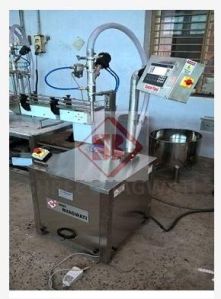

Wine Filling Machine

Our latest designed, advance technology and quality parts and equipments get resulted in most excellent performance of the machines. We can full fill special requirement of the client of filling machines with different specifications. Our Liquor filling machine is faster and apt to handle varied sizes of bottles to fill water. The two basic approaches for filling machines are to control the Fill-Level must be used for wine and the other approach is control the volume. Our Wine Filling Machine provides both approaches. This filling machine prevents the overflow of liquid and control the volume of liquid in container.

...more

Wet Glue Labeling Machine

Shree Bhagwati Machtech (India) Pvt. Ltd. is considered as one of the leading manufacturers and exporters of filling and packaging machineries for various industries in India and across the globe with its head office at Rakhial, Ahmedabad. The organization has earned the reputation of one of the third largest trustworthy companies in India for high quality and reasonably priced machineries that include filling, capping & labeling machines with 4500 Machines installations worldwide.

...more

Water Filling Machine

RFC series machine is a fully automatic multi functional combined machine integrating washing, filling and capping into single body. This machine is equipped with advanced man-machine interfacial control technology with all necessary automations. It works on hanging neck holding method. Hence, very convenient bottle changeover. Versatile machine to pack mineral water as well as other beverages like fruit juice, square etc. which are filled at higher temperature by changing some parts. OPERATION : 1. BOTTLE IN-FEED & RINSER SECTION : The in-feed star wheel has spring loaded neck gripper fingers, which compensates for minor variation in bottle-neck diameter. The bottles fed by air conveyor are picked by fixed size neck star neck and transferred between grip fingers. This eliminates the need of feed worm and change parts for different sizes of bottle body diameter. The neck spider transfers the bottles on to rinsing turret, which has neck gripping fingers to carry the bottle around rinsing. The spray nozzles have No Bottle – No Rinsing spray mechanism, which saves water. The rinsing takes place during 90 degree rotation of turret. Thereafter for next 90 degrees bottles are tilted back by small angle to give adequate draining time. 2. BOTTLE TRANSFER & FILLING SECTION : Duly rinsed and drained bottles are again picked by star wheel and transferred to filling lifter gripper platform. The filling lifters operate on positive cam lift-off principle and do not use compressed air or spring load. Lift cylinder cam is made of stainless steel and machined to fine finish and have simple harmonic motion profile to life bottles smoothly and to fill valve. The filling valve works on gravity filling system but has AIR EXHAUST mechanism, which removes stagnant air from the bottle to outside atmosphere. The top of the filling bowl/tank is fitted pneumatically operated filling valve to single line pipe, which can be piped to outside of the filling room. The filling bowl is fitted with electronic level controller to regulate liquid level in the bowl through pneumatic ON-OFF valve. 3. PLASTIC SCREW CAPPER : There is No Bottle No Cap interlock provided on cap delivery star wheel. The bottles are detected by non-contact infrared sensor to stop the cap delivery. The capping chucks are finest quality precision component fitted with magnetic torque controlling mechanism. This eliminates heat generation which normally occurs in friction type coupling in the chucks. Flexible segmented cap holder picks up the caps. This compensates minor variation in cap diameter occurring due to long storage of caps in the boxes. The capping torque can be set accordingly in minimum of time and set torque in maintained. The capping turret has Pick N Place type cap pick up mechanism, which delivers the cap in the cap holders of capping chucks. 4. CAP ELEVATOR CUM HOPPER : A very specially designed elevator cum selector hopper, which can be provided on selection. The hopper is placed at floor level and can hold up to 5000 caps. Bucket type fingers elevate the caps and right direction caps are allowed to go in to the deliver chute while wrong direction caps are dropped back in the main hopper. The cap delivery chute can be fitted with ozonised water rinse and clean air jet blow to remove water (optional). After that Ultraviolet type of inline cleaning can also be provided on request. The chute has high level and low level infrared sensors. On low-level signal – elevator motor starts and high-level motor stops. The cap rinse water line and clean blow airline has solenoid valves interlocked with main motor. If machine stops – both solenoid valves closes the supply. 5. LUBRICATION SYSTEM : There is central lubrication system, which supplies oil to all vital running components. Manual grease points are placed in convenient locations and grouped together for easy access. APPLICATION : Mainly used for PET bottles mineral water, hot filling of Juice into PET or still water bottling line. For other bottles, contact with our sales representatives. TECHNICAL SPECIFICATION BRAND BHAGWATI Model SBFILL SBRFC-100 Product to be Filled Water Fill Volume 200 to 2000 ml. Output/Min 30-150 depending on fill volume Water Pressure 1500 BPH Rinsing Water Consumption 0.2 ~ 0.25 Mpa Power Consumption 5.03 KW Weight 3500 Kgs

