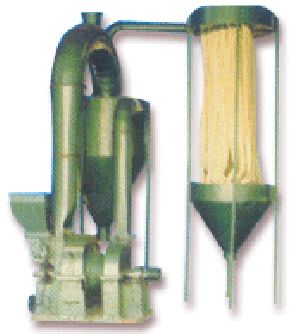

Impact Pulverizer

Get Price Quote

We are offering impact pulverizer the raw material to be pulverized enters into grinding chamber through the hopper and automatic rotary feeder. The impact of the hammer on the feed material against the liner plates reduces it into fine powder. The ground material is carried towards the whizzer classifier for classification and the over size particles are rejected by the classifier and returns to the crushing chamber for further grinding. The classified material is then conveyed into the cyclone for collection and bagging. A dust collector is provided in the system for ensuring dust free operation and no loss of ground powder advantage: impact pulverizers are most qualitative and lend themselves to a wide degree of adjustment with fineness of the finished products. In minerals and chemicals the fineness is possible from 60 to 300 meshes. Pulverisers are screen less so the possibility of chocking or jamming is ruled out. In built fan, cyclone and dust collector ensure dust free operation. Adjustable feed drive with the help of standard gear box. It has heavy duty base frame with all the ducts and pipes. application: for minerals, chemicals, china clay, dyes, pigments, saw dust, turmeric, besan, & etc.

PIN MILL / SUGAR PIN MILL / SUGAR MILL MACHINE

300,000 Per Set

1 Set(s) (MOQ)

Best Deals from Spice Processing Plant

Impact Pulverizer

Get Price Quote

An extra heavily constructed machine designed to pulverize even rocks and minerals of medium hardness. Fineness, ranging among 100 meshes to 300 meshes (150 to 50 microns) and in some cases even 500 meshes. Non concrete foundation - frame with AVM pads may be provided. The equipment is suitable for medium hard minerals, chemicals, bulk drugs, coal, paints, dyes and pigments, herbs, seed, etc.

Blended Spices Grinding Plant

Get Price Quote

Try our unbeaten range of Blended Spices Grinding Plants, if looking for the machines that grind products like coriander, chilies, and other blended spices in most decorous manner. Made by seasoned professionals, these Grinding Plants excel in terms of operational fluency, robustness and durability. Also, they require negligible upkeep. For convenient choices, we dole them out in tailored specifications at market-leading prices.

Impact Pulveriser

Get Price Quote

We are among the distinguished names in the industry for manufacturing and supplying Impact Pulveriser, which is used for the powdering of substances by means of continuous hammering in pharmaceutical, chemical, fertilizer and food processing industries. The offered pulverizer is exceptional in performance and is ideal for heavy duty. It is resistant to abrasions and is available in various specifications.

salt washery

Get Price Quote

1 Set(s) (MOQ)

kandap machine

Get Price Quote

1 Piece(s) (MOQ)

We are offering kandap machine.

Impact Pulverizer

Get Price Quote

An extra heavily constructed machine designed to pulverize even rocks and minerals of medium hardness. fineness, ranging among 100 mesh to 300 mesh (150 to 50 microns) and in some cases even 500 mesh. Non concrete foundation - frame with AVM pads may be provided. The equipment is suitable for medium hard minerals, chemicals, bulk drugs, coal, paints, dyes and pigments, herbs, seed, etc.Application In:Guar flour, tamarind kernel powder and their derivatives. Cellulose and starch derivatives, to grind pulses and cereals, chemicals, feed and minerals.

Impact Pulverizer

Get Price Quote

Impact pulverizer For guar gum & non metallic mineral pulverising, 5 standard models, Screenless pulverisers.

hammer mill pulverizer

Get Price Quote

Spice Processing Plant

Get Price Quote

Due to a vast experience and profound knowledge of the industry, we have emerged as a major Manufacturer, Supplier, and Exporter of Spice Processing Plant. It is manufactured by using the top-notch grade components and pioneering techniques. Our clients highly appreciate its robust structure, seamless finish, corrosion resistance, great performance, and long working life. It is easy to install and demands a negligible maintenance. We offer it at an economical rate.

Pin Mill Machine

Get Price Quote

WE ARE USING GRADED MATERIALS IN BITTERS AND LINERS SO IT BECOMES MAINTENANCE LESS TILL LONG TIME. OUR BITTERS, BLOWER FAN FULLY DYNEMIC BALANCED AND WE USE BEST QUALITY BEARING SO EAGLE HAMMER MILL NEEDS NO ANY FOUNDETION IN SMALL MODELS WHICH IS MOVEABLE.

