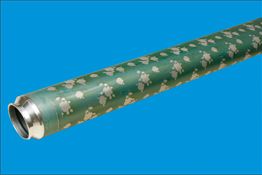

Rotary Screen

90,000 Per Piece

1 Piece (MOQ)

Vibrating Screen

Get Price Quote

Our company is quite known for the vibratory screens it supplies. We specialize in wholesale vibratory screen and offer profitable deals in it. We are also one of the in demand vibratory screen manufacturers in India.

Best Deals from Vibrating Screen

Vibratory Screen Separator Machine

1,400,000 Per Piece

1 Piece (MOQ)

Vibrating Screen

103,000 Per Piece

eccentric vibrating screen

Get Price Quote

We are offering eccentric vibrating screen

Rotary Screen

Get Price Quote

Techno Power engineering is best rotary Screen manufacturers, exporters and suppliers in ahmedabad. The rotary Screen desing and Manufacturing in cylindrical Shape. We offered multiple Cages for Separation of Material as per Client Requirement. The machine has a heavy-duty sharft wich made from EN-8 material fitted with Heavy-Duty bearing at both and. The Screen are making from spring steel materials with MS or S.S grade, as suitable with client Application. The machine desing with top covered and bottom discharge chute for prevent low dusting. The Rotary Screen in Widely Used in Minerals Industries, Agro- Product Industries, Stone Industries, etc.

nickel rotary screen

Get Price Quote

We will accomplish this goal by : Developing long-term relationships with our customers. Providing super quality product at competitive prices. Exceeding industry standards with exceptional customer and technical service. Maintaining our competitive position through leading edge technology. Quality Of Delta Screen / Penta Screen Get Positive Comment From Customers Worldwide, Featured With : Uniform open area, better paste, penetration High ductility, higher printing speed Sharp result with high viscosity Lower squeegee pressure Enhance the adhesion of photo emulsion Cost-saving & reliable

Vibro Screen

65,000 Per Piece

1 Piece(s) (MOQ)

Vibro sifters, also known as safety screeners, vibrating shifters, vibro sieves, check screeners or control sieves, are used to ensure the correct product quality of powders or liquids is achieved by removing oversize contamination. The Russell Compact Sieve® range of sifters is incredibly versatile and can be used for size based separation of almost any material. These vibrating sifters fit neatly into production lines, providing considerable screening capacity without requiring excessive headroom. Its innovative design means these machines are less than half the height of a traditional circular vibro sifter machine. Operating and cleaning is quick and easy, making this range of sifting machines perfect for all processing industries. A wide range of sizes and options means the machine can be tailored to suit your exact needs.

Vibrating Screen

Get Price Quote

SZF Series linear vibration screen is low consuming, high output, simple sturcture, easy maintain, no powder dispersed, automobile discharged. It is very useful in building industries, fertilizer, perlite and so on. We can be supplied of different sizes depending upon your required. These screening machines can be used universally for test screening or to produce between 2 and 4 screen fractions. A good screening effect is achieved by the circular vibration in the vertical plane. Vibration screens are very useful in plastics, rubber, ceramic, food, pharmaceutical, chemical, fertilizer, glass industries. Vibratory screens can be provided with dust proof cover as required. Vibrating screen can be supplied of different sizes depending upon capacity required. They can also handle slightly wet material.

Vibrating Screen

Get Price Quote

Features: Used for grading material by size. Can also be used for washing material, dewatering, descaling or any combination of these operations. Suitable to screen wide range of products such as Sand and Gravel, building materials, Minerals, Ores, Pellets, Sinter, Coal, Coke, Pet Coke, Lignite, Limestone, Dolomite, Chemical Products, Fertilizers, etc.

Vibrating Screen

Get Price Quote

We design and construct the vibrating screen in rectangular shape. - The machine offered with multiple decks as per client requirement of material separation. - Main structure is made from ISMC or IISMA steel section, heavy duty MS plate use for main body. - We also provide the necessary stiffener for body strength. - Machine shaft make form En8material. The springs are making form spring steel material, which gives good result of vibration and longer life of machine. The screens are making form spring steel material with MS or SS grade, as suitable with client application. - The vibrating screen machine are widely useful in the quarry industries, stone industries, chemical industries, minerals industries, food & Agro – product industries, etc… Fab-Tech Manufactures:- " Rectangle Vibro Screen,Vibrating Screen,Screening Machinery,Separation machinery,Stone Screening Machine,Single Deck Vibrating Screen,Double Deck Vibrating Screen,Multi Deck Vibrating Screen,Multi Stage Vibrating Screen,Reciprocating Screen "

