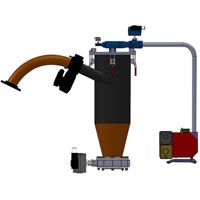

vacuum transfer system

Get Price Quote

Design is cGMP – Current Good Manufacturing Practices compliance. All contact parts AISI 316 & non contact parts AISI 304. Capacity available 100 Kg to 5000 Kghr. Can be used for transfer of products having bulk densities up to 1.0gmcc. Total Discharge no Retention. No segregation or degradation of Product. No tool required for opening & cleaning. Transfer can be completely automatic to avoid the manual handling of the material Fully automatic system, with timing controls and automatic air blow back system for filter cleaning. Vacuum Blower and cyclone filter can be installed in out side production area. Avoids product waste, loss and contamination. Easy to clean and wash of contact parts. Option for Inline Milling, Sifting with Blender and Loading material to RMG, Tablet press& Vessel.

vacuum transfer system

Get Price Quote

Vacuum tablet press loading systems are furnished as complete, ready-to-operate systems for mounting on customers’ presses. Available for single or dual hopper tablet presses The loader eliminates manual scooping of product and messy dumping or mishandling. Draw material directly from drums, boxes, storage containers, process vessels.Thus Vacuum Loading reduces the manual labor intensity,to eliminate the dust pollution to ensure the production line with GMP.

Best Deals from Vacuum Transfer System

Vacuum Transfer Systems

Get Price Quote

he conventional vacuum charging system is a sophisticatedly designed system that makes the use of IPC, which minimizes the overall amount of handling. It works on the principle to move different types of material that can be pulled by a hose or a tube. Some of the main components of conventional vacuum charging system include, blower, vacuum receiver system with filter, cyclone filter and a pipe. Specialized in different kinds of material transfer processes Characteristic features Parts configured with SS 316 material mainly Filters made specially with non woven fabric and washable material Filter assembly and collection port covered with toggle clamp which minimizes the use for cleaning Saves manpower Time based convey cycle and discharge cycle in vacuum transfer systems Manual handling available that fosters saving of wastage of material Incorporated butterfly valve for the purpose of easy discharge Effective process and unit operation feed Used extensively in pharmaceutical industry, food and chemical industries. Timer based vacuum transfer system with timely updates on the system Minimized segregation available in the powder vacuum system Personal safety ensured in the vacuum transfer system Flexible in installation and user friendly conventional vacuum charging system An enclosed system that controls cross contamination Easy maintenance due to less moving components Sequential timer based system with four operation cycles Advanced control systems that make the operation more convenient A finely equipped vacuum safety valve for safety considerations Control panel made with SS 304 material, configured with dust proof construction

vacuum transfer system

Get Price Quote

vacuum transfer system, Rotary Tablet Compression Machine

Vacuum Transfer Systems

Get Price Quote

Vacuum Transfer Systems, Bottle Air Jet Vacuum Cleaning Machine

vacuum transfer system

Get Price Quote

vacuum transfer system, air jet cleaning machine, Packing Conveyor