stirrer machine

Get Price Quote

High Speed Stirrer

56,000 Per Piece

1 Piece (MOQ)

Best Deals from Sewage Treatment Equipment

Bar Screen

Get Price Quote

The bar screen starts and stops automatically according to the water level difference between upstream and downstream by means of level sensor or by timer clock. The bar screen includes a screen frame, a bar rack (grid) a back dead plate, a series of chain driven rakes and a drive unit. All bearings and critical parts are above liquid level at all times to facilitate lubrication and improve machine life. The number of rakes de? pends on the screen length and type of effluent. When the screen is started, the 2 chains on the sides pull the rakes towards the top of the screen. When passing in between the bar rack, the rakes collect the screenings waste and lift them to the top where an ejector system pushes the screenings waste into the conveying or compacting system. The bar screen is a mechanical fully automatic screen used for liquid/solid separation in the pre-treatment stage of wastewater treatment plants, pumping station, Sewage treatment plant, etc

INDUSTRIAL STIRRER MACHINE

115,000 Per Unit

1 Unit (MOQ)

High Speed Stirrer

35,000 Per Piece

1 Piece (MOQ)

Rotary Vacuum Evaporator

Get Price Quote

To ensure distribution of orders within undertook period, our organization has an outstanding supply chain system in place. Situated in Ahmedabad(India), the company has carved a niche for itself in the market with its flawless range of products. The avant-grade rotary vacuum evaporator we offer rotates with a speed of 160rpm.

FRP Water Storage Tank

Get Price Quote

Leveraging on our vast industrial experience and knowledge, we bring forth a qualitative range of FRP Water Storage Tanks to our global buyers. We are prominent Manufacturer, Exporter and Supplier of FRP Water Storage Tanks in Gujarat, India. FRP Tanks, offered by us, are available in ample of sizes, grades and other related specifications. Further, we make all the necessary arrangements for urgent and bulk requirements.

Paddle Agitator

25,000 Per Piece

05 Piece (MOQ)

Agitator Stirrer

Get Price Quote

Agitator - Stirrer Dispersing, Suspending, Emulsifying & Homogenizing Technik for Liquid and Paste Application & Process : At PRISM, We design and manufacture a wide range of agitators for liquids and Paste for all process in the pharmaceutical, chemical, food, cosmetics and similar industries. Agitators are provided with different types of agitation components for process such as mixing, blending, dissolution, dispersion, homogenization, reaction, fermentation, oxidation, digestion and emulsification of liquid, paste, ointment, solution, viscous material and solid-liquid. Agitators are designed and adapted to any vessel shape and can be implemented with or without lower support. Different types of blades can be combined depending on the process requirements. The sealing system are designed and adapted depending on the requirement of the various process and start from simple retainers to double mechanical seals. Agitators are available with different type of mounting as per suitability of the process and users requirements. Different types of blades can be combined depending on the process requirements and various conditions including the stirring objective, tank shape, rotating speed, viscosity, mixing blades of different configurations should be applied for different operating objectives. Different mixing blades follow various specifications to design and select the configurations of the blades. The ratio of the blade to the inner diameter of the tank, angular speed of the blade top, viscosity change during mixing process and the range of the flow volume are the factors to be considered. There are various types of blade mixer and can be categorized into axial flow and radial flow according to the flow pattern of the fluid in the tank. The main factors affecting mixing performance are as below and the commonly used configurations are listed for reference: Shape, diameter, sweep back angle and slant angle of the mixer blade Number of layers and the vertical position of the mixer blade where it is installed Rotating speed of the mixer blade Shape, inner volume, number of baffles and outline dimensions of the mixing tank Batch operation or continuous operation. Agitators available with different type of drives and speeds with direct motor and with gear drive as per process requirements. Agitators are suitable for mixing volumes 5 liters to 10,000 liters. Salient Features : Design is cGMP - Current Good Manufacturing Practices compliance. All contact parts AISI 316 & non contact parts AISI 304. Capacity available for volume of 5 liters to 5,000 liters. Available various different type of mixing blade. Available different mounting of stirrer assembly. 1. Wall mounting2. Telescopic Stand3. Top of the vessels / Tanks.4. Bottom of the Vessels / Tanks. Can be provided Variable Speed Drive for stirrer by VFD. Option available for Explosion proof motor and controls panel.

