tyre reclaim rubber

Tyre reclaim rubber are growing since architects and designers are responding to the exciting new colors and patterns,

...more

Tyre Crumb

Tyre crumb used to describe or measure the size of crumb rubber. Crumb rubber is sized by the mesh screen or sieve through which it passes in the production process. A 30 mesh means there are 30 holes, or openings, per linear inch of screen.

...more

Rubber Tiles

Sunflex standard Rubber tiles has been popular through many years with variety of inherent advantages. We have been engaged in manufacturing rubber safety surfacing from 1989! Sunflex Brand has created its quality trust globally and domestically through many years. Standard Rubber tiles comes in variety of thickness as per customer applications and selection of choice. Sunflex Rubber tiles are environmental friendly. They are SBR rubber tiles made from polymerically bonded with crumb rubber granules with hot mold technology. This are available with variety of eight different standard colours worldwide. We follow the Global standards in recycling process to make better for earth and humans. Standard Rubber tiles are most suitable for commercial gymnasiums and crossfit gym. Commercial gyms are rapidly growing in world it has withstand repeated dropping of heavy weight such as dumbbells. It will absorb the shock of dropped weight without damaging the floor underneath. You must lay this standard rubber tiles with quality adhesive for best result. Great Features Available in 8 different standard colours. Available in variety of thickness. Bevelled edges at side to protect rubber tiles. Heavy Duty commercial grade rubber tiles. Purchase at good economically prices. Price match guarantee.

...more

Rubber Tile Speckles

Sunflex Rubber produce play area rubber tiles for the children play area which is superior solution for playground and path ways. The tiles are manufacture environmentally friendly from crumb rubber granules and premium epdm rubber granules on top surfaces. Sunflex Rubber play area tiles are made in 100% epdm rubber granules which is more hygienic and UV stable in nature. EPDM rubber (ethylene propylene diene monomer (M-class) rubber), a type of synthetic rubber, is an elastomer characterized by a wide range of applications. EPDM rubber flooring is the best quality flooring. It involves epdm rubber granules that are self-pigmented in nature. Hence making it last longer than the SBR variant. And they come in brighter colour shades. SBR flooring is the next best option after EPDM. Its granules are pre-coated with colour and hence the shades available are slightly darker. We have launch 19 different types of sunflex epdm rubber granule tiles with designer series. We have also launch sunflex epdm rubber granules for children play area applications. Sunflex offers 19 colours of EPDM rubber granules with an exceptionally high polymer content for durability in wet pour installations. Design content has been written down to copy and paste in your system. Photograph has been attach in folder of play area rubber tiles.

...more

Rubber Granule

Rubber granule are famous for wet pouring solution in the areas like children play area, swimming pool areas, outdoor areas, jogging track, walk ways.We also manufacture crumb rubber granules as sub floor that can be used for wet pouring.

...more

Rubber Flooring

Rubber flooring has gained popularity because its attractive designs and patterns are compatible with today’s architectural trends without sacrificing performance, sustainability, or cost. More importantly, rubber flooring is durable, contributes to improved indoor air quality (IAQ), and is environmentally friendly.

...more

Rubber Door Mats

Rubber door mats are Entrance Rubber Mats that can be used both indoors and outside. Used outdoors, these rubber mats will not fade, rot or stain due to rain, snow or sun.Effectively removes dirt and moisture.100% recycled rubber floor mat Ideal for heavy-traffic, indooroutdoor areas

...more

Rubber crumbs

Rubber crumbs that has been reduced to a particle size of 38-inch or less. Mesh, or sieve size, is commonly used to describe or measure the size of crumb rubber. Crumb rubber is sized by the mesh screen or sieve through which it passes in the production process.

...more

Reclaimed Rubber

Reclaimed rubber This is because; previously or some years ago, so many people did not see the importance of recycling rubber.is a very simple one especially when the right machinery is used. Machinery used to De-Vulcanised Rubber produces maximum heat that melts and softens the waste rubber which can be used for many products.

