Multi Jet Vial Washing Machine

400,000 Per piece

1 piece (MOQ)

rotary vial washing machine

Get Price Quote

1 Unit (MOQ)

Automatic High-Speed Rotary Vial Washing Machine The Vial Washing Machine washes vials with minimal contact between machine parts and the vial. Our vial washing equipment effectively washes various sizes of vials with the assistance of changing parts. Vial Washing Machine | Internal & External Vial Washer The Vial Washing Machine washes vials with minimal contact between machine parts and the vial. Our vial washing equipment effectively washes various sizes of vials with the assistance of changing parts. Automatic Rotary Vial Washing System: A Manufacturer and Exporter in India Harikrushna Machines Pvt. Ltd. is an ISO 9001:2015 and CE-certified pharmaceutical packaging machinery manufacturer and exporter in India. The pharmaceutical, veterinary, and biotech industries widely use our system. The specially designed Gripper System holds the vial from the neck and inverts it until the washing operation. Again After washing, the machine releases the vial on the out-feed feed screw system in a vertical position, ensuring positive wash vials. Vial washing machines play a critical role in the pharmaceutical industry for the following reasons: Ensuring Product Quality and Safety: Vial Washing Machines remove particles and residues from vials used for pharmaceutical products. This process is crucial for maintaining the integrity, purity, and safety of the drugs. Clean vials reduce the risk of contamination and ensure that medications are safe for patient use. Compliance with Regulatory Standards: Pharmaceutical manufacturing is subject to stringent regulations and quality standards imposed by regulatory authorities. Our vial washing system meets Good Manufacturing Practices (GMP) needs and ensures compliance with cleanliness standards. Prevention of Cross-Contamination: Vial washing machines help prevent cross-contamination. Maintaining Product Efficacy: Vial Cleaning Machine clean vials are essential for maintaining the efficacy and stability of pharmaceutical products. Contaminants or residues left in vials can interact with drug formulations, affecting their shelf life. Cost-Efficiency and Productivity: Manual vial washing is time-consuming, while automated external vial washing machines offer significant cost savings and increased productivity. Enhanced Reputation and Customer Trust: Pharmaceutical companies that invest in high-quality vial washing technology demonstrate their commitment to product quality, safety, and patient well-being. The suitability of a specific type of vial washer for an application relies on factors such as the size and shape of the vials, the desired cleaning level, and the production speed. We also provide customized vial washing systems tailored to customer requirements with reasonable cost.

Best Deals from Vial Washing Machine

Auto. Linear Vial Washing Machine

Get Price Quote

Automatic linear vial washing machine, model: hvw-80/150&250 gmp suitable for washing of vials (2ml to 30ml) (dia. 14mm to 35mm) all contact parts made out from ss 316 entire frame covers & non contact parts made out from ss 304 needles enter in to the container during washing cycle to meet cgmp requirement low water consumption quick change over of parts for other size of containers complete flexibility with user for washing cycle machine provides 4 water washes, 3 air washes and 1 silicon (optional) operation containers feed from the decartoning station (optional) are received on a unscrambler through visual inspection unit (optional). An infeed worm inverts container as neck down position and feeds them through specially design indexing device. The devicecarry the container forward and stops. nozzles carrier enters into the container and activates the jet of water/air. the air/water flow is deactivated after the washing cycle is over. device get indexing for next wash. a separate pumping station (optional) gives the right quantum of water at the desired pressure. in the absence of separate pumping station we can provide the recirculation & siliconising system on request. washed container are again inverted to neck upward position to collect in trays/directly feed to tunnel.

Multi Jet Ampoule Vial Washing Machine

125,000 - 450,000 Per Piece

1 Piece (MOQ)

Automatic Linear Tunnel type Vial Washing Machine

Get Price Quote

Automatic External Vial Washing Machine

Get Price Quote

We are a name to reckon with, when it comes to manufacture Automatic vial washing machines. These machines are flawlessly designed in sync with set industrial norms and standards. These are provided with high grade components and compatible for washing the pharmaceutical vials automatically and promptly. Our proficiency lies in customizing these machines in accordance with clients' specific demands Technical specifications Total cGMP ModelTotal machine Structure is made of S.S. PipeAll Water contract part will be Delrin / food grade materialBottom washing & Drying ensures Vials is cleanedChangeover time will be less then 10minNo Change parts required from 2ml to 100ml VialsMachine can be used for both Powder and Liquid Inject able LineSpecial Design Food grade Conveyor ensures water transfer from conveyor to drain tank, which does not allow water to transfer on drying station�No Vial � No Air/Water� Machine stop systemMachine Stop system�No Water� Machine Stop SystemCabinet door open machine stop systemPLC with touch screen HMISpecial micro Nozzles for bottom drying Properties Tensile strengthDurableSturdy designsLong lastingFlawless performanceCorrosion resistant

