Stainless Steel High Pressure Relief Valve

329 Per Piece

1 Piece (MOQ)

Ready To Line Valve

Get Price Quote

Best Deals from Steel Valves

Forged Steel Valve

Get Price Quote

We are well known for supplying of wide variety of Forged Steel Valve.

Stainless Steel Diaphragm Valves

9,850 Per piece

10 piece (MOQ)

3000 PSI Stainless Steel Needle Valve

380 Per Piece

50 Piece (MOQ)

Stainless steel Hydrant Valve

2,850 Per Piece

50 Piece(s) (MOQ)

Being a reliable name, we are focused towards delivering exceptional quality range, along with this, we follow strict guidelines and conduct regular quality examinations to ensure quality. We have a strong security system that helps us to make online transactions possible without getting worried about the security. You need to share your details with us and we make sure that the details are kept confidential. Features : Sturdy metal Precision made Dimensional accuracy

Stainless Steel Pinch Valve

Get Price Quote

Pinch valves, offered by our company, are the modified version of laboratory pinchcock in which rubber sleeve is protected under the casting made of cast iron. The main advantage of Pneumatic Pinch Valves is that the fluid passing from it does not come in contact with its metal parts except the sleeve. This property makes it corrosion resistive against the action of various fluids. Open Body Pinch Valves assure the smooth flow of water like pipeline and their collar sleeve eliminates gasket. Pinch valve is user friendly and can be operated easily as compared to other wheel operated valves. This valve allows positive control over flowing media because of its in between stoppage that gives desired throttling. These pinch valves are extensively used for handling corrosive slurry, liquid with solid suspensions, abrasive media, and many others. We offer pinch valve in best application range with flange as per BS, DIN, ASA & IS dimensions, and ranging between 15mm to 300mm. We are known widely as one of the proficient Pinch Valves Exporters and Suppliers. General Features & Highlights Seat Less & Glandless Valves Field Replicable Elastomer Sleeve. Elastomer Sleeve Having Four Reinforced Lugs Flanged Ends & Drilled to Din, Ansi, Bs-10, Is, Etc. this Valve Incorporates all the Design Modifications Based On Our Experience & is of Study Construction to Handle Abrasive Corrosive Media. BRIEF DETAILS OF PINCH VALVE Pinch Valve is a Seat less & Glandless valve. Pinch valve is a modified version of laboratory pinchcock. A rubber sleeve is protected under a cast iron casting. The fluid passing through do not come in contact with either body covering or any other metal parts of the valve except the sleeve. Hence the body and other metal parts are almost permanently not subjected to the corrosive action of the fluid. The flow through the valve is straight and full as that of a pipeline, when the valve is fully open. Further, the collar of the sleeve eliminates gasket. The valve is simple hand wheel operated of rising wheel type. Therefore the operation of the valve is just simple as other wheel operated valve. The in-between stoppage will allow the desired throttling. Thus the valve offers positive control over flowing media. Applications Pinch valve finds its best application in handling corrosive slurry, abrasive media, liquid with solid suspensions and many others, which are difficult to handle with seat valve. Range The flange of the pinch valve can be supplied in accordance to BS, DIN, ASA & IS dimensions The range for the valve is from 15 mm TO 300 mm. Actuation The valve can be supplied with Electrical and pneumatic actuation. <? include("other-files/pinch-valve.html"); ?> Operating Manual OF PINCH VALVE THE PINCH VALVE is a modified version of the laboratory pinchcock. A rubber sleeve is protected under a Cast iron or Aluminum split body casting. The valve is a simple hand wheel operated of rising wheel type. The operation of the valve is same as other hand wheel operated valve, it closes when moved in clockwise direction and opens when moved in anticlockwise direction. The in-between stoppage will allow the desired throttling. Thus the valve offers positive control over flowing media. The flow through the valve is same as that of a pipeline, when the valve is in fully opened condition. Further, the rubber sleeve eliminates the need of a gasket. PRELIMINARY PRECAUTION On receipt of the valve please check the position of the valve, as it is advisable to keep the valve in fully opened condition. Also check the position of the travel limit nut, if found loose then tighten the set screw of the nut. INSTALLATION The valve can be installed without any gasket unless it is required for some specific purpose. Tighten the nut of the flanges evenly & equally, but avoid too much tightening. After installation check the free movement of the upper & lower pinching bar by opening & closing the valve. The valve is then ready for the service it is installed for. MAINTENANCE If the valve is found leaking through the seat after sometime even though in fully closed condition, then set the travel limit nut by just taking it 1 or 2 threads above & then tighten. This will allow more room for traveling of rubber sleeve & ensure the valve to zero leakage. This problem sometimes occurs when the sleeve is slightly worn out, when used under abrasive condition. Further, The Rubber sleeve of the valve up to 2 (50mm) have a single lug on either side and it goes into the hollow passage of the pinching bar where it is fixed with the lug clamping screws. In the higher sizes above 2 the sleeves have two lugs on either sides and is fitted overlapping the pinching bar. DISMANTLING THE VALVE & REPLACING THE RUBBER SLEEVE When the rubber sleeve is ruptured or totally worn out then it is to be replaced with a new one. In this case first dismantle the valve by following the instructions. Remove the hand wheel. Open the Tie Bar nuts. Disconnect the spindle from the Horseshoe connection and remove it completely with the bridge. REMEMBER not to temper the set screw of the yoke bush, unless if required it should be completely tight. Open out the nuts & bolts of the split body of the valve. Remove the screw of the lugs from both the pinching bars. Now fit the new rubber sleeve & reverse the operation to assemble the complete valve. NOTE It is advisable to keep a spare rubber sleeve for maintenance purpose, considering the self life of the Rubber as six months when packed & stored in dark. The Pinch valves should be stored in fully open condition only. We also offer complete spares of the valves, but request you to place your order a week in For more details please click on the links given below

