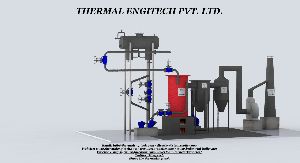

Vertical Thermic Fluid Heater

585,000 - 1,895,000 Per Units

Vertical Thermic Fluid Heater is brought afore by us especially for solid fuel fire. Its design is innovative and its functioning is high. It is examined thoroughly, leaving no scope for imperfections or flaws. Plus, it is safe and economically priced, making it value for money. We are bracketed with the chief Manufacturers, Exporters, and Suppliers of Vertical Thermic Fluid Heater from Gujarat, India. We export Thermic Fluid Heater to vairous countries and have esteemed customers in more than 22 countries across the globe. Salient Features : 3-Pass Design for Solid Fuel Firing Package/Factory assembled unit. Safe & Economical Efficiency of 78+2%

Type : Thermic Fluid Heater

Material : Alloy Steel, Metal

Certification : CE Certified

Application : Industrial

Weight : 100-1000kg, 1000-2000kg

Feature : Double Chamber, Durable, Easy Installation

Automatic Grade : Automatic

Driven Type : Electric

Motor Power : 1-3Hp, 3-6Hp

Temperature : 100-150°C, 150-200°C, 200-250°C

Fuel : Wood / Coal / Agro Waste / Etc.

...more

VERTICAL 4-PASS THERMIC FLUID HEATER

1,100,000 - 7,500,000 Per Units

1 Piece (MOQ)

vertical four pass thermic fluid heater is combustion grate that gives you an assurance of the rated output on any solid fuels like coal, wood, lignite, husk, briquettes, pet coke, saw dust, bagasse, etc. without compromising on performance & efficiency. this reduces downtime leading to further increase in profitability.every solid fuel has different physical and chemical properties which influences the design and performance of the furnace in thermal fluid heater. different combustion systems are shown in above diagrams.low grade fuels are best handled using fbc technology to give good results. thermal's unique design for efficient combustion suits different solid fuels like coal, lignite, wood, husk, pet coke, bagasse and biomass fuels resulting in to low operating cost, trouble free operation and lesser maintenance husk, agis best suited for some fuels with high ash content like low grade coal, paddy ro wastes etc.fbc technology ensures complete combustion, helps homogeneous mixing of fuel, maintains uniform bed temperature and leaves low un-burnt fuel guaranteeing 5 to 7% higher efficiency than any other combustion system.options of in-bed tubes in furnace is also available to control bed temperature & system performance.fluidized bed combustion technology is best suited for fuels like low grade coal, imported coal, paddy husk, petcock, etc with auto feeding system of over bed & under bed into furnace. salient features: multi fuel fired system cost efficient unit also with latest fbc system automatic firing of solid fuel as similar to oil & gas capacity:200,000 to 10,000,000 kcal/hr. temperature:upto 400©c fuel:coal / wood / lignite / paddy husk / petcock / saw dust / bagasse / palm oil extracts / etc.

Material : Mild Steel

Automatic Grade : Automatic, Manual, Semi Automatic

Application : Industrial

Feature : Fully Insulated, Stable Performance

Country of Origin : India

...more

Vertical 4 Pass Thermic Fluid Heater

1,000,000 - 8,100,000 Per SET

1 SET (MOQ)

We are engaged in making obtainable performance-oriented Vertical 4 Pass Thermic Fluid Heater to the global market. We are associated with the league of #1 Manufacturers, Exporters, and Suppliers of Vertical 4 Pass Thermic Fluid Heater from Gujarat, India. Our products are appreciated for being highly efficient, durable and affordable. Details : Vertical Four Pass Thermic Fluid Heater is combustion grate that gives you an assurance of the rated output on any solid fuel like coal, wood, lignite, husk, briquettes, pet coke, saw dust, bagasse, etc. without compromising on performance & efficiency. This reduces downtime leading to further increase in profitability. Every solid fuel has different physical and chemical properties, which influences the design and performance of the furnace in Thermal Fluid Heater. Different combustion systems are shown in above diagrams. Low-grade fuels are best handled using FBC technology to give good results. Thermal's unique design for efficient combustion suits different solid fuels like coal, lignite, wood, husk, pet coke, bagasse and biomass fuels resulting in to low operating cost, trouble free operation and lesser maintenance husk, agis best suited for some fuels with high ash content like low grade coal, paddy ro wastes etc. FBC technology ensures complete combustion, helps homogeneous mixing of fuel, maintains uniform bed temperature and leaves low un-burnt fuel guaranteeing 5 to 7% higher efficiency than any other combustion system. Options of In-Bed Tubes in Furnace are also available to control bed temperature & system performance. Fluidized Bed Combustion Technology is best suited for fuels like low grade coal, imported coal, paddy husk, petcock, etc with Auto feeding system of Over bed & Under bed into Furnace. Salient Features : Multi Fuel Fired System Cost Efficient Unit Also with Latest FBC System Automatic Firing of Solid Fuel as similar to Oil & Gas

