wet drum permanent magnetic separator

How it worksThe liquid flows through a semicircular separating chamber beneath a stainless steel drum gather is a semicircular separating chamber through which the liquid flows. The cylinder consisting of permanent magnetic discs are positioned within the drum to which the magnetizable particles are attracted. By rotating the drum, the filter cake is lifted out of the slurry and the magnetic field.Salient Features Wet drum magnets have high magnetic recovery and discharge. The feed slurry recovers the magnetic. Available in single or multi-drum applications. Permanent magnet assembly eliminates coil burn-outs. The magnet / pole elements are bolted to a mild steel shaft. The drum is made from thick stainless steel for long life. Wet drum separators are available in a different configuration like a single drum, double drum, and multiple drums. In double drum, two separators are arranged back to back with a common feed back. Applications Glass Industry Chemical Industry Plastic Industry Mining Industry Food Industry Pharmaceuticals industry Foundry Industry

Application : Separating Iron, Chemicals, Food, Flour Particles

Weight : 100-200kg, 200-300kg, 300-400kg, 400-500kg, 500-600kg, 600-700kg, 700-800kg, 800-900kg

Color : Black, Blue, Brown, Grey, Light Green, Light White

Voltage : 110V, 220V, 380V, 440V

Automatic Grade : Automatic, Fully Automatic, Manual, Semi Automatic

Driven Type : Electric, Hydraulic, Mechanical, Pneumatic

Warranty : 1year

...more

Vibro Separator

Salient Features Flour and semolina mills Feed mills Seed cleaning plants Works on cereals cleaning and calibration centers. Aluminum Industries Sand Material

Voltage : 415

Condition : New

Warranty : 1 YEAR

After-Sales Service Provided : Yes

Feature : Flour and semolina mills.

Production Capacity : 30L to 3000L

...more

Vibratory Motor

Operating PrincipleUnbalance motors are asynchronous AC Motors with pairs of centrifugal weights fitted to the ends of the motor shafts. The size of the unbalance and with it the amplitude of the oscillation by the working unit can be adjusted by shifting the centrifugal weights when the motor is at a standstill.A stable, rigid motor shaft and roller bearings with a long service life allow the unbalance motors to be operated continuously even under difficult operating conditions. The unbalance motors are supplied in 2,4,6 and 8 Pole versions. This means the motor speed and therefore the oscillation frequency can be ideally selected to suit each particular application. The unbalance motors are also available in a special version for mains voltages up to 690V and for a mains frequency ranging from 50 Hz to 60 Hz.We Manufacture Following Types of Vibratory MotorsUnbalance Vibratory MotorCenter Flange Vibratory MotorDouble Flange Vibratory MotorFoot Mounted Vibratory MotorIndustrial Vibrator MotorTop Flange Vibratory Motor

...more

Vibratory Feeder

Details We Manufacture Following Types of Vibratory Feeder: Motorized Vibratory Feeder Electromagnetic Vibratory Feeder Technical Specifications The Mechanical Vibratory Feeder consists of a tray made out of Mild Steel. The body housing of the Vibrator is made from Heavy duty M.S.Plates. As the Motor get energized the Vibration sets the material in motion. The Vibration of the feeder will be controlled with the help of adjusting loads of the motor. The Feeder will be mounted on Heavy Duty Spring Bar/Brackets or Base Mounting. Application Linens can be provided for special applications e.g. Feeding of ORE and pellets in the blast furnace. Enclosed body for feeder can be a manufacturer for extracting minerals for storage bins and convey to kilns.