Forged Steel 3 PC Design Ball Valve

340 Per Piece

1 Piece (MOQ)

steel gate valves

1,200 Per Piece

5 Piece (MOQ)

Stainless Steel Ball Valves

300 Per Piece

Our investment in the well-structured warehouse has paid off well. We have successfully installed up-to-the-minute warehouse management software to keep the entire lot in a safe and organized manner. From the point of view of marketing, shipping, and handling, our products are securely packed in top-grade supplies using ultramodern packaging machines. The packaging is extremely reliable.

Forged Steel Gate Valves,Globe Valves,Chake Valves

Get Price Quote

We are offering forged steel gate valves,globe valves,chake valves moc :- a105,f304,f316,lf2 size :- to 2” pressure :- up to 2500 class end conection :- s/e & f/e.

Forged Steel Flanged Piston Check Valves

1,900 Per Piece

1 Piece (MOQ)

Forged Steel Globe Valve

Get Price Quote

We are offering forged steel globe valve, jupiter controls valves forged steel globe valves are bolted bonnet, outside screw and yoke type, rising spindle construction. Jupiter controls forged valves body and bonnet made from high quality forgings. Jupiter controls offer forged steel globe valves in size 12” (dn15) to 2” (dn50) to suit various critical, non-critical applications and pressure rating in 800 class. Jupiter controls forged steel globe valve manufacturing range covers regular port and standard port both types of valve. Regular port globe valves have fast delivery or ready stock, for standard port globe valve do manufactuing on order basis. Jupiter controls offer forged steel globe valve in wide range of body materials like astm a 105 - forged carbon steel, astm a 182 f 304304l316316l - forgated stainless steel 304304l316316l, astm a 182 f 1122 - alloy steel to suit industrial application. Jupiter controls forged steel globe valves are available under any third party inspection also. For high pressure & temperature application stellited f6 face seat & disc available. Forged globe valve available is threaded end, socket weld end, butt weld end and flanged end connection. For flanged end forged steel globe valve flanges will be a welded with a valve body not integral forged manufacturer & exporter of wide range of industrial forged steel globe valves rising stem forged steel globe valve (regular port) rising hand wheel, bolted bonnet forged globe valve (regular port)

forged steel lift check valve

1,000 Per Piece

01 Piece(s) (MOQ)

Forged Steel Gate Valve

Get Price Quote

Forged Steel Valves Forged Steel GateGlobeNon-Return Valves are for high pressure applications have compact design and are manufactured as per API 602 and are perfect for small Pipelines up to 50NB. They come with a choice of Threaded or Socket Weld ends. The Hard Faced Trim material guarantees faultless Sealing and durability. They are perfectly machined and are provided with a Lapped Back Seat in case of Gate and Globe types so that the Gland Packing in stream can be replaced andor repacked; when the Valve is in full open position so that it is highly safe, and cost-effective.

Forged steel valves

Get Price Quote

Forged steel valves, Industrial Forged Steel Globe Valve, Forged Steel Gate Valve, Forged Steel Check Valves & Forged Steel Ball Valve in Regular (Reduced) and Standard Bore (Full bore) with Screwed End, Socket Weld End & Butt Weld (Welded Neck) End Connection.J D Ball Valves are also available with different type of Seat, Seal & Packing material such as P.T.F.E. (Virgin) Glass Filled P.T.F.E. Carbon Filled P.T.F.E. Graphite (Grafoil) PEEK to suit special requirement of client.

Cast Steel Globe Valve

Get Price Quote

We are the leading exporter and supplier of this products.

