shot blasting

Shot blasting process at TKT Hightech Cast is equipped with machines from Indabarator (NESCO) & Electro Magnetic in which an abrasive material is forced through a jet nozzle using compressed air. This creates a fast and effective way of cleaning or preparing surfaces for recoating using steel shots. Steel shots are sharp, hard abrasive which is used to prepare surfaces on non‐ferrous metals before recoating. TKT Hightech Cast has installed shot blasting wire mesh type with online capacity of 800 kg.

...more

Sand Plant

The company is in the process of installing a 40 ton capacity sand plant from EIRICH. The sand preparation plants have PLC controlled systems and prepare moulding sand by a fully automated process in order to get high surface quality. This sand plant will encompass components like: Intensive mixer Pre blender Rotary drum polygon sleeve Casting / Sand cooler Automatic additive dosing system Online compactability controller Centralized PLC based controls

...more

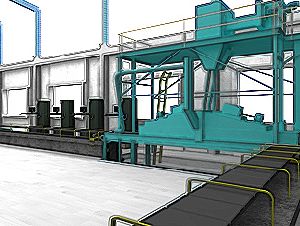

Molding Plant

The process of making any high quality casting begins with a high-quality mould. This concept is clearly embodied in the technology planned for producing moulds; the company is installing a double station, high pressure (Aeration), Flask-Less Moulding Line - FCMX 2 from Sinto Japan. The high pressure flask less moulding line with horizontal parting will produce a mould with size 508mm X 601mm X 200mm and at mould rate of 200 nos / hr. The bunch weight of the cast product will range from 25kgs to 35kgs with average yield of 70%. The Benefits The benefits of Flask-Less moulding include improved casting quality, uniformity, high density moulds, and high output of products, excellent surface finish & reduced labor. Flask-Less moulding will also provide reduced air consumption, rapid core setting, easy inspection of cores, reduced finishing time and quick pattern changes. The moulding line will also ensure perfect repeatability and precision of all moulding parameters.

...more

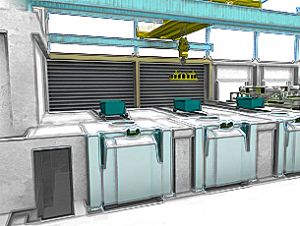

Melting Plant

TKT Hightech Cast will be installing a state of the art CI & SG Iron Melting Plant of 1500 MT a month backed by 2000 kg x 3 Crucible Tri Track Induction Melting Furnace from Inductotherm with a capacity of 5 tons / hour melting. This technologically advanced induction equipment is of high accuracy, will provide the users precision, control and reliability in all their needs.

...more

investment casting machine

Casting Machine market Global. Identify growth segments and opportunities for investment. Benchmark performance against key competitors; The key details related to Die Casting Machine Market like the product definition, cost, variety of applications,

...more

Fettling Machine

Cast has implemented a full-service manual finishing operation to grind and finish your castings products to your exact requirements. By providing in-house finishing shop, we control the process from casting to finishing. Our grinding finishing shop floor is equipped with the state of the art grinding and finishing equipment, to provide the best finished quality products, with best finished surface finishes.

...more

Fettling

For finished cast parts, fettling is very important to ensure that the parts work properly. Hybrid Fettling Machines are being installed at TKT Hightech Cast which includes machines from NESCO. The shot blasting process at TKT is being equipped with machines where abrasive material is forced through a jet nozzle using compressed air. Other finishing processes at TKT Hightech Cast include manual grinding with number of world class grinding machines for finishing of castings. TKT Hightech Cast has planned to implement a full-service of manual finishing operation to grind and finish your castings products to exact requirements. The grinding finishing shop floor will be equipped with the state of the art grinding and finishing equipment, to provide the best finished quality products, with best finished surface finishes. Grinding & Finishing TKT Cast has implemented a full-service manual finishing operation to grind and finish your castings products to your exact requirements. By providing in-house finishing shop, we control the process from casting to finishing. Our grinding finishing shop floor is equipped with the state of the art grinding and finishing equipment, to provide the best finished quality products, with best finished surface finishes. Production Possibilities List of Auto components which can be produced at TKT Hightech Cast will be required as it will help create more focus in the marketing and production approach

...more

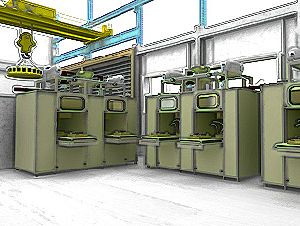

Core Making

The Core making facilities at TKT Hightech Cast have been setup to offer its customers the perfect balance of precision & economy via utilization of the right type of core for every specific product through extensive facilities like: Cold box core shooters Shell core shooters No bake core making facility Core coating and drying facility A core shop with cold box & shell core facilities will be equipped with two machines with cold box process to match moulding line requirements with one machine that consists of shell back process to match production consistency along with the moulding lines.

...more

casting plant

For finished cast parts, fettling is very important to ensure that the parts will work properly.Hybrid Fettling Machineries from Indabarator & Electro Magnetic have been installed along with Hybrid Vibratory Shake Out Machine

...more

Cast Iron Casting

Cast Iron Product

Motor Body

mounting casing

Sg Iron Casting

sg iron products

Be first to Rate

Rate ThisOpening Hours