Certification : Iso

Application : Feeding, conveying and weighing

Condition : New

Warranty : 1 Year

Capacity(t/h) : 100 kg per/hr to 6000 kg/hr

...more

Vibrating table

Compaction Table: Heavy duty for maximum loads. –Standard or custom made to specification. Speed and impact adjustable Electro Magnetic Industries” compaction tables can be supplied with Pneumatic or Electric Vibrators. Most are both speed and force adjustable and Heavy-duty construction. “Built in” versatility means these tables can be used for packing, setting, casting concrete as well as fatigue testing. Vibration is isolated from the frame with inflatable air mounts, rubber mounts or springs. The motorized electromechanical vibrating table consists of a solid base plate and a vibrating top. The top platform vibrates at 1500/3000 vibrations per minute through two/one unbalanced vibration motor housed inside. The motors with the unbalanced load will generate the amplitude of 1.5 mm to 3 mm and that will shake the material and compact the material.

max weight : 600kg

Voltage : 380V

Material : Metal

Condition : New

Warranty : 1 year

Usage/Application : Industrial

...more

Vibrating Screening Machine

Vibrating Screen Machine is used for Vibrating Screen Machine For Chemicals Vibrating Screen Machine For Pharmaceuticals Vibrating Screen Machine For Aluminium Fluoride Vibrating Screen Machine For Spices Vibrating Screen Machine For Atta Vibrating Screen Machine For Suji Vibrating Screen Machine For Haldi powder Vibrating Screen Machine For Mirch Powder Vibrating Screen Machine For Mineral Garnet Vibrating Screen Machine For Zircon Vibrating Screen Machine For Medicines Vibrating Screen Machine For Bulk Drug Vibrating Screen Machine For Plastic Vibrating Screen Machine For Rotomoulding Machine Vibrating Screen Machine For Refractories Vibrating Screen Machine For Wood Chips Vibrating Screen Machine For Ceramic Pulp Vibrating Screen Machine For Paper Mill Vibrating Screen MachineFor Packaging Line

Certification : CE Certified, ISO 9001:2008

Weight : 100-200kg, 200-300kg, 300-400kg, 400-500kg

Color : Blue, Red, Green, Silver, Sky Blue, Black

Voltage : 110V, 220V, 380V, 440V

Condition : New

Automatic Grade : Automatic, Fully Automatic, Manual, Semi Automatic

Power : 1-3kw, 3-6kw, 6-9kw, 9-12kw

...more

Tunnel Type Demagnetizer

Features Used for removing surface residual magnetism of round & square jobs Operate on 415 volt 2 phase A/c Supply Suitable for continuous duty cycle Current 10 amps Fiber body is used for scratch free demagnetizing MCB is provided for safety Special sizes are manufactured as per requirement

Condition : New

Warranty : 1 Year

After-Sales Service Provided : Any where off sight

...more

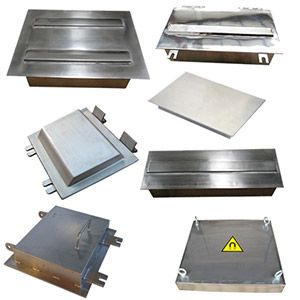

Trap Magnet

Application : Industrial

Thickness : 2-5 mm

Certification : CE Certified

...more

Suspension Magnet

Suspension magnet are used in the bulk production of Cutlets Glass Coffee Cereals Minerals Coal Sugar

Condition : New

Warranty : 1 Year

After-Sales Service Provided : YES

Size : 145mm

Application : Automobile industries

...more

Spout Magnet

Features Easily installed Highly effective and consistent performance Flanges or connections made to your requirements Easily cleaned Ideal for free flowing powders and granules: plastics, food ingredients Hygienic sealed quick release door Specification Available with either ceramic or powerful rare earth magnets Manufactured to fit various pipelines ranging from 50mm - 350mm diameter Round door - suitable for pressure up to 0.5 bar Flat door - Suitable for pressure up to 2 bar Specials available including full stainless steel manufacture and higher pressure resistant units Magnet strength up to 10,000 gauss

Thickness : 2-5 mm

Certification : CE Certified

Application : Industrial

...more

Chuck Series Svm- 710 Round Magnet

Holding device for Rotary surface grinding and also for Lathe & cylindrical grinding machines. Accuracy as per IS : 4816- 1987 Magnetic pullis 20-40% more than IS specification. Assembled with Powerful Magnets. On-Off by key

...more

Round Magnetic Chuck

Holding device for Rotary surface grinding and also for Lathe & cylindrical grinding machines. Accuracy as per IS : 4816- 1987 Magnetic pullis 20-40% more than IS specification. Assembled with Powerful Magnets. On-Off by key

