Vertical Main Drive - Vmd Plc Touch Screen

Our vertical main drive with plc base automation ,all control system can be operate through touch screen & it features a 1 hp, 230 v, 50 hz, single phase a.c motor connected to sturdy worm reduction gear box is completely maintenance free. Http:www.shaktipharmatech.comhorizontal-vertical-main-drive-plc-automation.html

...more

Universal Gear Coating Pan

The universal gear is a basic requirement for our different attachment like the coating pan, polishing drum, pelletizer, cube mixer, mini ball mill etc. The universal gear required when the operating angles for the above attachments have to be changed. The unit offers an adjustment of the angle of operation from 0 to 60 degrees. This attachment is suitable to attached in our both main drive.

...more

Triple Roller Mill Machine

Triple Roller Mill – STRM is used in the preparation of ointments, salves, dough and similar products. The hourly production is from 2 Kgs. To 12 kgs. depending upon the constituency of the material. Three hard stainless still roller, which are 110 mm long, and 50 mm diameter produce the Rolling action. Two outer rollers are spring supported to eliminate the possibility of damage to the rollers or to the operating mechanism. The space between the rollers is adjustable by turning one thumbscrew. This Attachment is Suitable to Attached in our Both Main Drive.

...more

Tablet Disintegration Unit

Complies to all current USP, EP and other pharmacopoeia, Supports 2 test baskets & Quick release basket design, Compact, user-friendly operation, Connectivity with PC -Compatible keyboard for feeding product information, Selectable type of Disintegration: normal basket suppository basket, Incorporated the Code of Federal Regulations (21 CFR Part 11) feature of password protection (3 level ADMIN, SUPERVISOR and USER Password) Temperature : Ambient to 50°C Accuracy : Better than ±0.3°C

Temperature : Ambient to 50°C

Accuracy : Better Than ±0.3°C

Resolution : 0.1°C.

Power : 230V AC

...more

Tablet Coating Machines

High Efficiency and Intelligent Film and Sugar Coating Technology+ TabsCoat-M Tablet Auto Coater for R & D and pilot Scale manufacturing is designed for the application of Film Coating & Sugar Coating. TabsCoat–M is a product line of compact self-contained laboratory coating system with interchangeable pan

...more

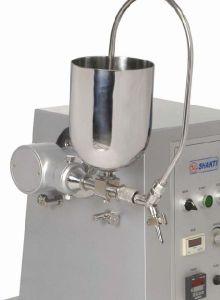

Suppositories AND Lipstick Unit

This apparatus is used for molding suppositories, lipsticks and similar products. This equipment permits melting, agitation and mixing during operation. Stainless steel kettle and agitator are thermostatically heated with 1000 watt heating element. Thermostat permits adjustment of temperature of kettle 80-90 degree C. The stand, below the filler nozzle, holds any type of mould. It is adjustable in all directions and controlled by a hand wheel. Production varies with material, moulds, etc. Stirring, mixing and melting are achieved in a single operation and are not interrupted during the filling process. The pot for filling and molding suppositories and lipsticks are suitable for attach on our Main Drive. Optional– The mould as per the requirement of customer can be designed at extra cost.

Dimensions : 15" x 30" x 25" Inch

Packaging Type : 32" x 23" x 14" Inch

...more

Single Punch Tablet Press Tablet

For the development and small batch production of tablets, SHAKTI developed the Single Punch Tablet Press Mini (GMP) SSP-12 with advanced technologies, This Tablet press machine is widely used for pharmacy, chemical, food, and metallurgy industry. It can press round or irregular tablets from various and odd shaped products. It operates automatically i.e. the tablets are filled, pressed and ejected continuously. As its feature; high precision of filling, low-noise, low-consumption of material, and it works smoothly. The minimum consumption of lab material is just 200gm. It is a good machine for research & development in lab at hospital and plant, used to small-scale production. All components are either covered with hard chrome, or made of stainless steel AISI 316 or acrylic glass.

...more

Pilot Scale Roll Compactor

Pilot scale Roll Compactor is mainly used in R&D facility for the pilot batches. Construction Basically it consists on main structure which is made from steel SS 304 tube and separate instrument panel box. All main drive related assemblies are covered in to main structure. Complete machine is mounting on Castor wheel. Application The new LAB Roll compactor machine is used for dry granulation of pharmaceutical ingredients in pharmaceutical, food as well as chemical industries for densification and granulation of powder. The dry compaction of the powder between two rollers on high pressure for increased bulk density, making granules, dust free processing and reducing packing size.

