Liquid Vial Packaging Line

Get Price Quote

1 Piece (MOQ)

vial liquid packaging line | injectable liquid filling line manufacturer and exporter in india vial liquid packaging line is suitable for 2 ml to 10 vials with up to 400 vials per minute output speed. complete injectable vial filling line | vial line the complete injectable vial liquid filling line consists of an automatic rotary vial washing machine/ linear vial washing machine, sterilization and depyrogenation tunnel, automatic vial filling and rubber stoppering machine, automatic vial aluminum/flip off capping machine, online visual inspection conveyor, automatic vial sticker labelling machine, automatic vial cartoning machine etc. with the speed up to 400 vials/minute. we offer customized solutions per customer requirements. automatic rotary vial washing machine/ automatic linear vial washing machine sterilization & depyrogenation tunnel automatic vial filling and stoppering machine automatic vial cap sealing machine automatic premium vial sticker labelling machine with 21 cfr system automatic vial cartoning machine why harikrushna machines' liquid vial packaging line is the 1st preference of every pharma company? iso 9001:2015 and ce-certified injectable vial packaging line manufacturer and exporter high-quality vial liquid packaging line at a reasonable cost. prompt and the best pre-and-post sales services. more than 12500 machine installations spread to more than 60 countries international regulatory standards, including who, gmp, cgmp, usfda, mhra, tga, ema, tras, cfia, and fsms

Six Head Vial Liquid Filling Machine

100,000 - 500,000 Per piece

1 Piece (MOQ)

Best Deals from Vial Filling Machine

Automatic Vial Filling And Bunging Machine

1,500,000 Per piece

1 piece (MOQ)

Injectable Vial Filling Machine

250,000 - 1,575,000 Per Piece

1 Piece (MOQ)

Vial Filling and Plugging Machine

Get Price Quote

Ampoule and Vial Filling Machine

Get Price Quote

We are one of the most renowned and well established companies which are also offering its clients one of the finest quality ampoule and vial packing machines. These ampoule and vial packing machines are one of the most efficient and reliable kind of machines which we are not only manufacturing but also are efficiently supplying in different parts of the country. These ampoule and vial packing machines are used for the purpose of packing the medicines and drugs in most efficient and convenient manner. We are offering these ampoule and vial packing machines to our clients at a very reasonable range of prices. Features: Easily affordable Long lasting Easy to use and maintain Low consumption cost Supreme construction

VOLUMETRIC VIAL BOTTLES FILLING MACHINE

Get Price Quote

Automatic volumatric vial bottles filling machine is working on the volumetric principle. The machine consists of diving nozzles. The machine is made up of stainless steel matt finish body. It is compact and versatile. HOW IT IS SIMPLE AND QUICK : There is a twin pneumatically operated stopper system with feed below and filling nozzles. The conveyor belt moves the container to the filling nozzles. The reciprocating nozzles and stopper system can match for centering of the container below nozzles, to avoid the wastage of the liquid. The nozzle goes upwards from the bottom level to minimize the foaming. The fill size can easily set with a hexagonal bolt, below the syringe. THE FEATURES : Very much accurate, ±1% filling accuracy. Vibration free construction Error code display The platform is provided with drain tray round it, and drip tray under the conveyor The perfect pneumatic arrangement for bottle stopping The conveyor gear box, motor and pneumatic cylinders are provided with the safety guard. To prevent from the short circuit and over load, the MCB is given. For the voltage fluctuation and short circuit in A/C frequency drive there is inbuilt protection, with machine No bottle no filing system Trouble free performance with low maintenance Easy control panel Low friction wear surface, smooth and noiseless conveying. It takes minimum time to change the apparatus The bottle height gauge is adjustable for the quick and easy setting The height of the conveyor belt is adjustable to align with other machine of the line No container no cap arrangement The single A/C drive is synchronizing the platform turret and capping bowl, conveyor and star wheel. The conveyor, star wheel and platform turret is synchronized by the single motor. The S.S. matt finished body S.S. cladding or hard chrome plating of all exposed parts. The UHMW-PE guide profile for low friction wears surface. It is self lubricating leads smooth and noiseless conveying. Depending on the gauges and size of caps, the sealing pressure can varied Noise level and power consumption are very low SPECIAL FEATURES : The washing system of automatic chain for the conveyor belt There is afloat tank( holding tank) with or without stirrer In-built pre-inspection Nitrogen flushing Acrylic cabinet The cover of the conveyor is of acrylic UTILITY REQUIREMENT : Electrical Supply : Three Phase + Neutral + EarthingElectrical Load : 2 KWAir Pressure : 6 bar pressure 0.5 CFM

vial liquid filling machines

Get Price Quote

We are offering veerkrupa engineering are manufacturers and exporters of vial liquid filling machine , liquid filling machine manufacturers, vial liquid filling machine manufacturers, automatic liquid filling machines manufacturer, semi automatic liquid filling machine in ahmedabad , gujarat , india.