Type : Thermic Fluid Heater

Material : Alloy Steel

Certification : CE Certified

Application : Industrial

Weight : 100-1000kg

Automatic Grade : Automatic

Motor Power : 1-3Hp, 3-6Hp

Feature : Double Chamber, Durable, Easy Installation

Temperature : 100-150°C, 150-200°C

Temperature : upto 400©C

Fuel : Coal / Wood / Lignite / Paddy Husk / Petcock / Saw Dust / Bagasse / Palm Oil Extracts / etc.

...more

V-THERMIC FLUID HEATER

1,000,000 - 8,100,000 Per SET

1 SET (MOQ)

3-Pass Vertical Design Thermic Fluid Heater is a special design for Solid Fuel Fire. Salient Features: 3-Pass Design for Solid Fuel Firing Package/Factory assembled unit. Safe & Economical Efficiency of 78+2%

Temperature : upto 400°C

Fuel : Wood / Coal / Agro Waste / etc.

...more

V-4-PASS THERMIC FLUID HEATER

1,000,000 - 8,100,000 Per SET

1 SET (MOQ)

Vertical Four Pass Thermic Fluid Heater is combustion grate that gives you an assurance of the rated output on any solid fuels like coal, wood, lignite, husk, briquettes, pet coke, saw dust, bagasse, etc. without compromising on performance & efficiency. This reduces downtime leading to further increase in profitability.Every solid fuel has different physical and chemical properties which influences the design and performance of the furnace in Thermal Fluid Heater. Different combustion systems are shown in above diagrams.Low grade fuels are best handled using FBC technology to give good results. Thermal's unique design for efficient combustion suits different solid fuels like coal, lignite, wood, husk, pet coke, bagasse and biomass fuels resulting in to low operating cost, trouble free operation and lesser maintenance husk, agis best suited for some fuels with high ash content like low grade coal, paddy ro wastes etc.FBC technology ensures complete combustion, helps homogeneous mixing of fuel, maintains uniform bed temperature and leaves low un-burnt fuel guaranteeing 5 to 7% higher efficiency than any other combustion system.Options of In-Bed Tubes in Furnace is also available to control bed temperature & system performance.Fluidized Bed Combustion Technology is best suited for fuels like low grade coal, imported coal, paddy husk, petcock, etc with Auto feeding system of Over bed & Under bed into Furnace Salient Features: Multi Fuel Fired System Cost Efficient Unit Also with Latest FBC System Automatic Firing of Solid Fuel as similar to Oil & Gas

Temperature : upto 400©C

Fuel : Coal / Wood / Lignite / Paddy Husk / Petcock / Saw Dust / Bagasse / Palm Oil Extracts / etc.

...more

Three Pass Thermic Fluid Heater

We have expertise in designing Three Pass Thermic Fluid Heater with the use of industry-grade components. The Three Pass Thermic Fluid Heater is fabricated utilizing the advanced techniques, and thus increases the overall outcome while reducing the downtime. Also, the 3-Pass Vertical Design Thermic Fluid Heater is a special design for Solid Fuel Fire. Salient Features 3-Pass Design for Solid Fuel Firing Package/Factory assembled unit. Safe & Economical Efficiency of 78+2%

Type : Thermal Fluid Heaters

Material : Alloy Steel

Certification : CE Certified

Application : Industrial, Machinery

Weight : 100-1000kg

Color : Brown

Feature : Double Chamber, Durable

Automatic Grade : Automatic

Power Source : Thermal Power

Motor Power : 1-3Hp, 3-6Hp

...more

Thermic Fluid Heaters

Solid fuel fired 3-pass thermic fluid heater with standard accessories, thermic fluid pump with motor.

