water mixers

Clients can avail from us Water Mixers, also known as Flash Mixers that are made to handle both clear water and waste water mixing after addition of coagulants for efficient formation of flocs thus increasing the settling efficiency of the water to be treated. The agitators with shafts in Water Mixer are made of stainless steel resulting in long functional life of the equipment. The Water Mixers can be availed in different sizes from us. We are a prominent Water Mixer Manufacturer, Supplier and Exporter in Karnataka, India.

...more

Waste water Clarifiers

Clients can avail from us different models of Waste Water Clarifiers that are designed to handle waste water of all types. Waste Water Clarifiers are especially designed to remove the sludge settled at the bottom of the tank so that the clear water overflows from the top into the over flow launder. The Waste Water Clarifiers are manufactured in both models such as central driven and peripheral driven depending on the size of the tanks. The Waste Water Clarifiers can be availed at affordable prices from us. We are a well-known Waste Water Clarifier Manufacturer, Supplier and Exporter in Karnataka, India.

...more

Vibrating Screens

surface aerator

We are one of the extensively sought-after Surface Aerator Manufacturers, Suppliers and Exporters in Karnataka, India. We make fixed slow speed Surface Aerators that are designed to work under worst conditions without any problem. Made using advanced production techniques, the Surface Aerator ensures high oxygen transfer capacity. The Aerators impellers are manufactured with a conical surface to ensure maximum flashing of water so that there is maximum oxygen absorption in the waste water and minimum energy consumption. The Surface Aerators can be manufactured both in Mild Steel and Stainless Steel depending on the clients' requirement.Attributes Of Surface Aerator. Robustr. Very efficient. Low initial cost. Low maintenance. Easy to run and maintain

...more

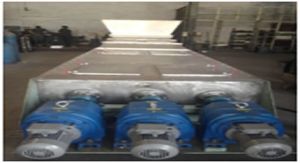

Screw Conveyor

rotary drum screens

Is the most advanced fine rotary drum screen now available in India. Screens are highly recommended as primary screening equipment in municipal sewage treatment plant and effluent treatment plants of various industries like Food processing, Rayon and textiles, Paper and pulp, Pharmaceuticals, Tanneries, Slaughter houses and so on. Is installed at an inclination of 35° with the horizontal in to the channel of treatment plant. The wastewater flows in to the open end of the wedge wire drum. While the filtered wastewater comes out from the sides of the drum passing though the wedge wire, the solids of the size more than the bar spacing are retained on the surface of the drum itself.

...more

Rotary Drum Screen

An innovative, rotary drum type fine bar screen for sewage and effluent treatment plants.APPLICATIONIs the most advanced fine rotary drum screen now available in India. Screens are highly recommended as primary screening equipment in municipal sewage treatment plant and effluent treatment plants of various industries like Food processing, Rayon and textiles, Paper and pulp, Pharmaceuticals, Tanneries, Slaughter houses and so on. WORKING Is installed at an inclination of 35° with the horizontal in to the channel of treatment plant. The wastewater flows in to the open end of the wedge wire drum. While the filtered wastewater comes out from the sides of the drum passing though the wedge wire, the solids of the size more than the bar spacing are retained on the surface of the drum itself. Owing to the blockage by the retained solids, the water level increases on the upstream of the screen. When the water level reaches to the pre-determined level, by virtue of the signal transmitted to the drive, the raking arm mounted on the drive shaft starts rotating. The comb mounted on the raking arm sweeps the drum and deposits the solids on to the collection trough at the center of the drum. The high-pressure water jet assists the deposition. From the trough the solids are conveyed to the washing and compaction zone where high-pressure water jet washes the solids and removes the soluble component. The water used for washing containing soluble components is sent back to the wastewater stream though the pipe.The washed solids free of faces are dewatered by squeezing in the compaction zone before the solids are finally discharged in the container or on to the belt conveyor from the discharge point.SLOT WIDTH : Slot width range from 1 to 6 mm. MATERIAL OF CONSTRUCTION To prevent from corrosion and to provide longer life fine screens are completely made from stainless steel AISI 304 grade as standard. Other grades of stainless steels are available up on request. ADVANTAGES. Rugged mechanical construction - Very long life.. Compact design-Low space requirement. Inclined at 35 Deg- Increased operational efficiency.. Completely made of stainless steel- Very long life. Higher capture rate - Ability to handle diverse waste. Self cleaning- No entrapment of solids.. Minimum moving parts-Lower wear and tear, minimum maintenance, Long life. Simple installation and operation... Factory assembled and movement tested- Faster erection.. Usage of V- wedge wire- Efficient removal of waste, low head loss. In built washing and compaction-Very hygienic and reduced weight of waste

...more

Roller Screening Machine

Reactor Clarifier

we are designed and built to provide the most economical solution to precipitation and clarification requirements in industrial and minerals processes. The basic machine design provides for flash mix, coagulation, flocculation, solids recirculation, clarification, and positive sludge removal in a single basin - eliminating the need for multiple tanks and associated piping and pumping. All units are backed by over 50 years experience in engineering and manufacturing assuring the best fit to unique plant requirements. Reactor-ClarifierT units are used for softening, turbidity removal, and taste and odor removal applications.Our units combine a large diameter, slow speed concentric turbine generating high volume internal recirculation to promote mixing, flocculation and solids-contact. The recirculation system is designed to promote particle growth and improve the removal of suspended solids. Raw influent immediately contacts a large volume of dense floc from previously precipitated solids in the recirculation drum and is pumped upward by the turbine. Depending on the application, a volume of 8 to 20 times the maximum influent rate is recirculated by the turbine to mix with new incoming feed, while the final effluent passe

...more

Pressure Sand Filters

We provide Pressure Sand Filters that can be made both vertical and horizontal depending on the quantity of the water to be filtered. The Pressure Sand Filters are provided with a big manhole to provide access to the operators to go inside the filters for any maintenance work or inspection of the inside surfaces. Pressure Sand Filters as well as other Filters, manufactured by us, are efficient and have long life. We are a renowned Pressure Sand Filter Manufacturer, Supplier and Exporter in Karnataka, India.

...more

Clariflocculators

We offer clariflocculator centrally mechanism that is suitable in the RCC circular basins. For continuous flocculation and setting of solids, this mechanism is absolutely suitable. Later on the settled solid is removed from the center of the tanks. As per our design specifications, the recommendable slope ration at the bottom of the clariflocculator tank is 1:12 and thus the sludge can be efficiently removed out. The centrally clariflocculators consist of the following types of components.

...more

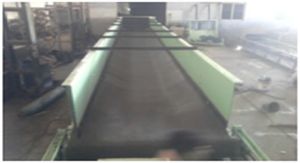

Belt Conveyor

Centrally Driven Clarifier

We offer clariflocculator centrally mechanism that is suitable in the RCC circular basins. For continuous flocculation and setting of solids, this mechanism is absolutely suitable. Later on the settled solid is removed from the center of the tanks. As per our design specifications, the recommendable slope ration at the bottom of the clariflocculator tank is 1:12 and thus the sludge can be efficiently removed out. The centrally clariflocculators consist of the following types of components.

...more

Clariflocculator Peripherally

We offer a wide range of high efficient clariflocculator peripherally system that is extremely suitable for RCC circular basin. For continuous setting and flocculation of solids, these are extensively used. These can also remove the settle solids from the tank's centers

...moreBe first to Rate

Rate ThisOpening Hours