...more

Volumetric Liquid Filling Machine

Automatic Volumetric Liquid Bottle Filling Machine work on volumetric principle with diving nozzles. The unit is made compact, versatile and enclosed in stainless steel elegantly matt finish body, of S.S Slat Conveyor, Reciprocating Nozzle with self-cantering devices & SS Syringe. No container the main drive of the machine and conveyor drive consist of AC Motor with synchronized variable Ac Frequency drive.

...more

Vibro Sifter

Bhagwati Machines India Pvt. Ltd is a leading manufacturer of high speed vibro sifter machine including 20” vibro shifter machine, 30” vibro sifter machine, 48” vibro sifter machine and 60” vibro sifter machines for pharmaceutical tablet press. Vibro shifter has a circular gyratory screen that is used to separate mass composition of solids and liquids according to their grades and particle sizes. Vibration is generated in three different planes along the vertical axis by means of a specially designed vibratory motor that is designed especially to meet various requirement of our clients global wide

...more

Vial Sealing Machine

At Shree Bhagwati Machtech (India) Pvt. Ltd, we strive hard towards offering the best capping machines to our clients. Depending upon your capping requirements, you can select the most appropriate machine from our product inventory that includes Semi Automatic Cap Sealing, Automatic Single Head Vial PP or Flipp-0ff Capping tools, Bottle Screw Capping and Automatic Four Head Bottle ROPP Capping equipment. Our bottle ROPP capping instruments are available with 1, 2, 3, 4, 6, 8 and 12 heads. Other than that, our product inventory also includes Automatic Crew Capping tools with single and multi-heads. Additionally, we offer Automatic and Semi Automatic ROPP Cap Sealing equipment, Automatic Measuring or Dosing Cup Placement devices, Automatic Multi Head ROPP Cap Sealing and Automatic Screw Cap Plastic Cap Sealing device and several other capping machines with diverse specifications.

...more

Vial Labeling Machine

Shree Bhagwati Machtech (India) Pvt. Ltd is one of the leading suppliers of highly functional labelling machinery. With an understanding of specific industry requirements, we offer Automatic Tube Labeller equipment, Fully Automatic Labelling tools with single and double-sided stickers. We also stock a complete range of Fully Automatic High-Speed Wet Glue Labelling instruments, Fully Automatic Self Adhesive Vertical High-Speed Ampoule and Vial Labelling tools, Carton Code Printing Machine, Automatic Bottle Labeler equipment, singledouble side sticker labelling machine, Wet Glue Labeler Machine and Semi Automatic Self-Adhesive Labelling Machine. The vial or phial, as it is also called, is a small bottle especially for liquid medicine. Therefore, the vial sticker labeling machine is normally automatic and can operate at high speed. Automation of the machine reduces machine downtime and increases efficiency. The vial sticker labeling machine has an in-built mechanism that helps to avoid manual feeding and storing of the label length data. Some of the other labelling machines offered by us are Fully Automatic Horizontal Ampoule Sticker (Self-Adhesive) Labelling Machine, Self Adhesive Vial & Bottle Labelling Machine as well as Label Dispensers and applicators.

