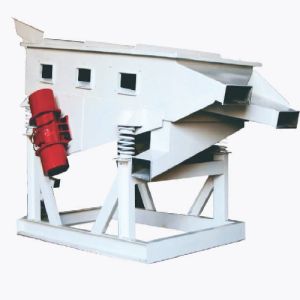

Vibrating Screening Machine

50,000 Per piece

1 piece (MOQ)

Vibrating Screen Machine

50,000 - 100,000 Per Piece

1 Piece (MOQ)

We are one of the leading Manufacturers, Suppliers, Distributors of this highly commendable range of Vibrating Screen Vibrating Screen has come out with a most advance design of screens for grading of fine, wet and difficult to screen materials. The screens works on the principle of gyratory motion. The unique features of this type of sieve is its high capacity using minimum space and less power. The screen has specially designed multi-directional vibration system which prevents blinding of sieves. The material to be screened is fed from the top and collected simultaneously from outlets of different decks. These screens can handle wide range of materials such as heavy, light, dry, wet, coarse or fine. The company manufactures various sizes to suit individual requirement in M S and S S construction.. Vibratory motion is the most effective method for screening. It causes 100% rotary motion and causes dispersion stirring & stratification of material to be sifted. Feed material constantly flows in Horizontal motion along a loop pattern on Vibro screen surface."EXCEL" Vibro screen provides optimum screening & assures maximum feed-rate & efficiency The vibrating screen is an important part of the incepting steps in any industry. The companies which require the processes or have the steps involved in the separation, sizing, and sorting the various materials and their parts out have the operations done with the good quality screens. Using the screens These screens are also called the vibrating sieves. The sieves we use regularly at home is in the ground level separation .i.e. small scale while the vibrating screen is the one which is used as a part of the initial processing of the raw materials in any industries. The cement industries, powder industries, companies that make spices, which produce fillers for food products etc. should have the correct mesh size to follow for the particles which are separated by these screens. Shape size make etc. These are availed in huge flat, basket shaped, cylindrical, and curved or even the irregular format of shape. The size would however vary from the products used to separate. The basic principle behind such separation is the size of the mesh and the gravitational force. The dimensions decide the shape and kind of products to be separated.These screens are highly durable and tough made from the metals that are hard enough for the usage and corrosion free too. To avoid spillages as well there are mechanisms provided in the screen feeders.

Best Deals from Vibrating Machine

vibrating sieve machine

70,000 Per Piece

1 Piece (MOQ)

Salient Features : Stainless steel GMP construction with SS304 or 316 contact parts. Faster output at low power consumption. Double deck arrangement can be provided. Fitted with Vibro Motor. Provided lid for dust free operation. Easy to dismantle to clean screens. Provided sieve with silicone sealing. Available in 12, 20, 30, 36 and 48 inches size model.

Auto Separation Vibratory Finishing Machine

80,000 - 100,000 Per piece

1 Piece (MOQ)

Auto separation Vibratory Finishing Machine are designed with in built media & parts separation with flapper, the unload plate can float on the media at work, and while the separating work part from media, the unload dam flapper sink, parts can be separated easily with simple operation.Advantages Deburring Polishing Fine Finishing Surface Smoothness Mirror Polishing Descaling Edge Rediusing Derusting Features & benefits 85-100 % separation can be achieved Automatic separation of part & media Can be added in continues production system Rugged one piece welding structure Bowl with 80 ± 3 Shore PU lining Powered by heavy duty vibratory motors Model : “NAKU” vibro Finishing Machine available in Rubber & PU Lining. Machine motors are manufacture by us. Motor power supply is 3 Ph. 440 V 50 Hz. Model Machine Capacity Machine Dia. (M.M.) Motor HP NVF 60 60 Lit. 880 1 NVF 90 90 Lit. 950 1 NVF 120 120 Lit. 1020 2 NVF 200 200 Lit. 1150 2 NVF 300 300 Lit. 1300 3 NVF 400 400 Lit. 1450 5 We are also providing Consumable items of vibro finishing machine like Ceramic Media, Plastic Media, Steel Media, Finishing Compound, Vibratory Motor, Corn Cobb. Additional Information: Delivery Time: 4 to 5 Weeks

vibrating sieve machine

55,000 - 385,000 Per piece

1 Number (MOQ)

Vibratory Screen Separator Machine

1,400,000 Per Piece

1 Piece (MOQ)

Vibrating Polishing Machine

Get Price Quote

1 Piece (MOQ)

Electric Vibrator

Get Price Quote

We are offering electric vibrator. Prime mover :2 or 3 h.p. & 1 or 3 phase, 2800 rmp electric motor. Accessories :revolving base frame stand & needle fitting attachments suitable needles :25/30/40/60 mm needle with 6 mtr. Long flexible shaft.

