Industrial Masala Grinder

20,500 Per Piece

spice pulverizer machine

Get Price Quote

We make sure to design the best spice grinder that can be used to grind all kinds of spices, dead leaves, roots, etc. The composition of our masala grinder varies. Customers may ponder on acrylic, wood and metal. Our spice grinding machine is usually made of MS Body. This is supported by other materials. Known for its durability, our masala grinder machine can definitely stand the test of time. It may be utilized both for commercial or home use. This can be enjoyed without worrying on the masala grinding machine price. The same is also the case with our space grinding machine price. With this, we made sure to offer reliable products that are affordable enough for our customers to support.Our masala making machine is crafted by people who are trained to understand the mechanisms of chili grinding machine. We are one of the most dependable masala grinding machine manufacturers that people in need can depend on. With our spice pulverizer and masala pulverizer, grinding spices would not have to be a difficult endeavour to undertake. Choose among a myriad of grinder styles we offer. This spice grinder does not only look good, it also performs best. Check out our selections now!

Best Deals from Spice Processing Plant

Corn / Maize Starch Plant Machinery

Get Price Quote

1 Piece(s) (MOQ)

Driven by technical excellence, we are counted as the topmost manufacture, exporter and supplier of excellent quality range of CornMaize 1st & 2nd Stage Coarse Grinder (Wet Process) that is used for grinding Corn Maize and other grains with utmost uniformity. Proposed grinder is designed and manufactured in line with international standards using quality-approved basic materials and latest methodology. Further, the offered grinder is tested on defined quality parameters to ensure its optimum functionality. Clients can avail thisCornMaize 1st & 2nd Stage Coarse Grinder (Wet Process) in several sizes, designs and other specifications at industry leading price. Features: Capacity - Upto 300 TPD. Material used: Mild Steel or Stainless Steel.

kandap machine

Get Price Quote

1 Piece(s) (MOQ)

We are offering kandap machine.

starch plant

Get Price Quote

starch plant, dewatering screw press, Screw Press, Chemical Plant

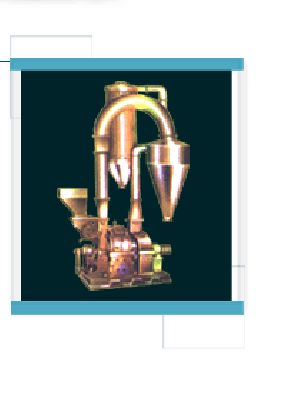

Impact Pulverizer

Get Price Quote

the perfect impact pulverizer meets most capacity requirements. It lend themselves to a wide degree of adjustment with finesse of the finished products ranging from about 60 mesh to bulk passing through 300 mesh depending to a considerable extent on the particular materials being handled. It combine grinding, classifying and conveying all in one single unit. it grinds with ease, economy and safety offering a wide range of particle sizing of any non-abrasive material, hard or soft from granular to finest dust up to 300 mesh. principles of impact pulverizer operation : the perfect impact pulverizer consists of and encased rotor carrying swing hammers, whizzer classifier for finess regulation and pressure gradient creator mounted on a solid shaft. Raw material from the feed hopper enters manually or automatically roll feeder and as the feeder and as the feeder pockets rotate spills into the grinding chamber. The impact to the hammers on the feed material against the liner plates reduces it into fine powder. The ground material is carried towards the wizzer classifier for clarification and the over sizw particles are rejected by the finess regulators (whizzer classifier) and returns to the grinding chamber for further grinding. Classified material is then conveyed into the cyclone for collection and bagging. A dust collector is provided in the system for ensuring dustless operation and no loss of ground powder.

Impact Pulveriser

Get Price Quote

The Techno Wings brand impact pulveriser meets most capacity requirements. It lend themselves to a wide degree of adjustment with finesse of the finished products ranging from about 60 mesh to bulk passing through 300 mesh depending to a considerable extent on the particular materials being handled. It combines grinding, classifying and conveying all in one single unit. It grinds with easy, economy and safety offering a wide range of particle sizing of any non-abrasive material, hard or soft from granular to finest dust up to 300 meshes. Operating principle of impact pulveriser The techno wings impact pulveriser consists of and encased rotor-carrying swing hammers, whizzed classifier for finesse regulation and blower fan mounted on a solid shaft. Raw material from the feed hopper enters manually or automatically roll feeder and as the feeder and as the feeder pockets rotate spills into the grinding chamber. The impact to the hammers on the feed material against the liner plates reduces it into fine powder. The ground material carried towards the whizzed classifier for clarification and the finesse regulators (whizzed classifier) and returns to the grinding chamber for further grinding reject the oversize particles. Classified material then conveyed into the cyclone for collection and bagging. A dust collector provided in the system for ensuring dustless operation and no loss of ground powder. Key features of impact pulveriser Unique and reliable design The impact series pulverisers are highly effective as well as nonstop continuous pulverizing process. Compact size. Dust free operation. Ideal for dry crushing. Increased production leading to faster return on the investments. Hardened &fully machined salving type beaters thus less wears &tears. All rotating parts are dynamically balanced for reducing friction losses and noise. Standard accessories of impact pulveriser Impact pulveriser's &motor pulley Suitable numbers of cotton balloons. Anti vibrating foundation stand with adjustable rail for motor Extra accessories of impact pulveriser Suitable totally enclosed fan cooled single or three phase sq. Cage motor as per is: 325{(special power can be accommodated): 110/220/380/415 volts, 50/60 Hz ,3 phase} Suitable starters, main switch, ampere meter, capacitor for three phase V belts Contacting parts stainless steel 304 / 316 can be accommodated. Application of impact pulveriser The techno wings impact pulveriser are used for a wide range of application e.g. Agricultural, chemicals, carbon &graphite, coal, coke, coconut shell &wood saw dust, clay, dye stuff &pigments, detergents, ferro alloys fertilizers, fillers, food products, herbs &spices, insecticides and pesticides, katha, marine feeds, minerals, plastics, pharmaceuticals, resins, wheat, turmeric, bangle grams, dehydrated Onion, Dehydrated Garlic, pulses, peas, sandalwood, Snuff, etc.

16 DTC Masala Mill

Get Price Quote

16 DTC Masala Mill, Table Top Domestic Flour Mill

Masala powder machine

Get Price Quote

Masala powder machine, FLOUR MILL, oil machine, Box Type Atta Chakki

kandap machine

Get Price Quote

kandap machine, d p pulveriser, tp motor, tp flanged motor

kandap machine

Get Price Quote

kandap machine, FLOUR MILL, mini pulverizer, Pulverizers, Sevai Machine

kandap machine

Get Price Quote

kandap machine, grain mill, Ghar Ghanti Flour Mill

Red Chilli Pounding Machine

Get Price Quote

Red Chilli Pounding Machine, Flour Mill Electric Motor, SS Body Flour Mill