are intricately designed under the vigilance of skilled professionals using quality tested raw material and sophisticated technology in line with the international quality standards. Clients can avail this range in various designs, shapes and sizes at market leading price within given period of time. reliable engineers are expertise in manufacturing of vertical sump pumps, design of pump is sturdy and parts are with long life, manufacturers & exporters vertical sump pumps. submerged vertical centrifugal pump: reliable vertical pumps are centrifugal type of single stage with semi open impellers at bottom. Handling liquids, containing solids, have a tendency to polymerize or crystallize special features: no mechanical seal stuffing box required all the wet parts are in p.p. & teflon construction with stand corrosion & erosion. no foot valve required to lift from negative suction no. Leakages problem just like gland or mechanical seal normal maintenance easy alignment heavy duty bearing bracket. centrifugal, quiet, vibration free in m.s. Or s.s. Pump shaft are en-8 or ss-316 impeller are semi-open type hydraulically balanced by back wanes or in the case of large impeller diameters by balancing holes and ware rings both sides in p.p. Pump shaft are quoted with p.p. Sleeve supported in upper part by heavy ball bearing and in the lower part by a bearing bush and according to the shaft length. They are provided with an intermediate bush specifications: ----- up to 40 mtrs material of construction flow up to 50 m3 hr ------ motor hp 1hp to 20 hp poly propylene, m.s., c.i., s.s. application: chemical industries petrochemicals refineries fert

Heavy Duty Sewage Pump

18,000 Per Piece

Payment for consignments can be carried out through offline or online modes, as per convenience of the clients. We assure you any method that is agreed upon by you and the company will be safe. We are the most promising name when it comes to Heavy Duty Sewage Pump. Features : Long functional life Non-interrupted performance Low operational cost Hydraulic efficiency Long Term Dependability

centrifugal sewage pumps

7,280 - 125,685 Per 1 Nos.

10 Square Meter (MOQ)

non clog pumps

Get Price Quote

Non-clog Sewage pump of close coupled vertical ( mono-block type) construction. "VIRAJ" non clog submersible sewage pump offer simple the most economical and most reliable way of solving the pumping and disposal of sewage containing suspended solids, pumping of raw unscreened sewage and effluent, storm water , sand with water as well as raw and waste water containing large solid objects.. "VIRAJ"S rich experience over several year in the filed of designing and manufacturing of varieties of reliable and efficient pump which need practically no maintenance . These pump compactly designed pump are easy to handle and can be installed permanently with the help of automatic coupling in a small sump form where sewage is to be pumped or can be use portable duty .Being submersible they do not require any other pump house.

Submersible Dewatering Pump

Get Price Quote

The submersible dewatering pump we manufacture and supply is in demand for its robust construction with computer aided design, compact and efficient offering best possible output at minimum power input. We fabricate submersible dewatering pump for continuous operation, where pump house is not required as the suction being placed at the bottom draws water to the lowest level. At the unit special anti corrosive process is carried out to a wetted parts for longer life of the submersible dewatering pump. Rock bottom pires has been fixed for the submersible dewatering pump we market. components of submersible dewatering pump pump is driven by 'f' class insulated / pvc coated oil filled motor suitable for 3 phase, 415v, 50hz a.c. Supplyflow of water is passed between motor body and jacket, keeps winding coolmixed flow impeller is mounted on extended motor shaftmotor is protected from raw water by mechanical seals of adequate size and combination of material as per applicationstator and rotor are vacuum impregnated with heavy duty thermal varnishimpeller and rotor assembly are dynamically balanced for vibration free and noiseless operationthirmister control sensor can be providedavailable with aluminium construction up to 10 hpstationary parts like discharge outlet, by pass, bowl, suction case, housings etc. Are of graded c.i. Castingjackets and motor body are hydraulically testedshaft sis made of s.simpeller shall be ci/bronze/ s.sprotective sleeve made of s.soil cooled lubricated anti-friction heavy duty ball bearing of adequate size placed at top and bottomangular bearing is positioned to take up hydraulic thrustmotor leaves either pvc. Coated wire winding or 'f': class winding. used for dewatering of mines and collieriesstrom waterindustrial waste water

Sewage Pumps

Get Price Quote

We are offering sewage pumps,. Applications where self priming action is required. Industrial: pumping polluted liquid, petroleum product,sewage muddy & storm water, tiles & marbles,effluent plant, chemical/diesel/kerosene/ash water. Marine: pumping water from vessel, docks & ports. Civil construction: dewatering foundations, swimming pools, trenches & pits mobile machinery: cooling tower for marine engine & shovels, dewatering from godowns, basements, multistoreys, shopping malls, etc.

