SIDE SUCTION PUMP

Get Price Quote

1 Piece (MOQ)

Application Filter press feeding Effluent treatment plant Dyes & intermediates Steel rolling mills Slurry transter Ceramic. ETP & STP Paper and pulp, sugar & food. Features Single stage semi open impeller. Special design for filter press application Reduce gland leakage. Heavy duty shaft. sleeve & bearings Noise & maintenance free High efficiency low power consumption Grease I oil lubricant bearings Only positive (+V) suction head.

Horizontal Side Suction Pump

31,000 - 62,000 Per Unit

5 Piece (MOQ)

Best Deals from Suction Pump

Rubber Lined Pump

Get Price Quote

10 Piece (MOQ)

Features : Construction : All wet parts coming in contact with liquid pumped are either lined on cast Iron or made appropriate corrosion resistance Non-Metalics. Drive : Pumps are mainly arranged from a coupling drive or V belt drive on request Impeller : Semi-Open type rubber lined Impeller handles maximum solid particles without load on pump's Efficiency Shaft : EN-9 OR SS 316 Sleeve : Alloy-20, Ceramic, FRP Ball Bearing : Inboard bearing is pressed on shaft (En-9 / SS 316) and is free to float axially in frame which carries radial load only. Outboard bearing is shouldered red and locked on shaft with locknut and washer and in bearing housing to carry radial and any unbalanced thrust load. All bearing fits are precision bored. Gland Packing : Pumps are fitted with gland packing compatible with the liquid to be handled. Applications : Hydraulic Acid at all Concentrations Dilute Sulphuric Acid Pigment Slurries Lime Slurry / Milk of Lime Phosphoric Acid Solutions Paper Stock Industrial effluents Ore Slurries Acidic Slurries Abrasive Slurries Sea Water

Multistage Closed Couple Bottom Suction Submersible Water Pump

Get Price Quote

Fully stainless steel construction multistage submersible enbloc bottom suction electric pump WSM is best suitable for application of “Pressure boosting system”, “Rain Water Supply”, “Water supply from tanks, basin, river or 5” or above bore well. The “DRY” motor is protected by double mechanical seal with an interposed oil chamber provide long lasting reliability. Motor cooled by pumped liquid passing between the motor body and the external jacket is a supplementary advantage.

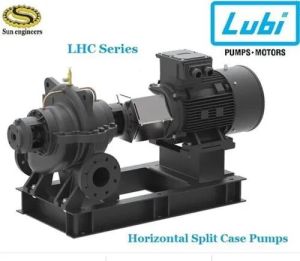

Horizontal Split Casing Pumps

Get Price Quote

We are a prominent Horizontal Split Casing Pumps Manufacturer and Supplier in India. These Horizontal Split Casing Pumps are horizontal axially split casing, single stage, double suction or single suction, single volute or double volute type pumps with horizontal shaft. The Horizontal Split Casing Pumps can be availed from us at the most competitive prices. These are horizontal axially split casing, single stage, double suction or single suction, single volute or double volute type pumps with horizontal shaft. Special Features : Rotating assembly accessible for inspection or maintenance by removing upper half casing without disturbing suction and delivery piping and motorHorizontal execution ( standard ) or vertical execution ( optional)Vertical pump, direct drive or with universal shaft arrangementHigh hydraulic and overall efficiency due to superior design and manufacturing techniquesGood suction performance and low NPSHStable characteristics, minimum maintenance required, vibration free performanceHigh reliability Pump Casing : Horizontal axially spilt volute type, suction and discharge nozzles and supporting feet are cast integral with lower half casing. Impeller : Double or single suction type accurately balanced. In case of double suction impellers, the hydraulic thrust is balanced automatically because of pressure equalization on both sides of the impeller. Shafts : The high tensile steel shaft accurately machined and ground is supported by antifriction bearings. The shaft is protected by shaft sleeves from wear in stuffing box area. Stuffing Box : Can be sealed by gland packing or by mechanical seal and is suitable for liquids having temperature up to 90oC. Bearings : Grease Lubricated deep groove ball I roller bearings are provided. Large pumps can be provided with Oil Lubricated / Oil ring bearings. Direction Of Rotation : Standard : Anticlockwise ( ACW ) when viewed from driving endOptional : Clockwise ( CW ) when viewed from driving end Drive : Suitable for coupling with electric motors, engines or steam turbines either directly or through belt drives, gear boxes etc. Flanges : Standard : Drilled to BS : 10 Table D/E/F or BS-4504,Table PN16 plain face depending upon modelOptional : DIN / ASA with suitable pressure rating depending upon model