Vial Washing Machine

Get Price Quote

The External Vial Washing Machine is designed to wash the outer surface of round shaped Vials [5ml to 100ml Vials]. This machine washes the outer sides of Vials and eliminates the particles that are formed on the vials, which are previously filled and sealed.

Automatic Linear Vial Washing Machine

Get Price Quote

Vials are pushed from Infeed tray and then move on Wiremesh conveyor Belt, which align the Vial in correct position, to enter into the carrier pocket with help of oscillating guide rails. Oscillating arm deliver the vial inside pocket in mouth down position over spraying nozzles. Multijet sprayers Set at the top cause the total External and Internal surface to be Washed. The Sprayers nozzles are movable in fixed Up-Down position as per Customer Requirement. To avoid any possible cross contamination between two different waters. Each washing station is provided with an independent Circuit. Carrier pocket is moving with indexing motion. When the baskets have completed their motion the needles are lifted. They penetrate the Bottles, Spraying Jets of water or compressed air then Return Down. The baskets movement then advances by one Station. Each station of Vials passes through the washing cycles selected.

Rotary Ampoule & Vial Washing Machine

Get Price Quote

Machine provides 4 water washes & 3 air washes complete flexibility with user for washing cycle. all contact parts made out from ss316 entire frame covers & non contact parts made out from ss 304 nozzles enter into the container during washing cycle to meet comp requirement low water consumption quick change over with minimum use of tools. all contact parts with d.m. Water and distilled water of s.s. 316 construction and argon arc welded. the unit built on s.s. Square pipe frame and totally encompassed with s.s. Coverings the washing section is totally covered with acrylic cabinet. all exposed parts are of s.s. 304 or hard chrome plated or brass for corrosion free long life. fixed top nozzles at each washing station ensures external washing of bottles at the same time of internal washing. the flow of washing medias stop during the indexing of chain, saving straight 25% on utilities. the system of solenoid valves and optional tanks, pumps and filters is engineered for long trouble free life & tool proof operation.

Ampoule Vial Washing Machine

Get Price Quote

Ampoule Vial Washing Machine is used for the filling & sealing of glass ampoules. Our Machines is extensively uses in pharmaceutical, cosmetic & chemical industry. We manufacture Vial Washing Machine as per our standard model as well as custom made equipments. Our Vial Washing Machine is manufactured using high grade stainless steel, known for its silent operation and minor maintenance. Furthermore, we supply customization as per the specific necessity of the clients in order to meet their needs. We are also counted as the most excellent Exporter of Ampoule & Vial Multi Jet Washing Machine in Ahmedabad. We have earned the tag of most reliable Automatic Vial Washing Machine Manufacturer and Supplier in India. Machine with specially designed Gripper system holds the ampoule from Neck and invert the ampoule till the washing operation completed and again after washing let loose the ampoule on out feed worm system in vertical position ensures positive wash of ampoules. Our Ampoule Vial Washing Machines is suitable to wash 1ml to 20 ml Ampoules & 2ml to 250ml with the help of change parts, Ampoule feeds through Feed worm to infeed Star Wheel and specially designed Gripper hold the Ampoule from neck and invert the ampoule and move it further on rotary moving system for washing process.

Automatic Linear Vial Washing Machine

Get Price Quote

The Automatic Linear Tunnel type Vial Washing Machines Model VIALWASH-240 is suitable for Round Vials sizes of appx. 5 ml to 30 ml pack size with maximum speed of 240 Vials per minute, Specially designed machine also available for 2 ml Vial Size. Machine construction is in Stainless Steel finish including frame structure. All parts coming in contact with Washing Zone and Jets are made from SS-316 Materials. Intermittent handling of Vials ensures the maximum time for washing and also saves the Water through No Container - No Water system. Machine also offers various customized options for washing sequence as per customers requirements. Washing process takes place with Five different Washing Zones each with 10 nozzles for optimum washing. Machine also equipped with external washing of Bottles.