Submersible Dewatering Pump

Get Price Quote

1 Piece (MOQ)

sludge pump

8,000 Per Piece

1 Piece (MOQ)

Pressure Booster Pumps

225,000 Per Piece

Centrifugal Slurry Pump

Get Price Quote

Slurry pumps are used widely throughout the beneficiation section of the mining industry where most plants use wet separation systems. These systems usually move large volumes of slurry through the process. Increased global focus on the environment and energy consumption will certainly generate much wider uses for slurry pumps in years to come.

drainage sewage pumps

20,000 - 250,000 Per piece

->Flow Range: up to 2520 m3/h ->Head Range: up to 57 mtrs. ->Rating (KW): 3.7 – 55.0 kW ->Rated Speed: 2900 rpm

Vertical Long Shaft Sump Pumps

5,000 - 50,000 Per Piece

Submersible Dewatering Pump

25,000 Per

Submersible Sewage Pump

30,000 - 125,000 Per No

sewage vacuum pumps

Get Price Quote

VSP SERIES VERTICAL SUMP PUMP

Get Price Quote

vertical centrifugal process pump can be used in any installation or specially where the saving of space is important factor and most important where liquid is difficult to lift because of nature like temp , corrosiveness etc these pump are designed for use where the liquid handled to be is of highly corrosive nature or where non – adherence of product or zero metallic contamination is must these pumps are equally ideal for continuous or intermittent service for handling corrosive as well as ultra pure chemicals without fear of corrosion or contamination. high temperature services : maximum working temperature is 110 c / 200 c. length : pumps lengths available from 1’ to 12’ with flow rate up to 50m3/h or 120 meter head. Higher capacities and head available on request and even multistage pump can be also made . models : available in conventional or tailor-made configuration. Several models such as suction extension with float switch, duplex pumping station with float switch (auto on/off device) also available. special features • bearing free design for handling abrasives in solutions. • motors are flange mounted single or three phase tefc from 1 hp to 100 hp . • epoxy / polyurethane paints are used on metallic bearing housing. • radial vanes on backside of impeller increase flow or fluids through the sleeve bearing preventing overflow at top of column. • lubrication of bearings by product itself or by fresh water. • all models operate at 1450 rpm / 2900 rpm (variable speed motor available ) • specially designed vapor seal provided to protect bearing from corrosive fumes • dynamically balanced impeller. application fields these pumps are in extensive use in the fields of • pollution control. • filtration . • transferring corrosive chemicals . • slurries . • bio gas plants. • sewage. • waste water treatment plant. • phosphoric acid plant. h,po,h2sifs,h2so4,hf and . their mixtures. • gas washing plant . • scrubbed liquids containing , f,cl,so2,ammonia • water treatment plant . • any types of acidic water lifting . • m.s vertical pump are used for transfer of sulphuric acid 98 %. Olum,cloto,neptha advantages of vertical submerged pump • no mechanical seal or stuffing box required • construction withstand corrosion & erosion • no foot valve required to lift from negative suction • no leakages problem just like gland or mechanical seal • normal maintenance • easy alignment

Self Priming Non Clog Mud Pump

Get Price Quote

Self Priming Non Clog Pump

10,500 Per Piece

01 Piece(s) (MOQ)

Pressure Booster System

Get Price Quote

We are instrumental in offering durable range of Pressure Booster System consisting of pumps, control panel and accumulator with packaged valves providing water throughout the system. This Pressure Booster System is either controlled by Pressure, Flow or Float Switch sensing. The pumps of Pressure Booster System can automatically run until the demand is fulfilled. It comprises of precise controls ensuring that operation of the pump is rotated to provide efficient usage. Our Pressure Booster System has the standby pump that is immediately activated to provide unremitting supply. Pressure Booster System offered by us consists of alarm providing timely alerts to the user with information regarding the status of both the booster sets and system. Features of Pressure Booster System Constant pressure is setPLC Controller to ensure maximum comfortEnergy saving pumpsMinimum Water WastageTimer function for different operationsIn set timings of individual pump, auto changes providedDigital indication for number of pumps, power consumed by pump, voltage taken pump, number of working hours of each pumpEfficientLow operation and maintenance cost Benefits of Pressure Booster System Power savingReduces pump�s running timeRemoves Bulky Over Head TankDry-running protection facilityIn-built time relays ensuring constant & steady operation

Sewage submersible pump

17,500 - 36,500 Per piece

1 piece (MOQ)

Sewage Pump

28,970 - 455,120 Per Piece

1 Piece (MOQ)

Biogas Slurry Feeding Screw Pump

Get Price Quote

If you need to move Biogas slurry at a constant rate, the answer could be to use a positive displacement pump. This type of equipment is able to handle viscous Biogas fluids more efficiently than some other types of pump. The Progressing Cavity Pump can also deal with high dry matter content media (up to 10-12 %). With conventional rotary piston pumps this would not be possible (max. 9 % dry matter content). Despite the strong performance, the pump runs very quietly. We are very satisfied.”