...more

Rotary Magnet

Salient Features Dust-tight, sanitary construction. Custom designed housings. Easy Cleaning. Low Maintenance. High strength rare earth magnets. Applications For chemicals and Pharmaceutical Industries. Flour milling industries. Mineral processing industries. Born milling industries. Features and Options of Demountable Grate Rotary Magnet / Magnetic Separator Rotary valve body option Rotor support Magnetic protection without restricting product flow Rare Earth magnets encased in stainless steel tube provide maximum cleaning efficiency Designed to remove ferrous particles from the product Air purged shaft seals Air service unit Direct drive Hand demountable easy clean design

Material : Metal

Condition : New

Thickness : 2-5 mm

Shape : Rectangle

...more

Roller Type Magnetic Separator

Shree Vishwakarma Magnets is a leading manufacturer of High Intensity Roller Type Magnetic Separator with 15 years of experience. We are developed cost-effective, high-intensity, high-gradient, permanent magnetic roller separators with the indigenous technology which has been used successfully in industrial minerals applications. High-intensity roller type magnetic separator incorporates high energy rare earth neodymium Permanent Magnetic Roller assembly, which is manufactured and assembled under strict quality control and specification to generate unsurpassed magnetic field gradients. Under this high-intensity magnetic field, weakly magnetic contamination can be easily removed easily and efficiently. Working Principle: In High Intensity Roller Magnetic Separator, a short conveyor belt envelopes the magnetic roll and a tensioning ideal roll. A suitable feeder discharges materials on the belt. The ferromagnetic and paramagnetic particles adhere to the belt while the nonmagnetic particles flow freely off at the end of the conveyor. Features: Magnetic Rollers is available in 75(3 inches) & 100mm(4 inches), 150mm(6 inches) , 200mm (8 inches). More Size as Per Client Required. We Are Using a Motor 0.5 HP to 2 HP as per Machine dimension and Also We are using Standard Company Gearbox with Variant ratio as per material flowrate. Vibratory feeder provided with high quality unbalanced vibratory motors. Abrasion resistant endless conveyor Belts with a thickness of 0.35mm to 5 mm is provided for the Machine. Salient Features: Vibratory Feeder with controls provided for Feeding. The high efficiency of the iron separation system. Abrasion resistant endless conveyor belt with a thickness of 0.35mm to 5 mm is provided for the Machine. Multi-stage system up to 6 stages is available. Different Magnetic Strengths are available: 8,000 Gauss 10,000 to 12,000 Gauss High Intensity Roller Type Magnetic Separator is used for Cleaning and Processing for various types of Grains: Rice Cleaning Garnet Sand Silica Sand Mineral Product Wheat Cleaning Corn Cleaning Pulses Cleaning Spices Cleaning Seed Cleaning Semolina Cleaning Chili Flakes Sesame Cleaning Cumin Cleaning Fennel Seed Cleaning Applications: Shree Vishwakarma Magnets machines are mostly used in various industries like minerals applications such as abrasive, refractory and ceramic raw material beneficiation, alumina, silica, carbide, magnetite, quartzite, etc. Glass raw materials cleaning silica and quartz, feldspar, dolomite, etc. Ultra high purity quartz cleaning, graphite upgrading, manganese ore beneficiation, bauxite upgrading, diamond ore beneficiation, selective separation of garnet/limonite/rutile, zircon, beneficiation of iron ore, recovery of metals from slag, removal of ferrous silicates from limestone, magnesite etc. Also, our magnetic separators are used as magnetic destoner for food processing industries which can remove mud balls from wheat, rice, sesame, semolina, cumin, Fennel, chili flakes and many other food products. Testing Facilities: Live working of a machine will be demonstrated at our workplace. A small sample of around 5-10 Kgs. of material can be tested free of cost and performance of our machine can be demonstrate.