Vibro Screen Machine

Get Price Quote

Vibro Screens, available in size from 24”to 60”” in diameter with convenient design; maximize screen surface, provide good rate of screening, one to multilevel screens giving desired numbers of predefined portions with absolute separations in various mesh sizes. The equipment also can be supplied with dust cover and other special accessories. Material of construction will be as per requirement of customer.Majorly used in:Guar Gum, Starch, Cellulose Food, Pharmaceuticals, Chemical, Minerals, etc…

Vibration screen machine

Get Price Quote

Vibro Screens are designed to perform effective size based separation in coarse as well as fine sizes. Vibro Screens use wire mesh or perforated or slotted sheets for carrying out separation of material on basis of size. Vibro Screens are designed on the principle of gyrator motion and are one of the most versatile and universally adaptable machines working across spectrum of industries. Vibro Screens can carry out various duties including screening of any powder or granules, sifting and grading or classification, removal of oversize/ foreign material before packing your finished product, lump/ under-size chips/ dust removal from powder/ granules, solid liquid separation/ filtration/ grit removal from Slurry, Syrup or Oils, Fiber/ Husk Recovery from liquid stream. Vibro Screens are used by Industries like Agro, Agro Processing, Ceramic, Chemical, China Clay, Dehydrated Food, Dyes and Pigments, Ferro Alloys, Foundry, Engineering, Food, Mines and Mineral, Metal Powder Processing, Plastic, PVC, Petrochemical, Paper, Rot molding and many more.Vibro Screens are very versatile process equipment and provide reliable and economical solutions for spectrum of size based separation operations performed in most of the industry sector / applications due to its flexibility and distinctive advantages. Vibro Screens are your best bet for performing the operation of Classification, Grading, Oversize/undersize Removal, De-dusting, De-watering, De-lumping, Fiber Recovery, Fiber Separation, Continuous Filtration or any type of SIZE based separation

Vibratory Screen

Get Price Quote

AEGIS have had years of field and development experience and are experts at solving screening problems. Vibratory screens are manufactured with single or multiple deck and are used primarily for grading of material by size. The working principle of Vibratory Screen is simple. The vibration effect leads to the screening of material through the screen (mesh) of appropriate size. The vibration effect is caused by the rotation of shaft with its eccentric weights. The throw of the vibrating screen can be easily varied by adjusting the eccentric weights. Application Used for grading material by size Can also be used for washing material, dewatering, descaling or any combination of these operations Suitable to screen wide range of products such as Sand and Gravel, building materials, Minerals, Ores, Pellets, Sinter, Coal, Coke, Pet Coke, Lignite, Limestone, Dolomite, Chemical Products, Fertilizers, etc. advantages Low equipment cost and also low running costs Simple design with stable operation Easy to install, operate and maintain Strong vibration achievable leading to high screening efficiency Very low vibrating noise Dusty, corrosive or toxic materials can be completely confined by the enclosure, offering dust free and safe working environment

nickel rotary screen

Get Price Quote

Our Rotary Nickel Screen mesh ranges from 25mesh to 165mesh, and length from 1000mm to 3800mm. We provide repeat 640mm, 820mm, 914mm, 1018mm which are of, high quality and can replace the similar products as well from Europe. All other specifications could be customized. Our company pays great attention to product quality, our quality control department inspects every piece of Rotary Screen for the surface appearance, thickness, circumference, open area, and makes sure of no exceeded block holes. It all began ad our dream – to redefine the standards in INDIA for printing screen industry. With all the knowledge and the experience as a guiding beacon, we have moved ahead with steady strides and constant zeal to become one the renowned company in INDIA. Our fully modern equipments along with very hardworking, capable and qualified team, has enabled us to achieve high standards and prestige in the Rotary Printing Screen industry. The well-deserved success of ROOPA SCREEN PVT. LTD. Lies in the philosophy of quality as it is the utmost both for customer and us. The commitment and dedication to achieve this philosophy has resulted in satisfying all our customers. For the past years, we have served hundreds of customers worldwide. Finally, we want to convey that our motto of satisfaction to both the customers and the employees has made us reach the place where we are today. Thanking and looking forward to hear from you soon and assuring our best services at all the times. ROOPA SCREEN PVT. LTD. Is committed to operate a successful business by developing. Manufacturing marketing and supporting quality Rotary Printing Screens for the world textile printing industry. We will accomplish this goal by: Developing long-term relationships with our customers. Providing super quality product at competitive prices. Exceeding industry standards with exceptional customer and technical service. Maintaining our competitive position through leading edge technology. Uniform open area, better paste, penetration High ductility, higher printing speed Sharp result with high viscosity Lower squeegee pressure Enhance the adhesion of photo emulsion Cost-saving & reliable Standard Screens are the reliable choice for the basic designs, features with big holes and strong dams, which is favorable for the penetration of dyestuff. Standard Screens are normally used for coarse substrates, blotches, deeper penetration, gold and bronze prints.