...more

R And D Coating System with PAN

This is a Portable Self-Contained Laboratory Coating system suitable for sugar or film coating of Tablets, Pallets, and Granules etc. Working Principle The tablet to be coated make continuous complicated orbital motion the closed rotating Drum under the action of a streamline of Baffles. During the motion coating medium automatically sprays according to the technological process and rational technological parameters, at the same time hot filtered air supplied under a negative pressure. The hot air penetrates through the tablets core layers and is discharged from the bottom of the layers, so that the coating medium sprayed on the surface of the tablet cores will dry rapidly and evenly, thus forming a solid and smooth surface film on tablet.

...more

Polishing Drum Consist

The polishing drum consists of felt lined inside of a metal drum suitable for polishing coated tablets. The bottom of the drum is also lined with felt. The polishing drum fits with the Universal Gearing exactly like the coating pan and the cube mixer. The top cover, which locks quickly in to place with closures. The cover is fitted with acrylic sheet, which help the observation of the polishing process while the machine is running. This Attachment is Suitable to Attached in our Both Main Drive

...more

Planetry Mixer Vacuum Jacketed

An ideal mixer for creams, ointments, pastes, and liquids, but also for wetted powders in to water jacketed kettle. The sturdily constructed planetary gear can be equipped with various mixing and kneading attachments, made of stainless steel. Depending upon type of the material to be processed, a dough arm, and a mixing paddle. Any material, which sticks to the walls of the kettle, is scraped continuously by the Teflon scrapper, which is shaped to fit exactly the kettle wall. Therefore, homogeneous mixing results in the shortest time. The vacuum jacketed Planetary Mixer is suitable to attach on our Both Main Drive.

...more

Planetary Mixer Water Jacketed

This mixer is designed to be used as a mixing for pastes, ointments & creams in water-jacketed kettle. It can also be used for wet powders. This mixer is provided with a mixing paddle and Teflon scrapper, which is shaped in such manner so that there is minimum clearance with the mixing kettle. The kettle is also easily removable. This Equipment can be use for heating and cooling purpose by hot & cold water circulation.

...more

Pelletizer Unit

Pelletizer is the unit which is equipped with a tilting and locking device, which is easy to operate. This permits adjustment of the infinitely variable setting of the pan angle, over its whole range. For the cleaning of the sides as well as the bottom of the pan an adjustable scraper is provided. Parts coming in to contact with the material to be processed are made of polished stainless steel. The material to be processed is fed manually, or with a metering device, if a continues is required. The tilted palletizing pan, which rotates in a clockwise direction, is tilted to our motor drive. The material is brought to practically the highest point of the pan and then rolls down in the even scrim, to the lower half of the pan. In accordance with the nature of the material the necessary quantity of liquid to from the pellets is added in certain places. The rolling movement and the addition of moisture cause pellet form. Due to the tilted pan and the movement of the material the larger pellets are carried to the top surface. The size of the pellets can be influenced by the tilting angle of the pan by the amount of liquid added and the method, which it is introduced. As soon as the pan is full the pellets will continuously roll over the edge of the pan. This Attachment is Suitable to Attached in our Both Main Drive.

...more

Moulds for Suppositery Aluminium

We are able to make different types of moulds for suppository Unit as per custemor’s requirements. Aluminum suppository molds produce 2 gm suppositories in a universal shape for rectal or vaginal use. Quick and easy assembly - no tools required. Threaded posts and wingnuts secure the mold in precise alignment.

...more

Manual Tablet Hardness Tester

Salient Features Very compact, simple & Easy to operate. Cost Effective Selectable units of measurement like Kilopond (kp), Newton (N), Pound (lb or lbm), Strong Cobb (SC) Microprocessor based reading of measurement. Easy to calibrate. In-Built Thermal Printer. Statistical Data for the Maximum, Minimum & Mean Values are printed for the Tablet Tested at the End of the Test IQ/OQ Documents

...more

Laboratory Table-top Spheronizer Mixer

A Laboratory Table-top Spheronizer This Equipment used for R & D or Teaching work with small quantities rare and expensive development compounds. Spheronization is widely used within the pharmaceutical and allied industries. Spheroids are small spherical beads or pellets. That is generated in a Spheronizer from extruded material. The diameter of the spheroids is largely determined by the diameter of the Extrudate. You can use spheroids when incompatible active ingredients need to be presented in a single dose or when you require an active ingredient to have different release rates within a single formulation. With spheroids you can have excellent flow and metering properties as well as packing uniformity. With spheronization you can reduce or eliminate dust hazards. Typical spheroid sizes are from 0.8mm to 3.0mm. The Spheronizer has an easy to use operating structure. The front panel has ‘Start’ button, ‘Stop’ and ‘Emergency stop’ button along with indicators for ‘Power on’, ‘Motor on’ and a speed control device that allows changes in disc speed during the spheronization process if required.

Weight : 26.5 kg.

