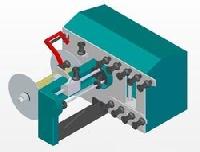

Trim Winder

Get Price Quote

Catering to the customers' needs with excellence, we are engaged in offering high quality lot of Trim Winder. In order to settle the financial transaction with our clients through the transfer of monetary value, we offer diverse options including online and offline payment procedures.

Trim Winder Machine

120,000 Per Piece

5 Piece(s) (MOQ)

We are offering Trim Winder Machine

Best Deals from Trim Winder Machines

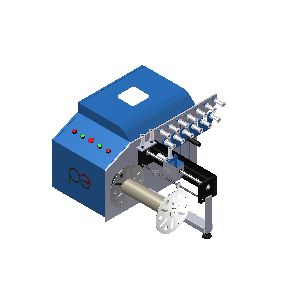

Trim Winder Machine

Get Price Quote

Trim winders incorporate many features for high reliability of trim winding. It's an valuable concept to add the value by rewinding and processing the trim produced By converting machines, like slitting, Extrusion, pouch making and many more... Typical Specifications: Trim width: 5 to 50 mm Web thickness: 10µm to 1 mm Package diameter: 300 mm Package width : 300 mm Core diameter : 100 mm Maximum Speed : 600 m/min

winder machine

Get Price Quote

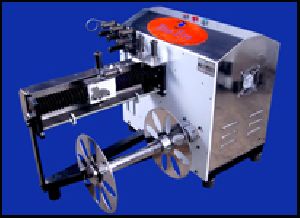

Trim Winder

140,000 - 145,000 Per Piece

Trim Winder Machine

Get Price Quote

Riding on unfathomable volumes of industrial expertise, we are providing a broad array of Trim Winder Machine. Features: Superior functionality Long functional life Less power consumption

Trim Winder

175,000 - 200,000 Per piece

1 Piece (MOQ)

Trim Winder Machine

Get Price Quote

Trim Winder Machine

Get Price Quote

Our Trim Removal System – TRIM WINDER MACHINE is simple equipment using latest technology, to help you manage the trims effectively and efficiently for better profitability. Technical Specification BLUE EYE Trim winders incorporate many features for high reliability of trim winding. The precision electromechanical traversing system is maintenance free with operator control of the traversing rate which remains constant regardless of the line speed or the spool diameter. This, together with the inbuilt pineapple winding technology, ensures optimum winding of the trim and therefore increases the reliability. The lightweight web guide roll assembly traverses for high speed operation with the spool running in a fixed position. Each trim winder is driven by its own variable speed motor running under closed loop tension control from a precision dancer. Alternatively, where space is at a premium, the winder motor can be operated under direct torque control. Full sized rolls can be unloaded quickly and the winder restarted.Winders are fitted with a remote air inflation system on winding shafts for paper cores or a quick release mechanism on shafts. Standard Features Optional Fully mechanical controlled traversing. Trapezoidal (Pineapple) winding profile. Cantilevered winding shaft. Closed loop speed control. Traverse winding. Variable traversing rate. Quality engineered and manufactured. Save your Electricity. Keep your floor clean. Pull roll for constant pull during roll change. Winding to minimize waste. Winding of 2 trims on one winder. Winded roll use for making rope. Operation The motion control drive is controlled by a digital inverter drive, capable of both driving and stopping the motor. Material is fed by dancer for tension control, equipped with a position feedback through ultrasonic sensor. Together with the PID controls on the trim winder control board, this provides a speed reference for the motion control drive. The system operates to maintain the dancer in a fixed position, thus providing static rewinding tension. The tension is set by the position of the dancer. When the dancer is close to the refrence, the trim tension is high. When it’s furthest away from the refrence, the tension is low. Dancer position is set by the internal set tension in tourqe mode. The dancer is mounted on a cross travel mechanism, and acts as a layering guide to the trim. The cross travel is controlled by a lead motion liner guide ways with automatic end reversing, so that dancer always rotates in motion control. The traverse motor is controlled by a digital inverter drive operating directly from the AC supply. A setpoint isolator on the control board links the winding motor speed reference with the traverse motor so that they operate in unison. The winder can either be stopped and started from the remote control push buttons or linked directly to the main feed machine. A trim break detector on the control operates three seconds after start up to stop the winder if the dancer hasn't been pulled off its end stop position.

Trim Winder Machine

Get Price Quote

Doctoring Rewinding Machine, W cut punching machine, Dry Lamination Machine

Trim Winder

Get Price Quote

Cloth Grinding Machine, Plastic film industries, Industrial Tires

Trim Winder Machine

Get Price Quote

Hydraulic Web Guiding Systems, Chasing Web Guiding Systems, Safety Chucks

trim west winder.

Get Price Quote

trim west winder., rewinder system, unwind stand, unwinder system

Trim Winder Machine

Get Price Quote

Bopp Tape Coating Machine, vmch coating machine, Cantiliver Slitting Machine

Trim Winder

Get Price Quote

Roto Gravure Printing Press, center slitting machine