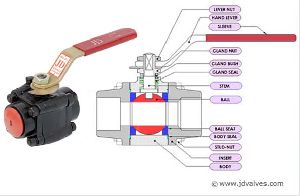

FORGED STEEL HIGH PRESSURE BALL VALVE

Get Price Quote

J. D. Controls manufacturing High performance Forged Steel Ball Valve as per international design and standard to get 100% Client Satisfaction and repeat order with total interchangeability, superior quality, workmanship & service. These Ball Valves come in Three Piece Design (1/2 to 2) to suit various critical, non-critical applications and pressure rating up to 800 class in regular (reduce) bore design. J D P.T.F.E. seated Forged Steel Ball Valve gives Zero Leakage, Tight Shut-Off and Low Torque with easy smooth operation at temperature ranging from -20° C. to +220° C. Electro-Polished, Buff Finish & Ultra clean valve also provided for Food & Pharmaceutical Industries on request. WIDE RANGE OF BODY SEAT, SEAL & PACKING: J D Ball Valves are also available with different type of Seat, Seal & Packing material such as P.T.F.E. (Virgin) / Glass Filled P.T.F.E. / Carbon Filled P.T.F.E. / Graphite (Grafoil) / PEEK to suit special requirement of client. DESIGN & TESTING INTERNATIONAL STANDARD: Valve Design : BS 5351 / ANSI B 16.34 Pressure Testing : BS 6755 Part II / API 598 Face To Face : ANSI B 16.10 Butt Weld End : ANSI B 16.25 Socket Weld End : ANSI B 16.11 Screwed End : ANSI B 1.20.1(BSP/NPT) SALIENT FEATURES: High Performance Ball Valve Longer Life Positive Shut off Quick in Action No Lubrication Compact Design Low Pressure Drop Simplicity

Pressure Free Powder Butterfly Valve

Get Price Quote

We are the leading exporter and supplier of this products.

Best Deals from Gate Valves

Gate Valves

Get Price Quote

Salient Feature Meets design requirement of ASME B 16.34 / API 600 / API603 /API 6D and testing requirement API 598 / BS 6755 / API6FA / ISO 5208 Outside Screw and Yoke Construction Valves provided with back seating arrangement Solid, flexible, split wedge and parallel slide are available Renewable, seal welded seat ring or integral seat ( Cast SS. only ) available. Specially designed die formed graphite packing, controlled clearance between stem, gland and bonnet bushing for guaranteed low emissions meet 100 PPM maximum fugitive emission levels. Anti - friction ball thrust bearing in yoke sleeve for higher size and classes Grub Screw : Secures yoke nut in the bonnet Gress Nipple : Supplies lubricant to the mating parts Flanged End or butt welding end Flanged end dimensions conform to ANSI / ASME B 16.5 / API 605 / DIN / BS 3293 Butt welding end dimensions conform to ANSI / ASME B 16.25 Face to Face and End Dimensions conform to ASME / ANSI B 16.10 / DIN / BS 2080 Bi - directional shut-off. Option Extended bonnet provided for low temperature and cryogenic services (cold box and non cold box applications) to conform to requirement of BS-6364 Deep stuffing box - with lantern ring Self - aligning two piece gland Gear Box / Chain Wheel design available Electric or pneumatic actuator design available Ring joint facings available in higher classes Locking arrangement optional By-Pass, Drain Plug design available Stellited seating hard facing are provided on request Alloy-20, Monel, Hstelloy B & C, CF3 & CF3M Materials on request Application Petrochemical Industries Pharmaceutical Plants Oil Industries Petroleum Refinery Power Plants Thermal & Gas Fertilizers & Agro Chemicals Steel Plant Paper Industries Cement Industries Cryogenic Services

Pressure Reducing Valve

302 Per Piece

1 Piece (MOQ)

Knife Edge Gate Valves

3,200 - 125,000 Per Piece

1 Piece (MOQ)

Metflow Engineers is reliable and trusted Knife Edge Gate Valve manufacturer in India. Metflow Engineers manufacturing uni-directional knife gate valves and bidirectional knife gate valves a wide range of knife gate valve manufacturers in different models and several different sizes of knife gate Valves using high grade of CI / WCB / SS304 and SS316 knife gate valves casting to the suite to every specific application are honoured as the finest one and has become an obvious choice in the user industries. Our Knife Edge Gate Valve is one of the specific designs to ensure minimum contact between the parts of the valve to reduce Wear & Tear. The Batten edge of the Gate (Knife-Edge) allows the tight shut-off even when solid particles settle at the bottom of the Body. Contact us today.