...more

Thermic Fluid Heater

HORIZONTAL OIL FIRED THERMIC FLUID HEATER 3-Pass Horizontal Design Thermic Fluid Heater has excellent fuel efficient Unit. Salient Features: High Efficiency : 87+2% on LCV of Fuel. High unit dependability reducing down time and thereby maintenance costs. Maximum reliability of operation leading to high productivity. Prompt service & spares back up. Capacity:1,00,000 kcal/hr. to 30,00,000 kcal/hr. Temperature:upto 400°C Fuel:Oil / Gas Burner:Two Stage / Three Stage / Modulating Pressure Jet Fully Automatic High Fuel Efficient IMPORTED Burner

...more

THERMAL-SIB SMALL INDUSTRIAL BOILER

775,000 - 890,000 Per Units

fully automatic, instant steam generating range of boilers designed for safe and reliable operations. easy to install and commission, these time-tested boilers require very little maintenance. it features a specially designed furnace and combustion system to burn difficult heavy oils and offers fuel flexibility between light and heavy oils to help respond to fluctuating fuel prices. salient features: high efficiency. large steam & water volumes. less maintenance unique patented membrane design built-in heat recovery device membrane design allows large tube diameter for coil enabling better steam dryness, less frequent de-scaling, longer coil life and minimum downtime unique economiser - optimiser design ensures maximum heat recovery without possibility of feed water pump failure due to boiling/ vapour causing cavitations and pump failure unique circulation burner design prevents leakage and eliminates fire hazard ceramic wool refractory allows fast cooling of top plate and easy maintenance easy access to all parts requiring maintenance. capacity:500 kg./hr. to 850 kg./hr. pressure:10 kg/cm2 to 20kg/cm2 fuel:coal / wood / lignite / petcock

...more

4 - Pass Solid Fuel Fired Thermic Fluid Heaters

1,200,000 - 15,000,000 Per Unit

1 Set(s) (MOQ)

vertical 4-pass thermic fluid heater: vertical four pass thermic fluid heater is combustion grate that gives you an assurance of the rated output on any solid fuels like coal, wood, lignite, husk, briquettes, pet coke, saw dust, bagasse, etc. without compromising on performance & efficiency. this reduces downtime leading to further increase in profitability. every solid fuel has different physical and chemical properties which influences the design and performance of the furnace in thermal fluid heater. different combustion systems are shown in above diagrams. low grade fuels are best handled using fbc technology to give good results. thermal's unique design for efficient combustion suits different solid fuels like coal, lignite, wood, husk, pet coke, bagasse and biomass fuels resulting in to low operating cost, trouble free operation and lesser maintenance husk, agis best suited for some fuels with high ash content like low grade coal, paddy ro wastes etc. fbc technology ensures complete combustion, helps homogeneous mixing of fuel, maintains uniform bed temperature and leaves low un-burnt fuel guaranteeing 5 to 7% higher efficiency than any other combustion system.options of in-bed tubes in furnace is also available to control bed temperature & system performance. fluidized bed combustion technology is best suited for fuels like low grade coal, imported coal, paddy husk, petcock, etc with auto feeding system of over bed & under bed into furnace. salient features: multi fuel fired system cost efficient unit also with latest fbc system automatic firing of solid fuel as similar to oil & gas capacity:600,000 to 10,000,000 kcal/hr. temperature: normal case upto 300 deg. c & in special case upto 400 deg. c fuel: coal / wood / lignite / paddy husk / petcock / saw dust / bagasse / palm oil extracts / etc.

Brand Name : Thermal

Country of Origin : India

Power Source : Solid Coal, Multi Fuel

Automatic Grade : Automatic,Manual,Semi Automatic

Color : Red & Black

Application : Industrial,Machinery

Certification : ISO

Material : Mild Steel

Type : Solid Fuel Fired Thermic Fluid Heaters

Condition : New

Weight : 0.2 Million kcal./hr. to 10 Million kcal./hr.

