MOORING PANAMA CHOCK

Panama Chocks (also referred to as Panama Bows) are used specifically for the guidance of rope mooring lines on board a large ship or vessel.Panama Chocks are designed specifically to guide mooring lines on deck. They act as a guide to feed a line or wire in a particular direction while minimizing chaffing. They are typically welded to the bulwark of a vessel.Intended for heavy duty use, the chocks are manufactured from high quality cast steel. Panama Chocks can be either mounted directly onto or into the hull, can be Deck or bulwark Mounted or alternatively can supplied with a base plate to be bolted to a plinth. which are ready for immediate installation.We offer a wide range of high quality deck chocks which are suitable for most vessel applications. We provides a wide range of Panama Bows specifically for industrial shipping and can be found on merchant vessels, tugs and barges.We offer a wide range of chocks which are deck and bulwark mounted and our range can be supplied as per DIN 81915 or JIS – 2017 and IS:6633 specifications. Our extensive chock range can be supplied with a paint primer or Zinc plated finish.We suggest our Chocks are sold as-cast with no surface paint or only primer to maintain quick, easy and safe weld-ability to the Deck or bulwark of any vessel.

...more

MOORING BUOY SINKER

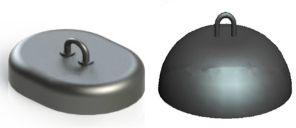

Mooring Buoy Cast Iron Sinkersinkers are adequate to keep buoys in their assigned positions. They do not provide the resistance or holding power of anchors of the same weight but have the great advantage that they will provide the same resistance irrespective of the direction that the mooring load is applied.Sinkers may be made of concrete, cast iron, rock or bundles of used chain.The effective sinker weight will be equal to the weight of the sinker in air minus the weight of the water displacement, that is roughly 66% of Air weight.Rock Sinker can be made by fixing a mooring eye in a piece of rock, or large stone. This may be effective if there is a local supply of dense stone in suitable sizes. However, it is very difficult to assess the condition of an individual rock and it can break in service. Now a days it is an ancient system and no way stable and trustworthy and many accidents occurred due to this type of Sinker.Concrete Sinker are of moderate cost and are manufactured by casting concrete into a suitably shaped mould with a metal eye for attachment of the mooring chain cast in place. However, they are considerably larger than cast iron sinkers of the same submerged weight and thus take up valuable storage space in the depot or on the buoy tender’s deck. Care must be taken in all aspects of their manufacture so that they do not disintegrate or allow the mooring eye to pull out. The quality of the concrete must be carefully monitored to ensure it is of the specified density. But As volume of Concrete Sinker are approx 3 times that of Cast Iron Sinker, It has adverse effect of undercurrent.And self life is very limited so now a days most systems are preferring Cast Iron Sinkers.Cast Iron Sinker is the most durable and effective sinkers are made of cast iron. Their density compared with concrete is approximately in the ratio of 3:1.Cast iron sinkers are robust and the repair or replacement of the mooring eye is possible.If a mooring is prone to sanding in, a cast iron sinker will be easier to extricate than a concrete sinker because its physical size is smaller. Only this type of Sinkers have good scrape value.There are many designs and shapes of cast iron sinkers. We are manufacturing Oval Cast Iron Sinkers and Dome / Semi Circle Cast Iron Sinkers from 200 Kg to 10000 Kg.The two main factors which influence the service life of a mooring system are wear and corrosion These two factors are interactive since the products of corrosion rapidly accelerate wear. Which are very well controlled in case of Cast Iron Sinker. Product Description :1. Type: Sinker2. Material: cast iron3. Shape: oval / Dome4. Dimension: As per standard or Custom Need5. Weight range 200 Kg to 10000 Kg6. Application: mooring system, offshore platform

...more

Mooring Bollard

We are manufacturer of Mooring Bollard since many years. Range of our designs are from 10 MT to 200 MT for all type of bollard listed below and 250 MT for Tee and Twin Horn Bollard.We are in field of Castings and engineering since 1978, and having foundry as well as machine shop under one roof. Machine shop is our advantage to fulfil exact dimensions for foundation and bollard right angle which many supplier don't have, which lead to problem at time of foundation. But in our case we are correcting foundation dimensions which is deviating due to shrinkage of casting.As most of Marine Board and Jetty prefer Bollard with Installation along with required foundation and grouting, we only deal with engineering part and have decided to restrict our role as OEM supply to those who are executing full turnkey work along with other works and civil work execution.In some cases our clients need special or custom designed Bollard, we do the job by developing Pattern and executing it as per custom need. This is mostly required in case of replacement at existing foundation at Jetty.

...more

HEATING PLATEN PLATES

We are the organized manufacturer of Heating Platen Plates for Hydraulic Press.We have good infrastructure with best machinery of era.As now time is changed and generation is changing one should need to work in a new way.We have good know-how of making Press Heating Plates.Our Product is made from material required as per world standard.We are also inspect all the plates by Ultra Test, and all materialogy by sepctrometer as well.By matching exact required QC parameters, will give good Heat Transfer rate, and avoiding early Cracking problems and hence increase self-life of the Platen.Highlights of Product : 1) Raw material is inspect by Ultrasonic,2) Chemical Composition is inspected by Spectrometer.3) All 6 Sides are machined by Milling Cutter Body for Good Surface finish,4) Obstacle free Deep Holes for smooth fluid circulations, and for better thermodynamic properties.5) All side Right angled on Boring Machine for better seats,6) All Platen Fine Grounded if required by customers.7) Each Platen is marked with ID Number and QC report for each plate will be given along with productWe supply Platen as per our clients MOC, and all material testings are conducted by third party NABL approved metal laboratory to get trusted reports. Our Size Range of product is 3000 mm X 2250 mm.

...more

Container Corner Casting

We are the manufacturer of Castings. We have in-house foundry and machine Shop, with wast experience since almost 4 decay. We manufacture Casting Components as per our customers MOC and Drawings.We also have good know-how of manufacturing Container Corner Casting confirming to ISO 1161/IS:7694-1992.In corner casting we are providing as cast and with all six faces machined as per requirements. Weld ability is the critical criteria required in Corner Casting and it is well known to us.As part of technical know how we know the important of CE , along with Physical Properties. Standard parameters of Container corner is as stated below.

...moreBe first to Rate

Rate ThisOpening Hours