...more

rare earth magnetic equipments

The Sintered NDFeB Magnet manufactured by us is a high quality and high performance magnet from the rare earth class of magnets. This magnet manufactured by using many ingredients, out of which the primary ingredients are neodymium (Nd), iron (Fe), and boron (B). This magnet is not suitable for high temperature applications. The magnetic properties of this magnet are very high in comparison to its price. These magnets are generally manufactured by us in large block shapes as well as according to customized needs. The coating is applied over the magnet only after taking into consideration the environment in which it is to be used.

...more

Pneumatically Operated Hump Magnet

Salient Features Remove ferrous contaminant Robust design Provide self-cleaning solution Low maintenance

Type : Magnetic

Thickness : 2-5 mm

Certification : CE Certified

Shape : Rectangle

Application : Industrial

...more

Plate Magnet

Salient Features Magnetic Plate consists of high coercivity modern anisotropic. Magnetic separators capture maximum common ferrous debris. Permanent magnet like ferrite/rare earth magnet. Durable stainless steel construction. The plate magnets can be cleaned manually also. Simple to install and no maintenance. Strong & rugged construction with M.S or S.S 304/316 construction.

Type : Magnetic

Shape : Rectangle

Thickness : 2-5 mm

Certification : CE Certified

Application : Industrial

...more

Permanent Magnetic Lifter

Features Zero electricity required Forged hook for high mechanical strength and durability Precision machined assembly block in single piece to enhance efficiency Designed for safety and light weight Fool proof locking system with an easy to use "on" and "off" lever 3 times rated capacity factor of safety to meet the safety standards as per international standards for under the hook devices Test certificate for safety factor from government approved third party No Maintenance and Operating cost No damage to the work piece being lifted Very Compact Benefits Lifting Magnets use space more effectively. Eliminates the need to gauge and increase stacking height As less as one operator can move large and heavy work piece safely and easily using Magnetic Lifters Lifting Magnets save labour and time - improves productivity Construction: Permanent Magnet Lifters have strong magnetic field path produced by NdFeB Magnetic materials. "On" and "Off" of the magnetic path is controlled by turning the lever manually. There are shackles on the top of Magnetic Lifter for lifting. Operating Instructions The work piece surface (magnetic ferrous surface) and magnet pole surface must be clean and smooth to achieve maximum efficiency. Ground and machined surface are ideal but a good clean surface on a ferrous or casting is acceptable provided a sufficiently flat area available for good magnetic contract with the work piece There should be no air gap / inclusions between the magnet pole and the job surface Place the magnet on the ferrous surface. Unlock the lever by pulling it out and then turn it to the “ON“ position. Once it is made “ON”, lock it by releasing it. For making it “OFF”, please follow the similar procedure. (Do not place on wooden surface OR non-magnetic surface - it will not be possible to operate Lever to “ON” position) Move the load smoothly, avoid shocks and collisions To place / drop the lifted material, operate the lever to the “OFF” position When not in use Apply Grease / Oil on Magnetic Poles surface to prevent it from rusting and Place it on thick wooden plank to safeguard its Magnetic poles from any damages, scratches etc. Safety Instructions Place the magnet on the Ferrous Surface in “OFF” position and then make it “ON”. Do not make it ON without keeping it on ferrous surface The magnet is to be placed on the center, i.e. centering to the center of gravity of the load and then lift While handling the load, no person should be allowed in the immediate danger zone Ensure that the lever is made “OFF” after resting the load at desired place in balance position Important Factors for the Safe Operation of Lifting Devices Load characteristics other than just weight must be considered in order to determine the weight that any magnetic lifter can lift. This statement is true for any lifting magnets because they all operate on the same fundamental laws of Physics. Magnetic power is pictured as lines of force flowing from North to South Pole. Anything that limits the flow of these magnetic lines of force obviously reduces the magnet’s lifting ability. There are four important factors which limit the flow of these lines of force. Load Surface Conditions Magnetic lines of force do not flow easily through air, they need iron in order to flow freely. Therefore, anything that creates an air gap between a magnet and the load, limits the flow of magnetic force and thus reduces the lifting capacity of a magnet. Paper, dirt, rust, paint and scale act in the same way as air, so also a rough surface finish between the magnet and the load. Load Length and Width When the length or width of a load increases, it ceases to lie flat and the load begins to drop at the edges. The drooping/sagging of the load can create an air gap between the load and the magnet. If this occurs then the lifting capacity of the magnet is reduced. Load Thickness Magnetic lines of force are more effective when they flow through iron instead of air. The thicker the load, the more the lines of magnetic force. After a certain thickness of load, no more lines of force will flow because the magnet has reached its full capacity. Thin material (load) means less iron available and thus fewer lines of magnetic force flow from the magnet into the load. Therefore, the lifting ability of the magnet is reduced. Every magnet is rated for minimum thickness of load to reach full lifting capacity. Below such thickness of load will be rate the lifting capacity of the magnet. In general, it can be said the load must be thicker than the width of one of the magnet poles. Load Alloy Low carbon steels, such as soft Iron or Mild Steel are nearly as good conductors of magnetic lines of force as pure iron. However, if the alloys contain nonmagnetic materials, they decrease the ability of magnetic lines of force to flow into the load. An alloy such as ANSI304 of Stainless steel is almost as poor conductor of magnetic force as air. Why Permanent Magnetic Lifters? These magnetic Lifters are ruggedly built High Lifting Capacity with respect to size & weight Works without Electrical Power No maintenance and operational costs Very easy to use - Save time & energy Made with high energy rare earth magnets (NdFeB) Mechanical Switching by turning a lever with a lock System against switching off accidentally No damage to the work piece being lifted Easily transportable Reliable

