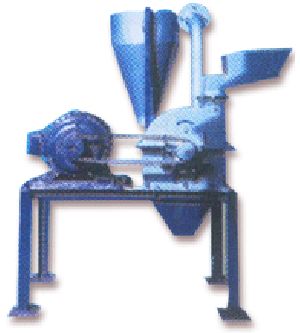

PIN MILL / SUGAR PIN MILL / SUGAR MILL MACHINE

300,000 Per Set

1 Set(s) (MOQ)

Impact Pulverizer

Get Price Quote

We are offering impact pulverizer the raw material to be pulverized enters into grinding chamber through the hopper and automatic rotary feeder. The impact of the hammer on the feed material against the liner plates reduces it into fine powder. The ground material is carried towards the whizzer classifier for classification and the over size particles are rejected by the classifier and returns to the crushing chamber for further grinding. The classified material is then conveyed into the cyclone for collection and bagging. A dust collector is provided in the system for ensuring dust free operation and no loss of ground powder advantage: impact pulverizers are most qualitative and lend themselves to a wide degree of adjustment with fineness of the finished products. In minerals and chemicals the fineness is possible from 60 to 300 meshes. Pulverisers are screen less so the possibility of chocking or jamming is ruled out. In built fan, cyclone and dust collector ensure dust free operation. Adjustable feed drive with the help of standard gear box. It has heavy duty base frame with all the ducts and pipes. application: for minerals, chemicals, china clay, dyes, pigments, saw dust, turmeric, besan, & etc.

Best Deals from Spices Processing Machinery

impact pulverizer machine

400,000 Per piece

1 piece (MOQ)

An SS (Stainless Steel) Impact Pulverizer is an industrial machine designed for grinding and pulverizing various materials into fine powders. This type of pulverizer is known for its durability, efficiency, and ability to handle a wide range of materials. Here’s a detailed overview of its design, features, benefits, and applications: How It Works: Design: The SS Impact Pulverizer consists of a stainless steel body, a high-speed rotor or impact wheel, and a grinding chamber. The rotor is equipped with impact hammers or blades that strike the material, breaking it down into smaller particles.

Impact Pulverizer

Get Price Quote

An extra heavily constructed machine designed to pulverize even rocks and minerals of medium hardness. fineness, ranging among 100 mesh to 300 mesh (150 to 50 microns) and in some cases even 500 mesh. Non concrete foundation - frame with AVM pads may be provided. The equipment is suitable for medium hard minerals, chemicals, bulk drugs, coal, paints, dyes and pigments, herbs, seed, etc.Application In:Guar flour, tamarind kernel powder and their derivatives. Cellulose and starch derivatives, to grind pulses and cereals, chemicals, feed and minerals.

Turmeric grinding machinery

Get Price Quote

Masala Making Machine

Get Price Quote

Fetch the Masala Making Machines of peerless quality from us at the rational prices. We share space with the honorable Manufacturers, Suppliers and Exporters of the Masala Making Machine from Gujarat. Useful for washing, pulverizing and mixing of spices, these high-performing Machines have 80 kg/hr to 2 ton kg/hr output capacity. Moreover, they can be purchased in diversity of models ranging 10 hp to 100 hp. Features : Easy to install Heavy duty construction Longer functional life

Spice Pulverizer

Get Price Quote

- The most suitable and convenient range to pulverize the material up to 60 - 80 mesh - A robustly constructed machine for crushing different spice, chemicals, Ayurvedic Herbs, Agro Products, etc… - We are providing as an optional AVM pad for less vibration & save cost for foundation. - Capacity Range: 25 - 1000 KG /HR. • Application: Spices, chemicals, Pigment, Coal and Agricultural Products like Gram, Maize, Rice, Husk, Sawdust, Ayurvedic herbs, Cattle Feed, Animal Feed, Poultry Feed, etc… Features of Spice Pulverizer 1. Use without cyclone and dust collector for bigger output particle size, for fine material a cyclone with dust collector is used 2. Hammer, Screen and Liners are available in different shapes and construction like hardened alloy steel, stainless steel etc., to suit the material. 3. We offered different type of material for liners and hammer as per client product for better result and best life of wear & tear part. "Fab-Tech manufactures Spice Pulverizer, Spice Mill , Masala Mill , Chilly Pulverizer , Masala Grinder, Garam Masala Pulverizer , Coriander Pulverizer , Cumin Pulverizer, Masala Grinding Machine , Masala Grinding Mill "

spices processing machinery

Get Price Quote

We manufacture, sell pulverisers, pin mill, crushers, size reduction machinery, micro pulverisers, grinding machinery, food processing machinery. Ribbon Blenders, de-seeding machine, destoners are also manufactured. Pouch Packing machine are also offered. Standard Spices processing machines are for chilly, turmeric, condiments, onion flakes, coriander, nuts, pepper etc.