...more

Vial Filling Machine

Bhagwati tablet counting and filling machine adopts advanced vibration and multi-channel feeder, computer control, dynamic scan counting, transfer the bottle automatically, system test automatically. The machine With Stop automatically function and other advanced technology. This machine designed with GMP standard. Compose the light, electric machinery to one set, which is suitable for tablet or capsule counting and filling in pharmaceutical or food business.

...more

Vacuum Tray Dryer

Salient features construction: external : 2mm thk internal : 2mm thkmoc: cgmpsurface finish : external:buffed to 150 grit matt finish internal: buffed to 220 grit mirror finish.inlet & outlet: all dryers have a 5 micron pre filter r at the inlet and a manually infinite adjustabledamper at the outlet.door : doors at provided at the front and or rear side of the dryer. Door lips are lined with silicon ruuber gasket to preventany leakages. Suitable locking is provided for the doors.air circulation : air circulation is done by specially designed recirculation blowers inside thedryer. The blower capacity , static & design depends on the size and model of dryer.

...more

Vacuum Filling Machine

vacuum filler is a rotary level filler which fills with vacuum principle and maintains same level while filling particular size adjustment. It is used for filling only non carbonated liquids. applications : to fill-liquor, pharma liquids, household liquids in glass rigid bottles and containers. salient features : machine is of simple design and with very less moving parts. Thus, easy to maintain. the bottle lifters are mechanical spring loaded. all change parts made out of uhmw. centralized lubrication. capable of handling bottles of any shape and size. speed variable with variable speed pulley. However, ac frequency drive can also be provided at an additional cost. inbuilt conveyor with overlapping at out feed end driven by imported speed variator. higher models fitted with automatic overflow system. safety hood aluminum s. S. Frame with toughened glass can also be provided at additional cost. easy change over from one size to another.

...more

Turbo Sifter

Turbo Sifter is used to sieve dry raw material in powder form before it is fed to Rapid mixer & wet granulator or High shear mixer.The Turbo Sifter is suitable for separation of foreign objects from dry powder before mixing, One can use mesh size from 4 to 25. this machine is used for mainly screening the formulations (in form of dry powder) before feeding it in to the high shear mixer or Fluid bed granulator.Turbo Sifter can also be mounted on castor wheel for mobility. Entire assembly and sieves can be removed for cleaning very easily.

Capacity : 400 kg / hour

...more

Tunnel Rinsing Machine

DESCRIPTION : High Speed Linear Bottle Washing Machine is most ideal for Round Bottles and finds wide application in PHARMA, FOOD & BEVERAGES INDUSTRIES. The automatic loading arrangement facilities loading of bottles on to SS wire mesh conveyor through feed conveyor or bottles are pushed manually from feed table. This saves manpower as bottles are feed into pockets automatically. The automatic unloading mechanism consists of unloading bottle continues on to turn table (Optional). OPERATION : Three-cycle rinsing allows flexibilities of various wash cycles such as fresh water, dematerialized water etc. as per the rinsing requirement of bottle. All the pumps are made of SS and all the water contact parts are made of SS 316 on a heavy base of SS structure. In tunnel design is such that separation is maintained between feeding zone and discharge zone of the cleaned containers. All the mechanical drives are separated and isolated from the washing zone. Approved materials only are used for construction, together with a careful choice of components, thereby taking in to consideration all aspects of sanitation and consequence complying with the pharmaceutical G.M.P. requirements. The quality of rinsing is ensured through 3 sets of inner and 2 sets of outer nozzles accurately placed to direct the jet at center of the bottle and the bottle comes out with water totally drained with minimum droplets of water. SALIENT FEATURES : High-pressure spray nozzles ensure perfect wash of Bottles. Interchangeable wash sequences. Totally fabricated from SS Materials, including the basic frame. No change parts required for washing of round bottle saving time of change over. (Change Parts require for Flat bottles & if change of neck size.) All parts coming in contact with washing zones / jet are made from SS 316 materials. The machine suitable for handling washes of round and flat glass bottle (With help of change parts). Water re-cycling arrangement is possible as per customer’s need. Machine is totally rigid and with stands continuous operation for long working. Hours without any trouble. Higher capacity centrifugal pump to wash bigger container. Third Tank & pump can be fitted (optional).