horizontal split case pump

Get Price Quote

End Suction Pumps

14,500 - 26,500 Per Piece

1 Piece (MOQ)

SANITARY PUMP CFS SP SERIES

Get Price Quote

creative engineers now introduce self priming cum centrifugal pump with closed and semi open impeller. • we have made ss-304 or ss-316 chamber in round shape or in square shape . • these chambers are interconnected with casings , casings have flap type or disc type non return valve (nrv) depend upon application . We use flap type nrv when liquid is dirty or containing some solid particles . We use disc type check valve when liquid is crystal clear. • these nrvs hold liquid in the chamber and centrifugal pump work as self priming pump. • all wetted parts are made from ss-304 or ss-316 sheet only and chambers are tested with hydraulic test up to 10 bar . If pressure is more , then we test at 1.5 times then shutoff pressure thickness of sheet depend upon size and pressure of system . • these pumps are ideal for all application where people do not want to use foot valve and have suction problem. • size of self priming chamber depend upon capacity and suction length . We also offer openable chamber so one can clean it very easily. This is required in sanitary application and in some sticky material application . • all our cf series pumps are now available with such chamber in monobloc or bare version. • all our mud pumps which is very costly in ss castings are now offered in our new spcf version with open or semi open impellers .

Sanitary Centrifugal Pumps

25,000 Per Piece

We are offering sanitary centrifugal pumps. With the valuable assistance of our skilled team of professionals, we have been able to come up with a wide range of ss centrifugal pumps. We make use of the optimum quality raw material with the latest technology to manufacture these pumps. Due to the remarkable quality of the offered range, we have successfully attained the position of the market leader in this domain. reliable engineers are expertise in manufacturing of centrifugal pumps, design of pump is sturdy and parts are with long life, manufacturers & exporters stainless steel centrifugal pumps, special features: pumps are fabricated type from rolled sheet horizontal centrifugal pumps with close semi- open open type impeller design less maintenance due less rotating parts. safe and quite operation levels. suitable for standard motor or flange type or foot cam flange type motor also available in bare and mono block pump flame proof mono block are also available according to requirement different connection are available like dairy connection, tri clover connection, flange end connection, nipple connection economic, efficient & easy in maintenance moc : ss-304ss316ss316l application: ideal for handling of water, dmdi water, mineral water, hot water, pharmaceuticals liquid drugs & syrups, milk, butter milk, soft drink, beverages, solvents, acids, alkalis, light petroleum products etc. acid and light chemicals, color dyes and pigments booster application water treatment plants, r o plants manufacturer & exporters centrifugal bare pumps

horizontal split case pump

Get Price Quote

horizontal split case pump

42,669 - 355,412 Per Piece

1 Piece (MOQ)

suction pumps

27,000 Per Piece

Rubber Lined Pump

Get Price Quote

AMTRL – SERIES RUBBER LINED PUMP ARE USEFUL FOR HANDLING ACIDIC AND ALKALINE MATERIAL IN INDUSTRIES » APPLICATION › CAUSTIC SODA, BRINE, HYDROFLUORIC ACID, AMMONIUM SALT SOLUTION, BLEACHING SOLUTION › EFFLUENTS, CALCIUM HYPOCHLORITE, POTASSIUM CHLORIDE, SODIUM CHLORINE, ZINC CHLORIDE, › PHOSPHORIC ACID, NITRIC ACID, DYES & CHEMICALS WITH FREE CHLORINE, SODIUM BISULPHATE, › MOTHER LIQUOR, AMMONIA SOLUTION, CHLOR – ALKALI ELECTROLYSIS, DEMONIZED WATER, RIVER WATER, › FILLER PRESSURE FOR DYES, SEA WATER, LIME PUMP IN CPW PLATE, STAPLE FIBER PLANT (BLEACH LIQUOR), › DILUTE H2SO4 WATER TREATMENT, CYCLONE FEED, COAL & POWER PLANT ASH, ABRASIVE SILT, › RIVER-BED GRAVEL, FLY ASH SLURRY, IRON ORE SLURRY, COPPER OX CHLORIDE POTASSIUM HYPOCHLORITE, › SUSPENSION WITH FINE ABRASIVE SOLID » SPECIAL FEATURES › CENTRIFUGAL SINGLE STAGE BACK PULL OUT DESIGN. › CONTACT PARTS ARE LINED WITH NATURAL RUBBER (EBONITE), BUTYL RUBBER OR NEOPRENE RUBBER. › SIMPLE EXTERNAL AXIAL ADJUSTABLE FOR IMPELLER ADJUSTMENT. › SIMPLE AXIAL ADJUSTABLE TO MAINTAIN IMPELLER CLEARANCE. › POWER INPUT 3 HP / 5 HP / 7.5 HP / 10 HP / 15 HP / 20 HP WITH 940 RPM / 1440 RPM / 1880 RPM / 2200 RPM › CAPACITY UP TO 125 M3/H AND 35 MTRS HEAD › PUMP IS MOUNTED ON HEAVY STEEL STRUCTURE FRAME (BASE PALTE) › PUMP IS WELL ALIGNED WITH ELECTRIC MOTOR BY RIGID COUPLING › BETTER INTERCHANGEABILITY OF PARTS › EASY MAINTENANCE › STURDY CONTRACTION