Impact Pulverizer

Get Price Quote

Impact pulverizer For guar gum & non metallic mineral pulverising, 5 standard models, Screenless pulverisers.

salt washery

Get Price Quote

1 Set(s) (MOQ)

kandap machine

Get Price Quote

1 Piece(s) (MOQ)

We are offering kandap machine.

Impact Pulveriser

Get Price Quote

We are among the distinguished names in the industry for manufacturing and supplying Impact Pulveriser, which is used for the powdering of substances by means of continuous hammering in pharmaceutical, chemical, fertilizer and food processing industries. The offered pulverizer is exceptional in performance and is ideal for heavy duty. It is resistant to abrasions and is available in various specifications.

hammer mill pulverizer

Get Price Quote

Chili grinding machine

Get Price Quote

we ultra febtech pvt. Ltd. Pleased to introduce ultra grinding mill (ugm mill) system which is used to grind different spices like turmeric, chili, coriander etc. In our ugm mill system spice will be grinded in single cutting - with latest technology - controlled by synchronized control panel. Ugm mill system designed as dust proof system to reduce the loss and clean the environment. It's a close circuit condition, so it required 2 - 3 persons to operate. This system designed as cooled the material hence, no color changes / property changes in your material; ugm mill system grinds the material with desired mesh size, hence there is no screening system required separately. we already supplied the such systems for spices and running successfully till date. We are also having a trial base model of such ugm mill system at our ahmedabad based company; we are pleased to welcome you for the site visit to see the manufacturing facilities & the ugm mill and other equipments which are under manufacturing stage at our workshop.

Spice making machine

Get Price Quote

Premium Entered in spices machineries plants. About in mid - 1970. The primary function of spices in food is to improve its flavour. After rich Experiences has Determined what combination of spices should be used for a particular dish or what dictates the composition of a blend of spices know as curry powders.

Spice Pulverizer

Get Price Quote

A specially designed hammer mill with cyclone and dust collector & dust collector system. to suit spice & like materials. Fineness may be changed of screen.

Masala Pulverizer

Get Price Quote

We are one of the leading masala pulverizer manufacturers of india. The masala pulverizers we manufacture are highly reliable and of great quality. Our masala pulverizing equipments assures safety and durability.

Turmeric grinding machinery

Get Price Quote

Spices Pulverizer

60,000 Per Piece

Spice Pulveriser

Get Price Quote

A specially designed Pulveriser with cyclone and dust collector suitable for spices and material like ayurvedic herbs etc. Easily changeable screen is provided to get material of different fineness. Specially shaped ‘M’ type hammers give high production under cool condition. Pollution free working due to properly designed cyclone.