Application : Material Handeling

Condition : Good

Warranty : 1year

...more

permanent magnetic drum pulley

Features The magnetic pulleys can be installed easily at conveyor discharge They give complete magnetic protection over the entire face of the pulley for removing ferrous contaminants For different conveyors the magnetic pulleys of different sizes are available The pulleys either use ceramic magnets or powerful rare earth magnets General Specification Flux density: 8500 ± 200 gauss Maximum operating temperature 450?C In all pulleys, best grade St. Ferrite/Rear Earth magnets are used for construction. The outer face and the end plates of the magnetic pulley are made out of stainless steel The magnetic pulley removes contaminants like nuts, bolts, wire, tools etc. It protects equipment, and product from the hazards of tramp iron Types High Intensity – (NdFeb Magnet – 8500 Gauss) Low Intensity - ( Ferrite Magnet - 3500 Gauss) Customized Pulley DesignsShree Vishwakarma Magnets also makes custom designed Magnetic Pulleys to precisely fit customer’s application. Following information is required: Type of material Conveyor belt width Belt Speed Size and concentration of the contamination Burden depth InstallationInstallation is often very simple. Four bolts on a set of pillow block bearings normally hold the pulley in place. Loosen the conveyor belt, remove the old pulley and install the magnetized pulley. This type of installation does not require electricity.

Material : MS, Stainless Steel

Usage : Industrial

...more

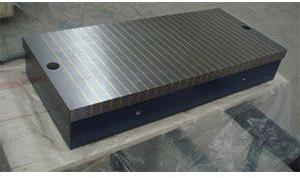

Chuck Series Svm- 837 Permanent Magnet

Details Holding device for surface grinding machine, Tool & cutter grinder, Spark erosion machines & also for light milling. The working face & bottom face are perfectly parallel. Assembled with Powerful Magnets. Poles individually magnetized for Full loading power. Magnetic pull 40-50% more than IS specification. Better magnetic grip due to close poles. Suitable to hold thin & small jobs. Easy operated ON-OFF lever.

Size : Customized

Coating : Zn/Ni/Epoxy

...more

Heavy Duty Permanent Magnetic Chuck

Holding device for surface grinding machine, Tool & cutter grinder, Spark erosion machines Accuracy as per ISa : 4816 - 1987 Assembled with powerful Magnets Poles individually magnetized for full loading power Magnetic Pull is 40-70% more than IS specification Bottom plate has suitable extension to clamp on table Easy operated ON-OFF lever.

Application : Suitable to hold thin & small jobs.