Feature : 4-Pass

Temperature : 200-250°C,250-300°C,300-350°C, 350-400 deg. C

...more

THERMAL-MAX

550,000 - 6,500,000 Per Set

1 Set(s) (MOQ)

3-PASS FULLY WET BACK STEAM BOILER Thermal-Max Steam BoilerSmoke tube type system boiler with three pass fully wet back design, suitable for cal / agro waste / oil / gas fuel. Salient Features: Factory-assembled horizontal package boiler. Less site work & quick commissioning Suitable for coal, wood & briquetted fuel. Manual firing - less complexity. Large integral furnace - minimum heat loss. High turn-down ration. End to end visibility of tubes. Easy access for inspection & cleaning. Quick and easy ash removal. Low excess air burners, imported / indigenous.

Type : Industrial Boiler

Certification : IBR / ISO

Weight : 2000 kg to 35000 kg

Color : Red & Black

Voltage : 380V, 440V.540V

Fuel Type : Biogas, Gas, Diesel , Bio-Diesel

Condition : New

Boiler Capacity : 0-2Tph, 2-4Tph, 4-6Tph, 6-8Tph

Working Pressure : 0-250Psi, 250-500Psi

Brand Name : Thermal

Specialities : Horizontal 3-Pass Fully Wet Back

Boiler Capacity : Oil Fired - 500 kg./hr. to 8000 kg./hr.

Working Pressure : 10 kg./cm2 to 35kg./cm2

...more

THERMAL COMBI BOILER

1,500,000 Per Set

5 TO 10 Set(s) (MOQ)

Products COMBI DESIGN BIOMASS BOILER: A unique design of the pre-furnace consists of lateral wall made of finned tube connected to the boiler body through headers. Salient Features: Complete gas-tight construction. Greater absorption of radiant heat. Fast water circulation resulting in accelerated start up and better boiler response to load fluctuations. Designed to give full load efficiency upto 80%. Optional FBC System for Capacity above 5000 kg./hr. for Automatic Firing.

Type : Combi Boiler

Material : Mild Steel

Certification : ISI Certified, IBR

Application : ETC.

Color : RED AND BLACK

Voltage : 380V, 440V.540V

Condition : New

Capacity : 0-2Tph

Power : 15 KW

Pressure : 0-250Psi

Brand Name : THERMAL

Style : MEMBRANE WATER WALL COMBI BOILER

Fuel : COAL, WOOD, SAW DUST, BRIQUETTES, ETC.

Application : INDUSTRIAL

Color : RED & BLACK

...more

Steam Boiler - Small Industrial Boiler

We are Offering Steam Boiler. type: Package capacity: 300 Kg. Hr. to 600 Kg.hr. steam Temperature: 7 Kg.hr. we Do Complete Turnkey Job

...more

Steam Boiler - Membrane Type

1,000,000 - 20,000,000 Per Piece

1 Piece (MOQ)

We Offer Membrane Type Water Wall Boiler. capacity: 500 Kg./hr to 35 Tone/hr. temperature: 100 Psi to 500psi fuel: Multi Fuel manual / Fbc.

...more

Steam Boiler

1,000,000 - 10,000,000 Per Piece

1 Piece (MOQ)

We are the major manufacturer, exporter and supplier of superior quality Steam Boilers. The Steam Boilers provided by us are developed using the latest technology and are robustly constructed. The usage of high quality raw material ensures the ruggedness and durability. Our Steam Boilers are low on maintenance and economic. Product Details Membrane Type Water Wall BoilerCapacity : 500 kg/hr to 35 tone/hrTemperature : 100 psi to 500psiFuel : Multi FuelManual / FBC

Application : industrial

...more

solid fuel steam boiler

We offer heavy duty Solid Fuel Steam Boiler in the market. It is a Smoke tube type system boiler with three pass fully wet back design, suitable for coal, wood, briquette, lignite, and growaste. Salient Features Factory-assembled horizontal package boiler. Less site work & quick commissioning Suitable for coal, wood & briquetted fuel. Manual firing less complexity. Large integral furnace minimum heat loss. High turn-down ration. End to end visibility of tubes. Easy access for inspection & cleaning. Quick and easy ash removal. Low excess air burners, imported / indigenous.