agitating driving unit

Get Price Quote

can mix all types of different viscous liquids. Agitator consists of stirring kettle arm and agitating driving unit. The kettle and stirring arm are made of stainless steel. Agitator is used for stirring, agitating & beating all kinds of liquids, emulsions, suspensions and similar mixtures. The kettle can be supplied with double jacket for cooling and heating by water (optional). The agitator is suitable for screwing on all main drive units.

Propeller agitator

Get Price Quote

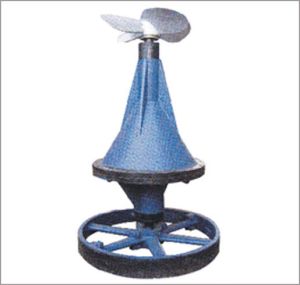

surface aerator

Get Price Quote

We are one of the extensively sought-after Surface Aerator Manufacturers, Suppliers and Exporters in Karnataka, India. We make fixed slow speed Surface Aerators that are designed to work under worst conditions without any problem. Made using advanced production techniques, the Surface Aerator ensures high oxygen transfer capacity. The Aerators impellers are manufactured with a conical surface to ensure maximum flashing of water so that there is maximum oxygen absorption in the waste water and minimum energy consumption. The Surface Aerators can be manufactured both in Mild Steel and Stainless Steel depending on the clients' requirement.Attributes Of Surface Aerator. Robustr. Very efficient. Low initial cost. Low maintenance. Easy to run and maintain

High Speed Stirrer

Get Price Quote

This is for mechanical analysis and also other laboratory applications for stirring Speed approximately 4000 R.P.M. under load. A dispersion cup is supported on a rest on the stand of the stirrer and has a removable baffle. For operation on 230V A.C. supplied with dispersion cup or baffle cup.

Rotary Vaccum Evaporator

Get Price Quote

Introduction: (New improved model with variable system and DC motor to work on 220 volt AC.) The apparatus consists of an evaporating flask rotated by non-sparking electric motor in heating water bath. The drive unit is clamped in V shaped heavy duty stand. The introduction tube permits continuous feed of the liquids into evaporating flask and also distillation under controlled atmosphere. The evaporating flask is pear shaped to give a large surface area for evaporation, clamped to a glass duct which goes through the drive unit and produced into the condenser is fitted with B-19 joint through which introduction tube is inserted. The condenser spherical join S-35 at the bottom of the condenser to receiver flasks cap, 1 litre of corning glass With ball point socket. Complete units is fitted on 'v' shape heavy duty stand with quick jack action. Waterbath and vacuum pump at extra cost.

chemical agitator

Get Price Quote

Manufacturer & Supplier of Chemical Agitators, Chemical Process Agitators, Industrial Agitators, High Speed Agitators, Stainless Steel Agitators, Liquid Mixing Agitators, SS316-304 Agitators etc Engaged in providing superior quality Agitators. These Agitator are good demand in the market due to high quality and durability. These products are available from us in market at competitive rate