centrifugal end suction pump

25,000 Per Set

1 Set(s) (MOQ)

JBCSP Series We offer Thermic Fluid Pumps. These are single stage end suction back pull-out type centrifugal pumps with following specifications: Operating data: Capacity : up to 1100m3 /hr Head : up to 150 mtrs. Size : 25 mm to 300 mm. Temperature : 350o C Speed : 1450/2900 rpm 50hz 1150/1750/3500rpm 60hz Pressure : up to 15 Kg/cm2 M.O.C : C.I,C.S.,SS-304/304L SS 316/316 L ,Bronze ,Alloy-20,CD4MCU,Hast alloy B C etc Features: Moduler construction high interchangeability ,fast delivery Versatile shaft sealing arrangement glands packing as a standard arrangement and option to use mechanical seal Back pull out design enabling easier removal for inspection and maintenance Process type design results in minimum downtime Closed impellers ensures high efficiency for along period operation Pump comes in three bearing design resulting in good continuous process with high productivity Bigger shaft and bearing size enabling sturdy design Application: Hot and cold water circulation cooling water circulation Drip irrigation water supply and building services Thermic fluid, jet dyeing, volatile fluids, heat exchanger Condensate handling, fire fighting system, environmental engineering ,marine refrigeration and cooling tower installation etc Chemicals petrochemicals pharmaceuticals, refineries, steel plant, sugar,paper, laminates industries, textiles, rubber, handling of hydrocarbons, organic and inorganic chemicals, D.M water, food industries, salt plants, power plants and in industries such as pulp ,fertilizers and other process industries etc Additional Information: Minimum Order Quantity: 1 Piece

centrifugal end suction pump

15,000 Per Piece

End Suction Pump

Get Price Quote

Side Suction Centrifugal Pump

Get Price Quote

We are successfully ranked as the notable Manufacturer, Exporter and Supplier of Side Suction Centrifugal Pump from Ahmedabad, Gujarat, India. The Side Suction Centrifugal Pumps, we offer, are fabricated using the top of the line quality materials and the latest technology. Energy efficiency, high performance, user friendly operations and low maintenance are some of the highlights of our Side Suction Centrifugal Pumps. For rock bottom prices, contact us.Specifications : Series : SFP Series Type : Side Suction Centrifugal Pump (With semi-open Impeller) Operating Range : Capacity : up to 75 m3/hr Head : up to 95 mtr Pressure : up to 10 kg/cm2 Size : 40 mm to 65 mm Speed : up to 2900 rpm Temp : up to 150 C M.O.C. : CI, CS, SS304 / 316, SS 304 L/316L, Alloy 20, Hast alloy B or C,CD4MCU, etc. Applications : Slurry Transfer, Chemical process, Transfer, Filter press feeding, Effluent handling, Minerals Process Ind., Spra

End Suction Centrifugal Process Pump

55,125 - 278,250 Per Piece

Design Features Horizontal Centrifugal, Back-Pull-Out type pump fitted with single stage closed Impeller in foot mounted Volute Casing having axial end suction and Vertical centerline delivery. Designed to confirm DIN 24256 / ISO 2858 / API 610 (in general). Applications : Cooling, Heating, Circulating, Boosting, Air Conditioning, Refrigeration And Cold Storage Systems Agriculture usage such as General Irrigation, Sprinkler Irrigation and De-watering systems. Civil usage such as water supply schemes for Buildings, Hotels & Commercial Complexes. To handle clean as well as moderately aggressive liquids.