salt refining plant

Get Price Quote

Since the early days, man has been using common salt as food additive in the food to improve its taste and to meet the physiological requirements of the human body. During the coarse of development of the society as man needed a wide range of materials to meet its needs it became necessary to develop range chemicals that would meet these requirements. Salt became an important ingredient and raw material for manufacture of a large number of these chemicals. Salt is reported to have over 14,000 uses. Some of the major users are

spice mill

Get Price Quote

Masala mill (spice mill) operation The materials to be ground into the crushing chamber of masala mill (spice mill) from feed hopper by gravity the beaters inside the crushing chamber accelerate the material to a very high speed to the toothed liner placed at the upper half of the crushing chamber. Shearing pulverizes the material. The ground materials through screens placed at the bottom periphery of the crushing chamber for bagging. Excess air filtered through a cotton balloon. Particle size varied using screens with different size holes. Construction of masala mill (spice mill) Masala mill (spice mill) made from heavy duty mild steel fabricated body. Aluminum grinding chamber lined with serrated wear steel plates, which protects the body from wear and tear. Grinding done by a set of fixed blades or hammers on a balanced rotor. A screen classifier forms the lower half of the grinding chamber. Application of masala mill (spice mill) Masala mill (spice mill) are exclusively meant for the grinding of chili, coriander, dry ginger, black pepper, turmeric and curry powders, rava, besan, roasted coffee seeds, sugar, ambla, mehendi, heena, herbs, salt, on a small or large scale basis. These spices are ground in a two / three stage operation, depending on the fineness desired, i.e. The breaking of the turmeric in a large hole screen for the first operation, and the subsequent fine grinding done in a fine hole screen for the second and third operation. We give here below production figures for the same. Standard accessories of masala mill (spice mill) Two numbers cotton balloons. A set of 3 numbers perforated round holes screen are supplied with the masala mill (spice mill). Ampere meter suitable totally enclosed fan cooled single or three phase sq. Cage motor is supplied with masala mill (spice mill). {electricity (special power can be accommodated): 110/220/380/415 volts, 50hz , 1/3 phase } Three meter cable along with ampere meter & suitable miniature circuit breaker for single phase motor or starter for three phase electric motor. Options of masala mill (spice mill) Magnetic feeding hopper. All contacting parts stainless steel 304 / 316 Due to continuous improvements, we reserve the rights to alter and/or amend dimensions/design without prior notice.The figure for capacities given are for guideline only may very force case to case and depending many factors.

Impact Pulverizer

350,000 Per Piece

Powder Mixing Machine

Get Price Quote

The Mass Mixer is designed for uniformly mixing of dry and wet material and especially suitable for powder of Pharmaceuticals, Food, Herbals, Agro Chemicals & Chemicals. The mass mixer consists of a rigid fabricated structure motor, gear box, mixing drum, stirrer and tilting device. Specially designed self adjusting sealing arrangement of unique design is provided to ensure that no black particle enters into the mixing drum. The material under mixing process can be monitoring through acrylic dust cover and its controls dusting and contaminations. The tilting device is provided to make easy the unloading of the material and easy cleaning of the mixing drum.

masala mixing machine

Get Price Quote

We are the manufacturer and supplier of wide range of Spices Mixer. The dimensions and configuration of the mixer are carefully balanced to provide a movement of material within the container that avoids dead spots and gives rapid product discharge. These are developed by using top quality raw material.

Chilly Grinding Machine

Get Price Quote

We are offering chilly grinding machine. Product description contraction: ms sscoating ideal for: spice & masala plant - food processing plant we are manufacturing machine as per clients requirement i.e. 50 kghr, 100 kghr, 200 kghr to 2000kghr

Spice Grinding Plant

Get Price Quote

We Ultra Febtech Pvt. Ltd. introduce Ultra Grinding Mill system - UGM mill system which is used to grind different Spices grinding like chili, turmeric, coriander etc. The Ultra Grinding mill is screen less. The system consists classifier where the fine particles of desired size are segregated. UGM mill working on Air friction base with a fan provided which cooled the material. No color changes of grounded materials; as its heats up to maximum 10-15% higher side of Room temperature. UGM mill system grinds the material with desired mesh size, hence there is no screening system required separately. We have established a note worthy status among the Ultra Grinding Mill Manufacturers in India. We bring for the clients Ultra Grinding mill of exceptional quality at cost-effective price. We have a trial facility with demo system; which will helps to suggest most suitable model from our range of products.

Pin Mill Machine

250,000 Per Piece

salt washery

1,900,000 Per unit

Sakkarpara Making Machine

180,000 Per

1 Piece (MOQ)

Impact Pulverizer

Get Price Quote

the perfect impact pulverizer meets most capacity requirements. It lend themselves to a wide degree of adjustment with finesse of the finished products ranging from about 60 mesh to bulk passing through 300 mesh depending to a considerable extent on the particular materials being handled. It combine grinding, classifying and conveying all in one single unit. it grinds with ease, economy and safety offering a wide range of particle sizing of any non-abrasive material, hard or soft from granular to finest dust up to 300 mesh. principles of impact pulverizer operation : the perfect impact pulverizer consists of and encased rotor carrying swing hammers, whizzer classifier for finess regulation and pressure gradient creator mounted on a solid shaft. Raw material from the feed hopper enters manually or automatically roll feeder and as the feeder and as the feeder pockets rotate spills into the grinding chamber. The impact to the hammers on the feed material against the liner plates reduces it into fine powder. The ground material is carried towards the wizzer classifier for clarification and the over sizw particles are rejected by the finess regulators (whizzer classifier) and returns to the grinding chamber for further grinding. Classified material is then conveyed into the cyclone for collection and bagging. A dust collector is provided in the system for ensuring dustless operation and no loss of ground powder.