Injectable Volumetric Liquid Vial Filling And Rubber Stoppering Machine

Get Price Quote

Automatic Liquid Vial Filling

Get Price Quote

Vial Liquid Filling Machine (NKLFRS-120)

Get Price Quote

Salient Features Total cGMP modelContect Parts are of S.S. 316LM.S. Frame structure duly power coated and covered with S.S. sheetMachine can handle vial range from 2ml to 100ml and Rubber Stopper of 13mm, 20mm & 32mm (With the help of Change Parts)“NO VIAL NO FILL” System eliminates wastage of costly Liquid“No Rubber Stopper in Chute machine Stop System”Pre and Post gasing unit.Acrylic Cabinet with Aluminium Structure to maintain the humidity on Machine.Pick & Place type Rubber Stoppering Systme instead of standard Roller SystemAll Assemblies under top plate are positioned as for easy cleaning or maintenance Double dosing for 100ML is also possible. (With the help of Change Parts)All driving is through High quality imported Gear motor for better machine performance without vibration or leakage of oil of area floor from gear box.Machine speed can be adjusted through A.C. Frequency drive, which is time saving and the machine speed can be easily synchronized with unscrambler, scrambler and conveyor.Machine is provided with delrin conveyor belt to avoid sticking of vial on conveyor.Special clutch devices are provided on Star wheel for safety purpose.Vibrator bowl for rubber stoppering unit support to run machine with total claimed speed of machine.Vial Tray Collection unit for half stoppered vials.

Automatic Injectable liquid Vial Filling Machine

600,000 Per UNIT

1 Piece (MOQ)

injectable liquidwhen it comes to choosing a prominent and leading liquid filling machine manufacturer in ahmedabad, the jdm pharmatech is a trustworthy name. our products have been designed and engineered using state of the technology and materials that ensure .

Vial Filling Machine

Get Price Quote

The Automatic Twin Head Volumetric Liquid VialBottle Filling with Rubber Stoppering Machine Model LIQFILL-40IR is suitable for Round Vials and Bottles with maximum speed of 40 Products per minute. The Machine can give Maximum speed of 40 Vials Bottles per minute depending on nature of Liquids, VialBottle Neck Diameter, Fill Volume and Rubber Stopper size. Machine construction in fully Stainless Steel finish including machine frame structure. Machine with built-in Turn Tables at In-feed with individual drives to match the speed of Filling and Stoppering for smoother operation. All parts coming in contact with Liquids and Rubber Stoppers are made from SS 316 and Teflon. Machine suitable for full as well as half stoppering.

Vial Filling Machine

Get Price Quote

Automatic Volumetric Liquid Vial Filling & Stoppering (Full & Half bunging) Machine. The Basic Unit Consists Of One Or both side Turn Tables, S.S. Slat Conveyor Belt, Unique Co- eccentric Simultaneous Gassing with Filling. The Machine Is And Can Be Run Totally Through Touch Screen HMI, PLC Control And The Machine Is Based On Servo Motor Drive, Being The Stoppering Of Rubber Bungs Is Carried Out With The Help Of Vacuum Air Pressure. The Main Characteristics of the Machine Is That The Volume Can Be set On the Touch Screen HMI within a two second. The Machine Has an Output Speed of 200 Vials per Minute but Depending upon the Fill Volume and Container Dia. size Or the Quality & Viscosity of Liquid.

Vial Filling Machine

Get Price Quote

Laxmi Pharma Equipment offers complete integrated Pharmaceuticals packaging solution for small volume parental and large volume parental our comprehensive Vial line synchronized from filling to labeling machine along with class 100 Laminar air flow system under one roof and in house Manufacturing. Complete line (Vial Filling Machine) carefully design and developed as per New Pharmaceuticals Guide line and GMp Norms along with Modest Electronic Device programming and automation with timely service support.

Automatic Vial Powder Filling Machine

Get Price Quote

For ensuring quality products at buyer's end, we check each and every product at diverse stages including production, packaging and delivery. Obtain the extensive array of products from our well-established inventory located in Ahmedabad(India). Salient Features : Compact cGMP model Machine provide production output up to 240 vials/minute “No Vial, No Filling” system eliminates wastage of costly powder Multiple Dosing System High Volumetric Filling Accuracy of ± 1% of uniform density Injectable powder can be ensured by setting the depth of piston in the port of powder wheel Built-in Rubber Stoppering Unit saves lot of space in the Sterile Area & reduces the length of Laminar Flow Individual drive for the filling & sealing to match the speed of filling & sealing All motors are provided with appropriate contractors and relays for the protection against any overload or jamming Safety clutch system to avoid Vial breakage Variable Frequency Drive for speed control All contact parts are easily removable for mandatory Autoclaving/ Sterilization Digital counter for counting production output

Vial Filling Machine

Get Price Quote

Our range of vial filling machines are operates on the volumetric theory of liquid. It is made from high grade stainless steel. It contains matt finish body. To provide precise filling operation with complete elimination of seepage and spillage, we have designed perfectly suitablevial filling machine with economic range. Our vial filling machine is made as per GMP standard. Vial filling machine can be set for varied filling range from 5 gms to 1000 gms for single stroke. It provides output of 20 to 40 fills per minute. Output and accuracy of the machine depends upon several criteria. Bulk concentration Filling volume Consistency of material Uniformity of material Means of power supply of machine are 0.5 HP, 3 phase, 50 Hz and 440 volts. It is available with overall dimension 550 mm (L) x 700 mm(W) x 1730 mm (H). No special skill require to operate Safe handling operations Quick and efficient Highly precise operation On-line weighing system

cGMP Vial Powder Filling Machine

Get Price Quote

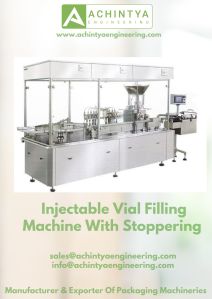

Injectable Vial Filling Machine With Stoppering

Get Price Quote

Injectable Vial Filling Machine With Stoppering, packaging machineries

Vial Filling Machine

Get Price Quote

Vial Filling Machine, Ampoule Washing Machine, Pharmaceutical Consultants