hammer mill pulverizer

1,100,000 Per Piece

1 Piece(s) (MOQ)

Impact Pulveriser

Get Price Quote

The Techno Wings brand impact pulveriser meets most capacity requirements. It lend themselves to a wide degree of adjustment with finesse of the finished products ranging from about 60 mesh to bulk passing through 300 mesh depending to a considerable extent on the particular materials being handled. It combines grinding, classifying and conveying all in one single unit. It grinds with easy, economy and safety offering a wide range of particle sizing of any non-abrasive material, hard or soft from granular to finest dust up to 300 meshes. Operating principle of impact pulveriser The techno wings impact pulveriser consists of and encased rotor-carrying swing hammers, whizzed classifier for finesse regulation and blower fan mounted on a solid shaft. Raw material from the feed hopper enters manually or automatically roll feeder and as the feeder and as the feeder pockets rotate spills into the grinding chamber. The impact to the hammers on the feed material against the liner plates reduces it into fine powder. The ground material carried towards the whizzed classifier for clarification and the finesse regulators (whizzed classifier) and returns to the grinding chamber for further grinding reject the oversize particles. Classified material then conveyed into the cyclone for collection and bagging. A dust collector provided in the system for ensuring dustless operation and no loss of ground powder. Key features of impact pulveriser Unique and reliable design The impact series pulverisers are highly effective as well as nonstop continuous pulverizing process. Compact size. Dust free operation. Ideal for dry crushing. Increased production leading to faster return on the investments. Hardened &fully machined salving type beaters thus less wears &tears. All rotating parts are dynamically balanced for reducing friction losses and noise. Standard accessories of impact pulveriser Impact pulveriser's &motor pulley Suitable numbers of cotton balloons. Anti vibrating foundation stand with adjustable rail for motor Extra accessories of impact pulveriser Suitable totally enclosed fan cooled single or three phase sq. Cage motor as per is: 325{(special power can be accommodated): 110/220/380/415 volts, 50/60 Hz ,3 phase} Suitable starters, main switch, ampere meter, capacitor for three phase V belts Contacting parts stainless steel 304 / 316 can be accommodated. Application of impact pulveriser The techno wings impact pulveriser are used for a wide range of application e.g. Agricultural, chemicals, carbon &graphite, coal, coke, coconut shell &wood saw dust, clay, dye stuff &pigments, detergents, ferro alloys fertilizers, fillers, food products, herbs &spices, insecticides and pesticides, katha, marine feeds, minerals, plastics, pharmaceuticals, resins, wheat, turmeric, bangle grams, dehydrated Onion, Dehydrated Garlic, pulses, peas, sandalwood, Snuff, etc.

Chilli Grinding Machine

150,000 - 151,000 Per Piece

impact pulverizer machine

Get Price Quote

WE ARE FIRST IN WHOLE WORLD IN THIS TYPE OF MACHINE. IN THIS MACHINE WE GIVES WIDE GRINDING CHEMBER, MAXIMUM OUTPUT IN LOWER POWER CONSUPTION, 100% JAEKETED COOLING, AUTO FEEDING, LONG LIFE BITTERS AND LINERS, NO MATERIAL BURNING, COLD OUT PUT MTERIAL, NO WEIGHT LOSS, MEXIMUM FINESS, MAINTAIN ORIGINAL TEST AND COLOUR OF OUT PUT MATERIAL, DUSTING LESS, EASY TO CLEAN, MULTI POURPOSE USE. THIS MACHINE IS MAINTAIN ORIGINAL TEST, COLOUR, FREGRANCE OF MATERIAL NO MATERIAL BURNING AND WEIGHT LOSS, YOU GET SUPERIOR QUALITY OUTPUT.

salt washery

1,900,000 Per unit

Impact Pulverizer

Get Price Quote

We Ultra Febtech - An ISO 9001:2008 Certified Company Engaged in Manufucturing of Impact Pulverizer to Grind the Material.An extra heavily constructed machine designed to pulverize even rocks and minerals of medium hardness. Fineness, ranging among 100 meshes to 300 meshes (150 to 50 microns) and in some cases even 500 meshes. Non concrete foundation - frame with AVM pads may be provided. The equipment is suitable for medium hard minerals, chemicals, bulk drugs, coal, paints, dyes and pigments, herbs, seed, etc.

Impact Pulverizer

Get Price Quote

An extra heavily constructed machine designed to pulverize even rocks and minerals of medium hardness. Fineness, ranging among 100 meshes to 300 meshes (150 to 50 microns) and in some cases even 500 meshes. Non concrete foundation - frame with AVM pads may be provided. The equipment is suitable for medium hard minerals, chemicals, bulk drugs, coal, paints, dyes and pigments, herbs, seed, etc. Application In: Guar flour, tamarind kernel powder and their derivatives. Cellulose and starch derivatives, to grind pulses and cereals, chemicals, feed and minerals.

Namak Para Making Machine

180,000 Per Piece

1 Piece (MOQ)

Impact Pulverizer

600,000 Per Piece

Impact Pulverizer

Get Price Quote

We Ultra Febtech - An ISO 9001:2008 Certified Company Engaged in Manufucturing of Impact Pulverizer to Grind the Material.An extra heavily constructed machine designed to pulverize even rocks and minerals of medium hardness. Fineness, ranging among 100 meshes to 300 meshes (150 to 50 microns) and in some cases even 500 meshes. Non concrete foundation - frame with AVM pads may be provided. The equipment is suitable for medium hard minerals, chemicals, bulk drugs, coal, paints, dyes and pigments, herbs, seed, etc.