High Vibration Fly Ash Brick Making Machine

1,540,000 Per Set

Vibro Machine

Get Price Quote

As Per The Variegated Requirements Of Our Clients, We Are Offering A Broad Collection Of Vibro Machine. The Offered Machine Is Precisely Engineered Using Basic Components And Advanced Techniques Under The Surveillance Of Trained Professionals As Per The Set Industry Norms. Our Offered Machine Is Widely Used For Mass Finishing Work Of Surface. Clients Can Avail This Machine From Us At Affordable Rate. Features: High Efficiency Sturdy Construction Unmatched Quality

Vibrating Concrete Road Paver Machine

450,000 Per Piece

1 Piece (MOQ)

Round Vibrating Sifter Machine

120,000 Per Piece

1 Piece (MOQ)

automatic vibratory screen separator machine

50,000 - 100,000 Per piece

1 piece (MOQ)

Vibratory Rammer Machine

Get Price Quote

Vibratory Rammer Machine is designed and developed is accordance with international industrial standard and widely used in various construction fields. These are compact in size and acclaimed for excellent functioning and energy efficiency. User friendly Vibratory Rammer Machine is acknowledged for its reliability, durability, easy maintenance and longer functional life. These are properly quality checked on various parameters to ensure its excellent quality. Besides, these are very easy to install and operate and also ensure less maintenance cost. Key Features: It has strong impact force though it is small and light. Multipurpose use with manoeuvrability, they are used for confined area, trench work, backfill and repairing work on asphalt. Suitable especially for compacting the roadbed with low water content that heavy vibratory compactor could not work.

Vibration Testing Machine

Get Price Quote

The Vibration Testing Machine, provided by us, is reckoned due to its quality & make. Only qualitative raw material can result top-notch product range. Thus, we procure it from dependable names in the industry and that too after complete quality confirmation. We make it much easier for you and thus, we have electronic payment system that will make transactions with complete security. Rest assured us for all the payment issues.

Vibrator Sand Screening Machine

Get Price Quote

The vibrating deck is powered by vibratory motor. The machine is available in various sizes. The amplitude and angle of throw can be changed to serve various applications. Wire mesh tightening feature is provided within the machine.

Vibro Trough Tub Vibrator Machine

Get Price Quote

Vibratory Trough Finishing Machine are ideal for processing larger and particularly longer items which cannot be process in a Vibratory bowl Type Finishing machine. Trough Vibrators has a U shape processing bowl which has been lined with polyurethane lining. Trough Vibrator Machine comes with heavy duty vibratory motor which is mounted under the tub, the motor has been designed for a continues and evenly distributed vibration motion throughout the trough Machine. For special application where part to part impingement is to be totally avoided, we can provide compartments in rectangular tub.

Vibrating Knockout Machine

750,000 Per Units

Vibrating Screening Machine

Get Price Quote

a) Single/Double Deck Vibrating Screens: Single and double-deck vibrating screening machines are designed for screening various materials in powder form. These machines are simple and robust in construction. Screen sizes are available of 1500 x 600mm, 1800mm x 800mm, and 2500mm x 800mm. Special sizes as per client requirements are also made available. The vibrating screens are also available with a magnetic system to remove fine iron and contamination from products like chemicals, pharmaceuticals and food products, etc. b) Multi-Deck Vibrating Screens: These are used for much superior, faster, and more accurate sizing, splitting, or correcting. The vibrating screening machine is designed for the sizing of minerals, ceramics, refractories, and other powders. The principle on which our multi-form grader operates is equally adaptable for the handling of many ceramic products as well! The unit is more than “Just a screen”; it is a precision tool for producing accurate grades, not merely a rough grouping of sizes. It is economical in regards to power and space; screen life is long; and low maintenance. It is adaptable to a wide variety of materials and conditions. Multi-deck vibrating screens are available in different models. Model Dimension HP JVS-01 5′ X 24 “ 1 HP JVS-02 6′ X 32 “ 1 HP JVS-03 8′ X 32 “ 1 HP Salient Features: · Long service life and extremely quiet because of maintenance-free vibrating elements.· The electricity consumed to screen every ton of material is low.· The circular vibrating screen has a simple structure so dismantling and changing the screen surface is very convenient. Our Vibrating Screen Machine is used for: · Chemicals· Pharmaceuticals· Aluminium Fluoride· Spices· Flour· Semolina· Turmeric Powder· Chili Powder· Mineral Garnet· Zircon· Medicines· Bulk Drug· Plastic· Rotomoulding Machine· Refractories· Wood Chips· Ceramic Pulp· Paper Mill· Packaging Line

Vibrating Screen Machine

60,000 Per Piece