...more

Tube packing machine

At Shree Bhagwati Machtech (India) Pvt. Ltd, we manufacture high-performance tube filling machines for creams and ointments. Our complete stock of tube filling equipments include Automatic Tube Filling, Tube Filling Fully Automatic OintmentCream Manufacturing Plant, Toothpaste Manufacturing Plant, ointment manufacturing plant, and Contra Rotating Mixer. Our tube filling machines operate in an automatic process and are capable of filling tubes of diverse sizes. The ointment filling tools manufactured by us also offer superior performance while filling ointments and creams. Moreover, all the parts of our toothpaste filling devices are SS 316 complaint and adhere to the GMP quality standards. Execution of all the major transfers takes place with the help of vacuum, which prevents contamination.

...more

Tube Filling Machines

At Shree Bhagwati Machtech (India) Pvt. Ltd, we manufacture high-performance tube filling machines for creams and ointments. Our complete stock of tube filling equipments include Automatic Tube Filling, Tube Filling Fully Automatic OintmentCream Manufacturing Plant, Toothpaste Manufacturing Plant, ointment manufacturing plant, and Contra Rotating Mixer. Our tube filling machines operate in an automatic process and are capable of filling tubes of diverse sizes. The ointment filling tools manufactured by us also offer superior performance while filling ointments and creams. Moreover, all the parts of our toothpaste filling devices are SS 316 complaint and adhere to the GMP quality standards. Execution of all the major transfers takes place with the help of vacuum, which prevents contamination.

...more

tin packing machine

The Semi Automatic Flowmatic PLC Base Machine is compact and highly efficient machine with elegant look. This multifunction multi featured machine meets the custom requirements of Bulk filling 15Kg Tin with no restriction of liquid characteristics. The machine has its own pumping system to fill the programmed liquid in Jars. The flow of liquid is measured and converted in to electronic signals being controlled by the PLC base circuit. No mechanical adjustments are required to set different fill volumes with different sizes of containers. i.e. No change part is required.

...more

Tablet Punching Machine

Many model our manufacturing range Compression Machine For Tablets , Tablet Manufacturing machine, Pill Pressing Machine ,Bilayer Tablet Compression Machine, Automatic Tablet Press Machine, Single Sided Rotary Tablet Press , Tablet Punching Machine , Tablet Press Machines such as Single Rotary Tablet Press Machine, Next Gen-1 Heavy Duty Tablet Machine and Rotary Tablet Press Machine, High Speed Double Sided Rotary Tablet Press such as Double Sided Rotary Tablet Press, Rotary Tablet Press Machine, Tablet Press Model Tablet press machine Mega Press and Tablet press machine Press IV, Double Sided Rotary Tableting Machine such as Tablet Press Machine, Salt Tablet Press Machine, Double Rotary Tableting Machine and Tablet Press Model .

Type : No. of Stations

...more

tablet punches and dies

The team of Bhagwati has implemented its endless efforts for the improvement of press tool for tabletting machines. There is a vast development in the design and technique of making punches and dies. These punches and dies are made of hard core alloys ensuring their best suitability for pharmaceutical and chemical industrial conditions. They have the ability to improve the quality of tablets with respect to their external form.At present most of the pharmaceutical and chemical industries are not having a specialized undertaking that would ensure their requirement of standard punches and dies. We studied the requirements of both domestic and foreign industries and succeeded in providing ideal pressing tool machinery accordingly.Our Tableting Toolings Punch Die Sets for Tablet Press are made from high nickel, high chrome shock steel. Among the many factors that go into steel selection for us to manufacture Tableting Toolings Punch Die Sets for Tablet Press are tonnage required for the tableting, chemical atmosphere, abrasive nature of the product, turret speed, cup depth, location of embossing, bisect land and physical condition of the press. We also offer custom punch die sets on demand.