Forged Steel Globe Valve

Get Price Quote

Nivz Valves Forged Steel Globe Valves are Bolted Bonnet, outside screw and yoke type, Rising Spindle construction. Nivz Forged Valves Body and bonnet made from high quality forgings. Nivz Valves & Automation manufacturer and exporter Forged Steel Globe Valves in size 1/2” (DN15) to 2” (DN50) to suit various critical, non-critical applications and pressure rating in 800 and 1500 class. Nivz make Forged Steel Globe Valve manufacturing range covers Regular Port and Standard Port both types of Valve. Regular Port globe valves have fast delivery or ready stock, for Standard Port globe valve do manufactuing on order basis. Nivz manufacture Forged Steel Globe Valve in wide range of Body Materials like ASTM A 105 - Forged Carbon Steel, ASTM A 182 F 304/304L/316/316L - Forged Stainless Steel 304/304L/316/316L, ASTM A 182 F 11/22 - Alloy Steel to suit high temperature and pressure industrial application. Forged Steel Globe Valves are available under any Third party inspection also. For High Pressure & Temperature application Stellited F6 Face Seat & Disc available. Forged Globe Valve available in Threaded End (BSP / NPT Female), Socket Weld End, Butt Weld End, Weld Neck End and Flanged End Connection. For flanged end connection Forged Steel Globe Valve flanges will be a fabricated / welded with a valve body, flanges are not integral forged with body. A complete range of Forged Steel Globe Valve Manufacturer, A 105, F11, F22, F304L, F316L Material Forged Valve Exporter, Stockist, Supplier, Importer. Application Generaly fine controlling of flow Power Plants & Process Industries Petrochemical Plants & Refineries Fertilizers Plants Process & General Industries Sugar Industries & Distillery Plants Water, Steam, Gas, Oil & other Non-aggressive media Other application on request Salient Features of Globe Valve Body & Bonnet made from high quality forging. The Forgings are precision machined for high performance Leak Proof Body-Bonnet Joint With Spiral Wound Gasket Ground Finish Stem Self Aligning Two Piece Gland Back seating feature facilitates repacking of the stuffing box on line with the valve in fully open position.

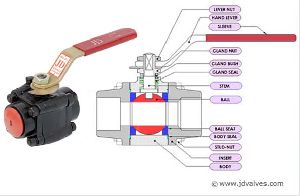

FORGED STEEL HIGH PRESSURE BALL VALVE

Get Price Quote

J. D. Controls manufacturing High performance Forged Steel Ball Valve as per international design and standard to get 100% Client Satisfaction and repeat order with total interchangeability, superior quality, workmanship & service. These Ball Valves come in Three Piece Design (1/2 to 2) to suit various critical, non-critical applications and pressure rating up to 800 class in regular (reduce) bore design. J D P.T.F.E. seated Forged Steel Ball Valve gives Zero Leakage, Tight Shut-Off and Low Torque with easy smooth operation at temperature ranging from -20° C. to +220° C. Electro-Polished, Buff Finish & Ultra clean valve also provided for Food & Pharmaceutical Industries on request. WIDE RANGE OF BODY SEAT, SEAL & PACKING: J D Ball Valves are also available with different type of Seat, Seal & Packing material such as P.T.F.E. (Virgin) / Glass Filled P.T.F.E. / Carbon Filled P.T.F.E. / Graphite (Grafoil) / PEEK to suit special requirement of client. DESIGN & TESTING INTERNATIONAL STANDARD: Valve Design : BS 5351 / ANSI B 16.34 Pressure Testing : BS 6755 Part II / API 598 Face To Face : ANSI B 16.10 Butt Weld End : ANSI B 16.25 Socket Weld End : ANSI B 16.11 Screwed End : ANSI B 1.20.1(BSP/NPT) SALIENT FEATURES: High Performance Ball Valve Longer Life Positive Shut off Quick in Action No Lubrication Compact Design Low Pressure Drop Simplicity

Stainless Steel Ball Valve

800 Per Piece

Stainless Steel Valves

1,000 Per Piece

We are the leading supplier of this products.

Forged steel valves

Get Price Quote

Forged Stainless Steel Valves compact design GateGlobeNon-Return Valves are manufactured in a wide-ranging materials like Forged Carbon Steel in compliance to A105, Forged Alloy Steel like LF2, F11, F22; F51 and Forged Stainless Steel like F304, F304L, F316 and F-316L. The sizes available are from 10NB through 50NB and pressure rating from ASME 800# through 2500#.

Stainless Steel Needle Valves

Get Price Quote

We offer high quality SS Needle Valve at very affordable market price. These needle valves are manufactured using very high quality raw material and very skillful workers. These can be tailor made according to the specification provided by the customers. These products are in great demand in critical environments such as petrochemical, fluid power, electronics, process machinery and other major industrial applications.

Stainless Steel Ball Valve

Get Price Quote

Stainless Steel Ball Valve, Pulsation snubber, pressure snubber, Gauge Cocks

Stainless Steel Butterfly Valves

Get Price Quote

We are an acclaimed manufacturer of a qualitative range of Stainless Steel Butterfly Valves to our highly reputed clients. They find application in various industrial sectors to fit their diverse requirements. These valves are made up of tested quality stainless steel at our unit along with the help of latest machinery and technology.

cast steel valve

Get Price Quote

cast steel valve, cast iron, Cast Iron Valve, Casting Product

Stainless Steel Valves

Get Price Quote

Stainless Steel Valves, Stainless Steel Pipe, Copper Materials

Stainless Steel Ball Valve

Get Price Quote

Stainless Steel Ball Valve, PTFE Lined Ball Valves, ceramic ball valves

Stainless Steel Valves

Get Price Quote

Stainless Steel Valves, Cast Iron Valves, mild steel industrial valves

industrial steel valves

Get Price Quote

industrial steel valves