...more

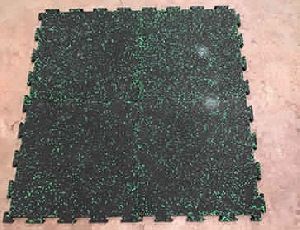

Interlocking Rubber Tiles

Sunflex Interlocking Rubber Tiles are premium quality with its great Interlocking molded technology. Environmentally friendly and fully reversible SunFlex Interlocking Rubber tiles let you create a safe, comfortable, protective floor covering within minutes. Interlocking rubber flooring can be installed easily over nearly any smooth surface including concrete, asphalt, wood or tile. No special tools are required. They are available in puzzle style pieces that fit together securely, like jigsaw. The unique tab design holds the tiles together securely without the need of expensive adhesives, tapes or the fitter to apply them. Installation is as easy as aligning the tabs and pressing together with your fingers or using a rubber mallet. The unique tab design allows for a square or brick installation pattern. These interlocking rubber floor tiles can also be disassembled and reassembled repeatedly without damaging them. Great Features Available in 8 different standard colours. Available in three thickness. Easy to stick rubber tiles on floors. Helps in Reducing the cost of Installation. Heavy Duty commercial grade rubber tiles. Purchase at good economically prices. Price match guarantee.

...more

Epdm Rubber Granules

Sunflex Recycling Pvt ltd manufacture wide range of EPDM rubber granules. As a leading producer in the field of rubber floorings, Sunflex has started the epdm rubber granules with 19 pigments colours available. EPDM "Virgin” rubber granules are the highest quality material made of original rubber compound produced in controlled conditions in order to reach predefined properties. Specially selected components like rubber, oil, pigments and chemical add-ons are carefully blended in the mixer machine. The created compound is then vulcanized in the autoclave to make it hard, but flexible. The last stage of production is to granulate the compound into small, uniform grains with specified size (fraction). HIGH QUALITY – The company has committed to the top most quality by keeping children’s safety in mind by providing them the new VIRGIN + HYGENIC material. RUBBER COMPOUNDING – The compounding of material has been checked with certain stages in the laboratory with good quality satisfactory granules.

...more

crumb rubber granules

Tens of millions tire disposal every year globally. Disposal of waste tire is challenging task because tires have long life and non-biodegradable. The traditional method of waste tire management dumping tires into soil or landfilling are short term vision and investment. To reduce scrap tires worldwide we need to recycle tires to make the solution for waste management. The scrap tires can be recycled by two methods Ambient mechanical grinding and cryogenic method. We use the ambient mechanical grinding method. In ambient mechanical grinding process, the breaking up of a scrap tire happens at or above normal room temperature. Ambient grinding is a multi-step technology and uses whole or pre-treated car or truck tires in the form of shred or chips, or sidewalls or treads. The rubbers, metals and textiles are sequentially separated out. Tires are passed through a shredder, which breaks the tires into chips. The chips are fed into a granulator that breaks them into small pieces while removing steel and fiber in the process. Any remaining steel is removed magnetically and fiber through a combination of shaking screens and wind sifters. Finer rubber particles can be obtained through further grinding in secondary granulators and high-speed rotary mills. Ambient grinding is the production process used by the majority of crumb producers. The machines most commonly used for fine grinding in ambient plants are: Secondary granulators High speed rotary mills Extruders or screw presses Cracker mills Sport Surfaces Kindergarten Playgrounds and Recreation Areas School Sports Areas Athletic Tracks Tennis and Basketball Courts Automotive Industry Bumpers Splash Guards and Fenders Floor Mats for Cars and Trucks Floor Liners for Trucks and Vans Construction Hospital, Industrial, and Bathroom Flooring Floor Tile Foundation Waterproofing Dam, Silo, and Roof Liners Geotechnical/Asphalt Applications Rubberized Asphalt for Roads and Driveways Drainage Pipes Soil Conditioner Porous Irrigation Pipes Road Building and Repair Adhesives and Sealants Adhesives and Sealing Compounds Textured and Non-Slip Paints Roof Coating and Waterproofing Points to be remember We have good tire recycling machineries to produce quality crumb rubber granules. We have monthly production of crumb rubber granules above 500 tonnes. As per past experiences in the field of tire recycling business we have good wealth of knowledge to produce right crumb rubber granules as per your requirement. We also produce black epdm rubber granules for infill turf.

...more

Crumb Rubber

Crumb rubber is defined as rubber that has been reduced to a particle size of 38-inch or less. Mesh, or sieve size, is commonly used to describe or measure the size of crumb rubber. Crumb rubber is sized by the mesh screen or sieve through which it passes in the production process. A 30 mesh means there are 30 holes, or openings, per linear inch of screen.

...moreBe first to Rate

Rate ThisOpening Hours