...more

Lab Kneader

Lab Kneader – Inside of the through two Z- shaped stirrers rotate towards each other at different speed. The special shape of the stirrers and the speed differential at which they operate shorten substantially the required mixing time. Stirrers and Bowl are made of stainless steel. The Lab Kneader unit had a capacity of 3 to 4 Liters. The Bowl can be delivered with a double jacket for cooling or heating with water. The Bowl is closed with cover made of acrylic so that the kneading operation can be watched. The Bowl can be tilted for emptying or cleaning. This Attachment is Suitable to Attached in our Both Main Drive.

...more

Lab Cone Mill R AND D MACHINE

SHAKTI High Tech Conical Screen Mill extremely reliable, perfect for even the most demanding of processing requirements in F & D. This Equipment balances performance with simplicity, to provide a solution that guarantees a high output but is easy to operate, clean and maintain. The Cone Mill is suited to dry, wet or fine milling in the pharmaceutical, food, chemical and consumer goods industries. The mill can easily be adapted for use on different products, simply by changing the granulating screen, presenting a cost-effective solution to your size reduction requirement. Read More

...more

Horizontal Main Drive Machine

The Horizontal Main Drive type SHMD-AC is the basic machine of the SHAKTI All-purpose equipment. All our Multi-attachments units can be easily and quickly connected and disconnected to the main drive with the help of two quick locking and unlocking hand knurled knobs & it features a 1 HP, 230 V / 110 V, 50 Hz / 60Hz, Single Phase fitted with A.C DRIVE. The Main motor Drive is equipped with a very efficient & maintenance free gearbox with maximum torque. The speed is variable and can be adjusted infinitely between 5 to 434 RPM working range by an electronic speed control. This is done via an electronic speed controller and the corresponding rpm is displayed digitally. The drive also includes a Digital timer in order to set time-based operations. A separate 15 Amp. Power supply socket provided for attachments require heating system

Dimensions : 24" x 12" x 18 inch

Power Supply : 230 v, 50 Hz, Single Phase 230 v, 60 Hz, Three Phase

...more

Homogenizer Unit

Homogenizer unit is suitable for mixing of different types of liquids like oil in water & water in oil construction up to 30 kgs. / Hour. A piston pump produces homogenization. Materials can be filling to pump from a hopper, having capacity of 1.5 liters. By the forward & backward movement of the piston Homogenization takes place. A vacuum is created during the backstroke of the piston, which sucks the liquid back. During the forward movement of the piston, the liquid is pushed against the tip of the nozzle. This Unit is Suitable to Attached in our Both Main Drive.

...more

Hand Operated Capsule Filling Machine

The 300 holes GMP model manually operated hard gelatin capsule filling machine is the most widely used machine of its kind in the pharmaceutical industries. This machine is small and reliable for small units. Speedy and efficient operations are assured from numerous improvements introduced over many years of its wide and varied application in industry. Optional Accessories:– 100 Capsule Filling Hand Operated Machine– Capsule Loading Machine. Machine built in 4 basic configurations according to capsule size.OO/O orA. O/1/2 orB. 3 / 4 or Output Up To 6000 Capsules / Hour For Capsules of 'oo' To '5' Depending On Formulation & Operator Skill. C. 5 size.

...more

Friability Tester

This instrument is specially to determine the durability of tablets from the time of production to the time use, as its is important to test abrasion and impact hardness of the tablets. The apparatus consist of transparent acrylic drums. The drums are equipped with a plastic blade which carries the tablets along with it up to predetermined height while the drums are rotating and tablets are allowed to slide and let them slide down. The tablets are weight before and after the rubbing in the drum have taken place. The Difference in weight indicates the rate of abrasion.

...more

Fluid Bed Processor PLC Table Top

The SHAKTI Fluid Bed Processor GMP Model offers an effective and efficient method for drying, granulating & coating. It is invented keeping in mind the latest cGMP norms with all contact parts AISI 316 Quality. By using modular construction and simplified design we provide flexible installation. The Machine is vertical type, Electrical controls Auto Mode, Arrangement for spraying an active ingredient on to the carrier bed for top spraying, Explosion proof and suitable for efficient accurate and uniform drying wet granulated pharmaceutical solid powder at lower temperature.

...more

Dust Extractor

SDE-DUST EXTRACTOR (DUST COLECTOR) This Equipment is used for controlling dust generated during tablet compression, tablet de-dusting, granulation and other processes to avoids product cross contamination. Minimizes mechanical strain & excessive wear of tableting machine resulting in minimum machine break downs and punch wears. Stainless steel blower fan is dynamically balanced. Suction Capacity : 150 CFM ±10% Dust Storage Capacity (Ltr) : 20

...moreBe first to Rate

Rate This