self cleaning online screen changer

Screen Changer In Operation Both screen in operation with all valves open. Close Valve No. 1 and open Valve ‘S’ for self cleaning for perfect cleaning the mesh. Close Valve No. 1 & Valve No. 2 i.e. on and change the mesh as required. Open Valve No. 2 slowly and completely. Again both lines are in operation. Accessories Special adaptors for die and barrel side as per your plant. Spare screen packs and heaters. Application & Usage It is absolutely necessary to filter plastic material by way of Screen hanger. Impurities will prevent the damage of the die & Bbarrel and increase the life. The final product will be consistently good. Filter mesh can be changed without stopping the extruder line. Without stopping the production of the line i.e. increase the production. Advantages Max. exploration of line due to without stop the plant. Elimination of scrap. Very easy operation. No wastage of material.

...more

Screen Changer

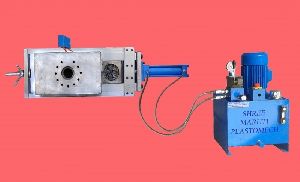

Platen type screen changer

Application : Screen changer suitable to all process & master batch plants. Filter mesh change easily just changing station. Station change 3 to 5 seconds with hydraulic power pack. Consistancy in quality to final product. Advantages : Increase production with quality. Leak proof. Down time decrease. Operation : Stop the machine Start the production change the idle station. Change station. Keep ready.

...more

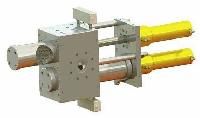

Platen Accumulator Screenchanger

Application : Suitable to all process & master batch plants. Filter mesh change easily just changing station. Station change 3 to 5 seconds with hydraulic power pack. Consistancy in quality to final product. Advantages : Increase production with quality. Leak proof. Down time decrease. Operation : Stop the machine Start the production change the idle station. Change station. Keep ready.

...more

manual plunger screen changer

General Features Operational : Six models are available. Filter mesh station will be change manually / hydraulically. Very easy to operate. Adaptor for mounting screen change as per your requirement. Consistency in quality of final product.

...more

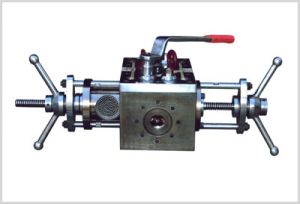

Lever type screen changer

General Features Operational : The screen (mesh) to be changed manually, when the other screen is under running. Die side and barrel side fitment will be done with your specification on extra / actual cost basis. Ceramic heaters are provided for better heating function. You can change the filter station without loosening the adapter bolts. Very easy to operate and leakage free Screen Changer. Easy to install and compact design.

...more

Continous Screen Changer

Screen Changer in Operation : All Valve are opened with both lines on running position. Close Valve 1 & 2 slowly and remove the plunger by puller and replace the mesh. The plunger placed in body by puller and tightened both of the plunger than open Valve no. 1 as marked so empty chamber of plunger will fill up the material without disturbing the flow. Then open Valve C for removing inside air and clean the material should come out from this Valve and open Valve No. 1 fully. And open Valve No.2 for output than close Valve C. This is again same 2 line working condition. Accessories : Adaptors for mounting the screen changer i.e. die & barrel side. Spares – Heaters, Screen packs. Application & Usage : Necessary to use screen changer for filtering the plastic material. Leak free design. Filter mesh change without stopping the extruder machine. Final product will be consistently good. 100% production without stopping plant. Advantages : Max. exploration of line due to without stop the plant. Elimination of scrap. Very easy operation. No. wastage of material.

...more

Cassate Screen Changer

Application : Screen changer suitable to all process & master batch plants. Filter mesh change easily just changing station. Station change 3 to 5 seconds with hydraulic power pack. Consistancy in quality to final product. Advantages : Increase production with quality. Leak proof. Down time decrease. Operation : Stop the machine. Start the production change the idle station. Change station. Keep ready.

...more

plastic processing machine

plastic processing plant

Be first to Rate

Rate ThisOpening Hours