End Suction Pump 50 Hz

Get Price Quote

LES are single-stage End-suction pump according to ISO 2858. Our range also includes several models of pumps which have been developed with duty condition which are not covered in ISO 2858. The volute casing of End suction pump is designed to be robust in construction to take the undue stresses offered by the pipe work. They have an axial suction port and radial discharge port. Standard flanges are PN 16 as per DIN standard EN 1092-2 and PN 25 as per DIN standard EN 1092-2. ANSI 125 and ANSI 250 as per ASME B16.1 are available on request Water Supply. Pressure boosting for high rise buildings, hotels industry etc. Industrial washing & cleaning systems. Fire Protection systems. Cooling & Air Conditioning systems. Boiler feed and condensate transfer system. Irrigation systems for fields including sprinkler & drip irrigation systems. The pumps are non self priming horizontal end suction pumps with axial suction port and radial discharge ports. Standard flanges for suction and discharge ports will be PN 16 as per DIN standard EN 1092-2, PN 25 as per DIN standard EN 1092-2, ANSI 125 and ANSI 250 as per ASME B16.1 are available on request. Performance and dimensions comply to ISO 2858. These pumps are close coupled pumps with TEFC squirrel cage induction motors with main dimensions complying to IEC standards. These pumps are available with mechanical shaft seal only. These pumps have the discharge range from 3 to 660 m³/hr and head range from 4 to 158 meters. Motor ratings are from 0.37 to 132 kW. The pump impellers are dynamically balanced to grade 6.3 of ISO 1940. These pumps are available with our standard range of motors complying with EFF2 motors. They can also be supplied with EFF1 motors on request.

End Suction Pumps

Get Price Quote

End Suction Pumps

25,000 Per Piece

1 Piece (MOQ)

Horizontal Centrifugal End Suction Pumps

Get Price Quote

Noise and maintenance free High efficiency hydraulic design Back pull out design Conform to iso 2858 dimensions Suitable with V-belt drive or direcct coupled with a motor. Heavy duty shaft, sleeve and bearings Low NPSH Single and double mechanical seal Steady head and capacity One roller bearing on pump end, two angular contact ball bearing with oil lubricated. Serveral flange drilling options according to valid standards.

horizontal split case pump

25,000 Per Piece

Horizontal Split Casing Pump

Get Price Quote

Applications and Industries: Water supply Building Services Circulating Water Systems Paper Mills Water / Effluent Treatment Pharmaceuticals Irrigation Sugar Mills Ports and Docks Vegetable Oil Mills Air Conditioning General Industry Requirements Fire fighting Options and Features: Horizontal and vertical Execution and Centre Line Suspension Gland Pack / Mechanical Seals 3 stage HSC Pump with Head up to 170 mtrs and flow up to 350 m3/hr for Condensed Extraction. Bush Bearing arrangement Bearing Cooling arrangement High head pumps have Double Volute Casing Two stage pump-single entry closed type with Impellers Back to Back Metallurgy:- Cast Iron / Bronze Combination CF-8M / CA6 NM Combination Ductile Steel and other special Metallurgles

Zero Suction Multistage Pumps

Get Price Quote

We have developed "UNEEL" brand zero suction vertical Submersible Pumpsets, in the rage of 3HP/2.2KW to 25HP/8.5KW. The advantage of this zero suction vertical pump is that it can lift water at 6" water level whereas other Pumpsets work up 5' to 6' water level. Applications:Sump, Basement, Mines & CollieriesPerformance Table: Zero Suction Vertical Monoset - Stage: 1 to 5 - H.P.: 3 to 25

Cast iron split case large scale water pumps

Get Price Quote

Single Stage Suction Pump

20,000 - 22,000 Per Piece

Rubber Lined Slurry Pump

20,000 - 25,000 Per Piece

End Suction Back Pull Out Pump

Get Price Quote

We specialize in specially designed End Suction Back Pull Out Pumps that are popular in the market because of its high efficiency volute type casing. The Casing of End Suction Back Pull Out Pumps and its suction and discharge nozzle as well as the supporting feet are cast integral with the casing. It also has an enclosed type impeller which is accurately and dynamically balanced with balancing holes & back vanes. Our Pump also has shaft made from tensile steel that ensure consistent performance of the pump. Specialty Shaft made from tensile steelSuction and discharge nozzleHigh efficiency volute type casingBalancing holes & back vanes. Widely used in ChemicalTextileFertilizerPaper & PulpPetrochemicalFood ProcessingSugarStarchRefineryPowder PlantDairyPharmaceuticalOil Extraction etc.

End Suction Pumps

Get Price Quote