...more

Overband Magnetic Separator

Salient Features Used in either ceramic or powerful rare earth magnet. Separator body covering. Low maintenance Roughest construction High efficiency of separation Long belt life How Does it Work?Magnetic Separation Process: The Suspended Permanent Magnet is placed over the conveying belts carrying the material. This Suspended Magnet system arrests Ferromagnetic materials from distance of 300mm/12 inches from feed material which is transported through the production process.NOTE The attraction distance trial is taken at a point below the geometrical center point of the suspended magnet assembly. The above results are obtained when free path is available for tramp iron particle. The above chart is given for the reference. One may get a deviation of 1 to 2 inches in attraction distance depending on actual conditions. Construction Two U-section pieces are fixed on the Magnet by fastening ears and are supporting bearings of Drums. Drums are equipped with shafts mounted on removable hubs. All bearings equipped with stakes for tightening the belt. The belt is driven by a Reduction Gear Coupled to Electric Motor / Geared Motor by V-belts. Magnet UnitThe Magnet is made of High-Intensity Strontium Ferrite / Rare Earth Magnets and is guaranteed for the Magnetic Power throughout the life of the installation. A Non – Magnetic Stainless steel Plate is provided to cover the poles of Magnet. There is no need for any electrical supply or maintenance.

Voltage : 110V, 220V, 380V, 440V

Automatic Grade : Automatic, Fully Automatic, Semi Automatic

Power : 1-3kw, 3-6kw

Driven Type : Electric, Hydraulic, Pneumatic

...more

Overband Cross Belt Magnetic Separator

Salient Features Used in either ceramic or powerful rare earth magnet. Separator body covering. Low maintenance Roughest construction High efficiency of separation Long belt life Applications There are total five types of separators RE designed to operate at a predetermined working gap over the conveyor: The speed of the belt , the nature of the product, its density, its granulometry and the size of the pieces which have to be extracted are on of the parameters to be taken into consideration when choosing the type of Overband. Five type of Separators Redesigned to operate at a predetermined working gap over the conveyor : 100, 150, 200, 250 and 300mm. 100mm 150mm 200mm 250mm 300mm ConstructionTwo U-section pieces are fixed on the Magnet by Fastening ears and are supporting bearings of Drums. Drums are equipped with shafts mounted on removable hubs. All bearings equipped with stakes for tightening the belt.The belt is driven by a Reduction Gear Coupled to Electric Motor / Geared Motor by Vee- belts.Magnet Unit The Magnet is made of High-Intensity Strontium Ferrite / Rare Earth Magnets and is guaranteed for the Magnetic Power throughout the life of the installation. A Non – Magnetic Stainless steel Plate is provided to cover the poles of Magnet. There is no need for any electrical supply or maintenance.InstallationThese units can be installed either in-line over the terminal head pulley (Fig – 1. ), or transversal to the conveyor (Fig – 2). In both cases, it is necessary to foresee Non- Magnetic products under the Magnetic Field.The most effective position is inline (Fig – 1) over the head pulley. The material being conveyed is in virtual Suspension and Tramp Iron is, therefore, more readily extracted. Very good results are obtained by combining a Permanent Magnetic Overband with Permanent Magnetic Pulley at the discharge end.

Weight : 100-1000kg, 1000-2000kg, 2000-3000kg, 3000-4000kg

Color : Black, Blue, Brown, Grey, Light Green, Light White

Automatic Grade : Automatic, Fully Automatic

Driven Type : Electric, Hydraulic, Pneumatic

Warranty : 1year

Usage : Removing Liquid Magnetic Components

...more

Neodymium Magnet

Size : 10mm X 2mm, 4mm X 1mm, 4mm X 2mm, 5mm X 2mm, 6mm X 3mm

Shape : Blocks, Rings, Rod, Sheet, Trapezoid

Certification : Iso Certified

Application : Generators, Industrial Magnet, Motors, Printing, Speakers

Grade : N35, N38, N40, N42, N52

Coating : Epoxy, Ni, Zn

Certification : Iso Certified

Composite : NdFeB Magnet

...moreBe first to Rate

Rate ThisOpening Hours