High Speed Stirrer

Get Price Quote

This type of machine consist of a motor of reputed make. All contact parts will comprise of S.S 304 material. It will have a protecting cage with two 20 mm bar held apart by closing flat ring clamping on to the bar. The shaft will be coupled directly to the motor shaft. An extra bearing on the coupling sleeve will be provided to reduce the load on the motor bearing. lt will consist of an impeller of special design.Material of construction: SS 304SS 316L MSSS Jacket or limpet coil for steam heating, cooling High Speed Stirrer is used in many industries for stirring purposes for Premixing, Mixing, Dispersing, Shade matching, Homogenizing & Shearing of Liquids.High speed industrial stirrer is used in paint Chemicals, Ink, Food, Milk, Pharmaceutical Industries for thinning the colors. Machine is fully automatic Lifting & Lowering system, Speed control 0 to 3000 RPM, time / batch controller full enclose type casing. Different type of mixing blade can be exchangeable. High Speed Stirrer is offered by us is manufactured using mild steel and stainless steel. This lowers the maintenance problems and makes cleaning very easy. Its steel body makes it corrosion resistance. These high speed stirrer are available in hanging type model. These high speed stirrer are appropriate for mixing. This type of machine consist of a motor of reputed make.All contact parts will comprise of S.S 304 material. It will have a protecting cage with two 20 mm bar held apart by closing flat ring clamping on to the bar. The shaft will be coupled directly to the motor shaft. An extra bearing on the coupling sleeve will be provided to reduce the load on the motor bearing. lt will consist of an impeller of special design. High speed disperser is widely used in the chemical production to blend and mix liquid with solid or liquid with liquid. It is suitable for all the premixing, ready mixing, dissolving. Applicable for Paint, Ink, Pigment, Color paste, paper making, resin, food, beverage...etc

Filter Press Cloth

Get Price Quote

With the aid of our procuring agents, we have been able to bring quality-approved Filter Press Cloth. Products are fabricate by making use of the optimum quality raw material, obtained from the genuine and trusted vendor in the market. These are manufactured using Non Woven and Woven Filter media. Our product is highly appreciated in industries like beverages, chemicals, food and many other.Features:1. Leak proof2. High performance3. High linkage4. Long lasting durability5. Chemical resistive

Agitators

Get Price Quote

Energy efficient agitators find application in all type of Pulp Storage Chests, including Height Density Towers, Mixing Chest & Machine Chest.

Water Filter FRP Fiberglass Pressure Tank/Vessel for Water Treatment

Get Price Quote

We are the main supplier of this product.

Water Flow Meter

1,500 Per Piece

We are the leading supplier of this products.

fluid agitator

Get Price Quote

High Speed Stirrer

Get Price Quote

PVS High-Speed Stirrer (1Hp Single phase to 10 Hp 3phase) Specially design for High speed mixture of chemical.

stp & etp equipments

Get Price Quote

stp & etp equipments, etp plant

FRP DRINKING WATER TANK WITH TERAFIL FILTRATION

Get Price Quote

1 Set(s) (MOQ)

We are pleased to introduce ourselves as ms. Devikrupa electronics dealing in grpfrp terafil drinking water tanks. We are the quality suppliers and manufacturers, we are proud to have zeroed in on ms. W e p l, and are their authorized distributors and representatives. They have great track record of supplying terafil filters to many needy, mostly from governmental institutions, and those who have developed for the first time in the world, solutions based on the type of contamination and problem of water in specific geographical region. They have developed arsenic removal filter without electricity for the first time in the world which has been deployed in larger sizes and volumes across bihar and west bengal. Terafil is a low-cost water filter made of natural materials invented by the council of scientific and industrial research - csir (immt) bhubaneswar, supported by the department of science and technology, government of india. Terafil water filters do not need electricity to function, is affordable and free of maintenance. This makes the cost of purification extremely low cost per tonne of water! affordable and natural, it is highly suited for the poorest districts of india which often do not have access to continuous electricity. Our principals have few patents and national awards to our credit, and winner of power of ideas -ciie programme, and leaders in innovation fellowship from royal academy of engineering awardee. we shall be obliged to give presentation of these projects to your kind selves so that required projects can be implemented to establish in your contry states for good and welfare of entire community.

Agitators

Get Price Quote

Agitators, Automatic Blister Packing Machine, Kettle, Vessel, REACTOR

Anchor Agitator

Get Price Quote

Anchor Agitator, chemical plant machinery, Chemical Condenser

water treatment equipments

Get Price Quote

water treatment equipments, ro plant machine, Jar Filling Machine

chemical agitator

Get Price Quote

chemical agitator, Centrifugal Pumps

water treatment equipments

Get Price Quote

water treatment equipments, Chemical Machinery, Pharmaceutical Machinery

Industrial Stirrer

Get Price Quote

columns, glass blown items, multi neck flasks