Linear Vial Washing Machine

Get Price Quote

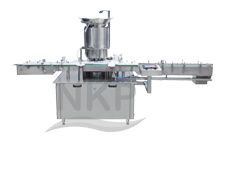

N.K Industries is pioneer in manufacturing range of Tunnel type Linear Vial Washing Machine. Various models are available to cater the requirement of Low production to Moderate and higher production as per the modern inject able plant requirement.

AUTOMATIC ROTARY VIAL WASHING MACHINE

Get Price Quote

WASHING SYSTEM Machine provides 3 water washes & 3 air washes Complete flexibility with user for washing cycle Suitable for washing of Vials (2ml to 100ml) (dia. 14mm to 52mm) All Contact parts made out from SS 316 Entire covers & non contact parts made out from SS 304 Needles enter in to the container during washing cycle to meet cGMP requirement Low water consumption Quick change over of parts for other size of containers The Grippers provided ensure efficient holding of different sizes of vials.

Automatic External Vial Washing & Drying Machine

Get Price Quote

We are offering automatic external vial washing & drying machine. Model no. nkew - 100 nkew - 200 direction left to right left to right production rate up to 100 vialsmin. (for 5 ml vial) up to 200 vialsmin. (for 5 ml vial) electrical supply 5.0 hp 5.0 hp power requirement 415 volts, 3 phase (4 wire system), 50 hz 415 volts, 3 phase (4 wire system), 50 hz height of conveyor 900 mm (approx) 900 mm (approx.) dimensions 3400 mm (l) x 915 mm (w) x 1400 mm (h) 3470 mm (l) x 980 mm (w) x 1400 mm (h)

Automatic Linear Vial Washing Machine

Get Price Quote

Machine manufactured as per cGMP standards. Machine fitted with one set of change parts suitable for 5ml to 30ml vials. Various models available from 60 VPM to 400 VPM. (Please have a look at technical specification column) Machine is suitable for 2ml to 100ml Vial Sizes with the help of minimal change parts. Water recycling arrangement is possible as per requirement. Basic Frame of the Machine totally fabricated from SS-304 materials. All parts coming in contact with washing zone are made from SS 316L materials Machine equipped with safety devices to ensure smooth and silent operation with HIGH rated output. Machine totally rigid and withstands continuous operation for long working hours without any trouble. Washing chamber having various spray zones. Spray duration is electrically controlled by magnetic valve. HIGH pressure spray nozzles entire into the vials during washing time to insure perfect wash of vials. The machine will be provided with SS-316L pumps and SS-316L tanks All contactor and relay from Telemechanic. Main Drive: Gear Motor Make-MGM Varvel Conveyor Drive: Gear Motor Make-MGM Varvel Solenoid Valve from ROTEX Make. Conveyor Belt made from SS 304 Material. Wirewooven Type. All pipe fittings made from SS 316L Materials. The emergency stop button is provided with both ends (In feed & Out feed Side).

Automatic Linear Vial Washing Machine

300,000 Per UNIT

1 piece (MOQ)

Automatic Linear Vial Washing Machine – JDM Pharmatech is a renowned name in the world of manufacturing Avant-Garde medical products Pharmaceutical Packaging Machines. Our automatic linear vial washing machine has been engineered to perform with efficacy and ensure thorough cleaning of the surfaces of the vial. This is a completely automatic machine that ensures cleansing of the surfaces of the vial without manual intervention

High Speed Rotary Vial Washing Machine

Get Price Quote

Automatic Linear Vial Washing Machine

Get Price Quote

Automatic Linear Vial Washing Machine, Ointment Process Plant

Automatic External Filled Vial Washing Machine

Get Price Quote

We are offering automatic external filled vial washing machine. Complete cgmp construction & design can handle vial sizes from 5 ml (ø 25mm) to 100 ml (ø 54mm) with only change part of vial separators for proper positive feeding with required intervals 'no vial no washing' & 'no vial no air' system eliminates wastage of water & air. Machine is equipped with plc system. Has polycarbonate guards on machine. Machine stops if water in storage tanks's level goes below minimum & there is no inflow triggering alarms. Machine stops if the compressed air pressure drops below the set pressure and triggers alarms. Machine stops if any toppled vial inserts the track of the machine

Vial Washing Machine

Get Price Quote

We are providing vial change Parts for all make Cap sealing Machine.We are providing Vial Holding Pockets for all Size of Vials and Bottles.