...more

Tablet Filling Machines

The Bhagwati Rotary Bottle washing Machine is compact and highly efficient machine with elegant look. This multi functional multi featured machine meets the GMP requirements of washing for glass and plastic bottles. The machine operates on the Rotary principle with “GENEVA” mechanism and requires manual loading and unloading of bottles.‘Bhagwati Linear Bottle Washing Machine is used for washing of Bottles and finds wide application in Pharmaceuticals Industries. The automatic loading arrangement facilities loading of Bottles on to SS wire mesh conveyor through feed conveyor or Bottles are pushed manually from feed table. This saves manpower as Bottles are feed into pockets automatically. The automatic unloading mechanism consists of unloading Bottle continues on to turn table (Optional)

...more

tablet dies

The team of Bhagwati has implemented its endless efforts for the improvement of press tool for tabletting machines. There is a vast development in the design and technique of making punches and dies. These punches and dies are made of hard core alloys ensuring their best suitability for pharmaceutical and chemical industrial conditions. They have the ability to improve the quality of tablets with respect to their external form.At present most of the pharmaceutical and chemical industries are not having a specialized undertaking that would ensure their requirement of standard punches and dies. We studied the requirements of both domestic and foreign industries and succeeded in providing ideal pressing tool machinery accordingly.

...more

Tablet Counting Machine

Bhagwati tablet counting and filling machine adopts advanced vibration and multi-channel feeder, computer control, dynamic scan counting, transfer the bottle automatically, system test automatically. The machine With Stop automatically function and other advanced technology. This machine designed with GMP standard. Compose the light, electric machinery to one set, which is suitable for tablet or capsule counting and filling in pharmaceutical or food business.

...more

Tablet Coating Machine

As one of the pioneering manufacturers of the Tablet Coating Machine, we, at Shree Bhagwati Machtech (India) Pvt. Ltd follow the top quality standards for designing our machines. The tablet coating machines manufactured by us have SS 304-complinat screen and parts. Moreover, the coating pan is highly durable and resistant to heat.Tablet Coating Pan is especially designed for film coating of oral solid dosage forms at controlled atmosphere in pharmaceutical industries ensuring user friendly operation. Benefits of our tablet coating equipment include effective mixing of final product bed, lowering emission of organic solvents, long term performance, automatic emptying and many more.

...more

Syrup Filling Machine

The Bhagwati Rotary Bottle washing Machine is compact and highly efficient machine with elegant look. This multi functional multi featured machine meets the GMP requirements of washing for glass and plastic bottles. The machine operates on the Rotary principle with �GENEVA� mechanism and requires manual loading and unloading of bottles.�Bhagwati Linear Bottle Washing Machine is used for washing of Bottles and finds wide application in Pharmaceuticals Industries. The automatic loading arrangement facilities loading of Bottles on to SS wire mesh conveyor through feed conveyor or Bottles are pushed manually from feed table. This saves manpower as Bottles are feed into pockets automatically. The automatic unloading mechanism consists of unloading Bottle continues on to turn table (Optional).

Model No : SBLBW-100

...more

syringe machine

Pre Filled Syringe Filling & Stoppering Machine Model PFS-SA-10 is very compact and elegant PLC. Based cGMP model for automatic filling and Stoppering operation of pre filled syringe. Operator has to keep a nest (tray) of 100 pre filled syringes over the SS jig. Then he has to put a jig to filling magazine and start the machine to filled syringes.Automatic filling cycle start in 10 steps with at a time 10 syringe will fill with help of perisatalistic pump or â valve lees syringe .

...more

sugar coating machine

Automated process.Conforms to cGMP.Flexible batch operations.Product protective handling to prevent chipping of tablets.Complete separation of production and technical area.Extremely user friendly software and operation through PLC.Excellent mixing and tumbling by special design of baffles.Made up of entirely of S.S.316.Advanced CIP system.Treatment of exhaust air for pollution free operation.

...moreBe first to Rate

Rate ThisOpening Hours