Impact Pulverizer

Get Price Quote

We Ultra Febtech - An ISO 9001:2008 Certified Company Engaged in Manufucturing of Impact Pulverizer to Grind the Material.An extra heavily constructed machine designed to pulverize even rocks and minerals of medium hardness. Fineness, ranging among 100 meshes to 300 meshes (150 to 50 microns) and in some cases even 500 meshes. Non concrete foundation - frame with AVM pads may be provided. The equipment is suitable for medium hard minerals, chemicals, bulk drugs, coal, paints, dyes and pigments, herbs, seed, etc.

Turmeric grinding machinery

Get Price Quote

Impact Pulverizer

Get Price Quote

We manufacture, export and supply highly demanded Impact Pulverizer. Our Impact Pulverizer is equipped with advanced technology and is appreciated for efficiency and endurance. Our Impact Pulverizer has best quality components and demand low maintenance. Working : There are encased rotor carrying swing hammers, Blower Fan mounted on a solid shaft, and classifier. Crushing chamber is fed with the raw material through automatic rotary feeder and hopper. The constant hammer impacts convert it into the fine powder. Ground material is then taken to the classifier and the over sized particles are separated. Classified material is carried into cyclone for bagging and collection. Dust collector assures no loss of the powder. Uses : Carbon & GraphiteCoal Agricultural ChemicalsCokeCoconut Shell & Wood Saw DustClay Dye Stuff & PigmentsFerro Alloys FertilizersPharmaceuticalsDetergentsFood ProductsKathaHerbs & SpicesFillersMarine feedsMineralsPlasticsInsecticides and PesticideResins etc Specifications : A heavy duty machine to pulverize Medium hard rocks, Minerals and Chemicals.In built fan, cyclone and dust collector ensure dust free operation.Since a Screen less classifier is used, the possibility of chocking or jamming is ruled out.Adjustable feed drive with the help of standard gear box.No RCC foundation is required if fixed on a specially designed AVM pad frame.High fineness is possible from 100 mesh to 350 mesh (150 to 40 microns) and in some cases up to 500 mesh Applications : ChemicalsBulk drugsSoft and medium hard mineralsCoalPaint materialAyurvedic herbsDyes & pigmentsSeed etc Specially designed for : PlasticSpicesSaltTobaccoAyurvedic herbsMineralAgro ProductsWheatRiceMaizeCoconut shellPlaster ofPulsesParisCarbonGraphiteGypsumSoap stoneGramLime stoneCharcoalTobacco industries etc Technical Specifications ModelGrinding Chamber dia.*Power Required*Capacity Kg. / Hr.PLP-1212�5-7.5 HP40 -75PLP-1818�10-15 HP125-200PLP-2525�22-25 HP300-500PLP-3232�30-40 HP400-650PLP-3636�50-60 HP 850-1000PLP-4242�75-100 HP1000-1500PLP-4848�100-150HP1500- 2000

spice blender

Get Price Quote

We are the manufacturer and supplier of wide range of Spices Mixer. The dimensions and configuration of the mixer are carefully balanced to provide a movement of material within the container that avoids dead spots and gives rapid product discharge. These are developed by using top quality raw material. Designed with double helical ribbon agitator rotating within Based on a proven agitator construction, which provides a triple mixing action that ensure fast, efficient blending The dimensions and configuration of the ribbons are carefully balanced to ensure movement of material within the container that avoids dead spots and gives rapid product discharge Ribbon agitator for center discharge Designed for atmospheric operation

Impact Pulverizer

Get Price Quote

An extra heavily constructed machine designed to pulverize even rocks and minerals of medium hardness. Fineness, ranging among 100 meshes to 300 meshes (150 to 50 microns) and in some cases even 500 meshes. Non concrete foundation - frame with AVM pads may be provided. The equipment is suitable for medium hard minerals, chemicals, bulk drugs, coal, paints, dyes and pigments, herbs, seed, etc. Application In: Guar flour, tamarind kernel powder and their derivatives. Cellulose and starch derivatives, to grind pulses and cereals, chemicals, feed and minerals.

Impact Pulverizer

Get Price Quote

We Ultra Febtech - An ISO 9001:2008 Certified Company Engaged in Manufucturing of Impact Pulverizer to Grind the Material.An extra heavily constructed machine designed to pulverize even rocks and minerals of medium hardness. Fineness, ranging among 100 meshes to 300 meshes (150 to 50 microns) and in some cases even 500 meshes. Non concrete foundation - frame with AVM pads may be provided. The equipment is suitable for medium hard minerals, chemicals, bulk drugs, coal, paints, dyes and pigments, herbs, seed, etc.

hammer mill pulverizer

1,100,000 Per Piece

1 Piece(s) (MOQ)