Vibrating Screen

Get Price Quote

* Treatment of rejects from high consistency cleaner and other screening. * Remove rejects like plastic, knots etc. * Easy Maintenance. * Size as per requirements. * Made from M.S. fabricated body with S.S. 304 Screen. * Perforated Screen of 2.5 to 3.0 mm hole.

Vibratory Screen

Get Price Quote

Precious Vibrating screens are constructed from M.S prime plate with perforated woven screens, supported on 8 heavy springs at its 4 legs, drive through eccentric shaft. The discharge chutes are separate for each deck of screen and suitable feed hopper at one of the end

Vibro Screen Machine

80,000 Per Piece

10 Piece (MOQ)

Vibratory Screen

30,000 Per Piece

Vibrating Screen

125,000 Per Piece

Rotary Screen

Get Price Quote

We FR Engimech Private Limited provide our clients with Rotating Screens, which are specially developed for efficient and economical removing of striped solids. Higher flow capacities can be used due to continuous and self-cleaning effect of the Rotating Screens. Reckoned for low operational costs, these precisely engineered Rotating Screens are sturdy.

Vibrating Screen

Get Price Quote

Our highly efficient vibrating screening machines are widely preferred for the screening of bulk as well as outsized sized substances such as coal, minerals and coke. Our products are manufactured after comprehensive market study and the requirements of the customers. Hence they have excellent features since we eliminate the negative aspects of the machines available in the market. Furthermore, we offer these with diverse choices, which comprises of adjustable angling, spray bars fixed on decks to confirm superior working as well as performance. Our machines offer precise sizing with high output per square foot. They need minimal maintenance and are very cost-effective. Our machines can be installed effortless and are very compacted. These consume power-efficiently and are accessible at market leading prices. We are the chief Vibrating Screens Exporter, Vibrating Screens Supplier, Manufacturer of highly efficient Vibratory Screens in India.

Vibrating Screen

Get Price Quote

We are one of the well established supplying a wide range of Vibrating Screen

Vibrating Screen

Get Price Quote

Treatment of rejects from high consistency cleaner and other screening.Remove rejects like plastic, knots etc.Easy Maintenance.Size as per requirements.Made from M.S. fabricated body with S.S. 304 Screen.Perforated Screen of 2.5 to 3.0 mm hole.

Vibratory Screen

Get Price Quote

Many types.. For screening, scalping and washing.. For crushed stone, gravel, ore, coal and other materials, in which various lumps are to be separated into specified sizes.

Vibrating Screen

Get Price Quote

Our company has emerged as one of the leading Manufacturers of Vibrating Screen. We provide Circular Vibrating Screen and Single-Deck Vibrating Screen on the slinger conveyor to remove oversize aggregates received from the 4-bin feeder. We have our dedicated clientele for our Industrial Vibrating Screen.

Vibration screen machine

65,000 Per unit

1 Unit (MOQ)

rotary drum screens

Get Price Quote

Is the most advanced fine rotary drum screen now available in India. Screens are highly recommended as primary screening equipment in municipal sewage treatment plant and effluent treatment plants of various industries like Food processing, Rayon and textiles, Paper and pulp, Pharmaceuticals, Tanneries, Slaughter houses and so on. Is installed at an inclination of 35° with the horizontal in to the channel of treatment plant. The wastewater flows in to the open end of the wedge wire drum. While the filtered wastewater comes out from the sides of the drum passing though the wedge wire, the solids of the size more than the bar spacing are retained on the surface of the drum itself.

Motorized vibrating screen

Get Price Quote

Vibrating Screen

Get Price Quote

Backed by a team of highly experienced technician we are capable of providing premium grade Vibrating Screen to the Client. Our offered Screen is manufactured with the fine quality materials from the fine materials which exit in mixed form. These Vibrating screen are highly utilized for various stand-alone operation in scalping and screening and hence used in various application in steel plant, Fertilizer industries, cement plant, pharmaceutical industry, glass industry etc. Our in- house quality expert checks the entire range on Vibrating screen various quality parameter to ensure flawlessness. Each style comes in standards sizes but can be customized. Additionally we offer this vibrating screen system at most affordable rate. Features High screening capacity Excellent performance Simple structure Available in standard size Custom design is also available