Type : Solid Fuel Boiler

Material : Metal

Certification : CE Certified

Weight : 200-400kg

Color : Multi Colour

Driven Type : Fuel

...more

Solid Fuel Fired Thermic Fluid Heaters

675,000 Per Set

1 Set(s) (MOQ)

3-PASS VERTICAL SOLID FUEL FIRED THERMIC FLUID HEATER WITH STANDARD FITTINGS AND ACCESSORIES.

Type : Solid Fuel Fired Thermic Fluid Heaters

Material : Mild Steel

Certification : ISO

Application : Industrial

Weight : 2 LAC KCAL TO 10 LAC KCAL.HR

Color : Red & Black

Feature : Fully Insulated

Automatic Grade : Automatic, Manual

Temperature : 100-150°C, 150-200°C, 200-250°C, 250-300°C

...more

Small Industrial Boiler

1,000,000 - 10,000,000 Per Piece

1 Piece (MOQ)

We manufacture small industrial boiler from 100 kg./hr. To 800 kg./hr. With working pressure 3 kg./cm2 to 10.54 kg./cm2.

Brand Name : BMS

...more

Pressure Reducing Valve Stations

We offer high-quality Pressure Reducing Valve Stations to various industries, engaged in the steam system management, across the globe. We are enlisted with the chief Manufacturers, Exporters, and Suppliers of Pressure Reducing Valve Stations from Gujarat, India. These pre-fabricated valve stations, we offer, are ready to install units. They are made available in custom configurations. The inlet and outlet piping’s and valve’s size is precisely established. And the entire pipe work and fittings are accurately dimensioned so that the control valve is confronted with requisite pressure drop only.

Type : Fixed

Material : Cast Iron

...more

Pressure Reducing Valve Station

200,000 - 2,500,000 Per SET

1 SET (MOQ)

We are offering pressure reducing valve station. These pressure reducing valve stations provided by us offer high performance and durability due to the incorporation of high grade metal as the raw material in the production process. Our pressure reducing valve stations demand low maintenance and are cost effective. product details : we provide : complete prv station with ibr form iiic capacity : 500 kg.hr to 40 tonehr technical specifications : on demand industries : sugar paper oil chemical plywood food pharma textile any industry where heat steam is required

...more

oil thermic fluid heater

1,000,000 - 10,000,000 Per SET

1 SET (MOQ)

HORIZONTAL OIL FIRED THERMIC FLUID HEATER 3-Pass Horizontal Design Thermic Fluid Heater has excellent fuel efficient Unit. Salient Features: High Efficiency : 87+2% on LCV of Fuel. High unit dependability reducing down time and thereby maintenance costs. Maximum reliability of operation leading to high productivity. Prompt service & spares back up. Capacity:1,00,000 kcal/hr. to 30,00,000 kcal/hr. Temperature:upto 400°C Fuel:Oil / Gas Burner:Two Stage / Three Stage / Modulating Pressure Jet Fully Automatic High Fuel Efficient IMPORTED Burner

...more

Oil Steam Boiler

1,000,000 - 10,000,000 Per Piece

3-PASS FULLY WET BACK STEAM BOILER Thermal-Max Steam Boiler Smoke tube type system boiler with three pass fully wet back design, suitable for cal / agro waste / oil / gas fuel. Salient Features: Factory-assembled horizontal package boiler. Less site work & quick commissioning Suitable for coal, wood & briquetted fuel. Manual firing - less complexity. Large integral furnace - minimum heat loss. High turn-down ration. End to end visibility of tubes. Easy access for inspection & cleaning. Quick and easy ash removal. Low excess air burners, imported / indigenous. Capacity:Oil Fired - 500 kg./hr. to 8000 kg./hr.

...more

oil gas fired thermic fluid heater

1,000,000 - 10,000,000 Per SET

1 SET (MOQ)

We are offering oil gas fired thermic fluid heater. Fully automatic oilgas fired horizontal thermic fluid heater with standard accessories.

...more

Oil Fired Steam Boiler

1,000,000 - 10,000,000 Per SET

1 SET (MOQ)

We are offering oil fired steam boiler. package type 3 pass fully wet back steam boiler capacity: 1000 kg.hr. To 8000 kg.hr. With working pressure of 10.54 to 21 kg.cm2 with suitable imported burner for firing ldo, fo, diesel and natural gas

Application : Liquid Boiling

Material : Mild Steel

...moreOpening Hours