Spring Loaded Non Return Valve

Get Price Quote

10 Piece (MOQ)

High Pressure Needle Valve

380 Per Piece

50 Piece (MOQ)

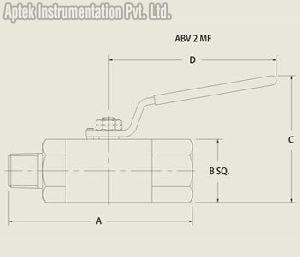

ABV 2 MF High Pressure Ball Valve

Get Price Quote

Snubber valve

Get Price Quote

1000 Piece (MOQ)

Brass Drain Plugs

Get Price Quote

We bring forth the best quality Brass Drain Plugs for our prestigious customers. The Brass Drain Plugs made available by us are widely acclaimed for their robust construction, accurate design and reliable performance. We stock the plugs in our large warehouses to cater to bulk requirements of the buyer easily. Our company is an eminent Supplier of Drain Plug Brass from Ahmedabad, Gujarat and known for our fair pricing policy.

Gate Valves

Get Price Quote

We manufacture a wide range of Gate Valves which include knife gate valves, cast iron gate valves and flangled gate valves. These valves are renowned all over for their premium quality. With the quality assurance we are the largest flanged gate valves supplier in India. We also manufacture these gate valves according to customer specifications. The quality of these valves is intact. They are properly inspected and verified before sending them to client. Uses of acme quality metal and flawless designs which enhance the performance of these valves have made us stand much ahead from the other manufacturers in India. Gate Valves are Outside Screw & Yoke, Bolted bonnet & with Rising stem. The STRAIGHT THROUGH BORE design assures minimum turbulence, erosion and resistance to flow caused by pockets & recesses. Gate Valves are mainly used where minimum pressure drop is a requirement. However, they can not be used for THROTTLING SERVICE because half open Gate Valves can damage the Seat Rings. Gate Valves are always used either in full open or full closed position. Design Features : Designed for exceptionally low pressure drop Back seating arrangement permits the replacement of packing with valve under fully open condition. Two piece design of gland flange provides centralizing effect to the gland sleeve, thus producing a uniform clamping pressure on the packings. Material Structure : End Connection : Flanged end raised face, Butt weld end, RTJ, etc. Operation : Hand wheel, Gear operator, Electrical Actuator, Pneumatic, Hydraulic Shell :WCB, WC1, WC6, WC9, LCB, LCC, LC3, C5, C12, CF8, CF8M, CF3, CF3M, CF8C, CN7M, CD4MCu, Hastalloy, Inconel, Duplex Stainless Steel Trim :13% Cr. Steel, 304, 304L, 316, 316L, 321, 347, Monel, Duplex Stainless Steel Standards " Design Standard : API 600 Testing Standard : API 598 Face to Face : ASME B 16.10 End Connection : Flanged End : ASME B 16.5 Butt Weld End : ASME B 16.25 Pressure Temperature : ASME B 16.34 Valve Operation : Operator : Hand Wheel : Size Range : 2-10 Class 150, 300, 600 2-4 Class 900 & 1500 Operator : Gear Operator Size Range : 12 & above Class 150, 300, 600 6 & above Class 900, 1500

Gate Valve

Get Price Quote

1 Piece (MOQ)

Sluice Gate Valve

10,000 - 10,500 Per Piece

Gate Valve

Get Price Quote

Knife Edge Gate Valve

1,810 Per Piece

5 Piece (MOQ)

Gate Valves

Get Price Quote

Since 22 years, we are manufacturing gateglobecheckballnrvstrainer valves. We are supply this material in all over the india.

steel gate valves

1,200 Per Piece

5 Piece (MOQ)

Gate Valves

Get Price Quote

Non-Rising Gate Valve Flange End Size: 1'' to 12'' Pressure: 150#; 300# M.O.C.: C.I.; WCB; S.S.304; S.S.316 End Connection: Flange suits to ASME B16.5

Gate Valve

1,600 Per pices

10 Piece (MOQ)

Gate Valve

2,000 Per Piece

10 Piece (MOQ)