Gyro Screen

45,000 - 375,000 Per Nos

1 Piece (MOQ)

Steel Vibro Sifter

110,000 Per Piece

1 Piece (MOQ)

Best Deals from Vibro Sifter

Gyro Screen

43,000 Per Piece

1 Piece (MOQ)

Vibro Sifter Machine

Get Price Quote

1 Piece (MOQ)

Vibro Sifter Machine

95,000 - 350,000 Per piece

1 Piece (MOQ)

Vibro Sifter Machine

Get Price Quote

1 Piece (MOQ)

Vibro Separator Machine

65,000 Per Piece

1 Piece (MOQ)

Gyro Screen

Get Price Quote

Circular Vibrating Screen has come out with a most advance design of screens for grading of fine, wet and difficult to screen materials. The screens works on the principle of gyratory motion. The unique features of this type of sieve is its high capacity using minimum space and less power.The screen has specially designed multi-directional vibration system which prevents blinding of sieves. The material to be screened is fed from the top and collected simultaneously from outlets of different decks. These screens can handle wide range of materials such as heavy, light, dry, wet, coarse or fine. The company manufactures various sizes to suit individual requirement in M S and S S construction. Vibratory motion is the most effective method for screening. It causes 100% rotary motion and causes dispersion stirring & stratification of material to be sifted. Feed material constantly flows in Horizontal motion along a loop pattern on Vibro screen surface."EXCEL" Vibro screen provides optimum screening & assures maximum feed-rate & efficiency The vibrating screen is an important part of the incepting steps in any industry. The companies which require the processes or have the steps involved in the separation, sizing, and sorting the various materials and their parts out have the operations done with the good quality screens. Using the screens These screens are also called the vibrating sieves. The sieves we use regularly at home is in the ground level separation .i.e. small scale while the vibrating screen is the one which is used as a part of the initial processing of the raw materials in any industries. The cement industries, powder industries, companies that make spices, which produce fillers for food products etc. should have the correct mesh size to follow for the particles which are separated by these screens. Shape size make etc. These are availed in huge flat, basket shaped, cylindrical, and curved or even the irregular format of shape. The size would however vary from the products used to separate. The basic principle behind such separation is the size of the mesh and the gravitational force. The dimensions decide the shape and kind of products to be separated.These screens are highly durable and tough made from the metals that are hard enough for the usage and corrosion free too. To avoid spillages as well there are mechanisms provided in the screen feeders.

Vibro Sifter Machine

50,000 Per piece

1 piece (MOQ)

An SS (stainless steel) vibro sifter, also known as a vibro screen or vibrating sifter, is a type of equipment used to separate, classify, and filter powders, granules, and other bulk materials. It utilizes vibration to help achieve accurate and efficient screening. Here’s a detailed look at its features and applications: How It Works: Design: The vibro sifter typically consists of a circular screen or mesh mounted on a frame, with a vibrating motor or vibrator attached to the screen assembly. Vibration Mechanism: The vibrating motor generates vibrations that are transmitted to the screen. These vibrations cause the material to move across the screen and separate based on size, density, or other properties.

VSM48 Vibro Sifter Machine

120,000 Per Piece

1 Piece (MOQ)

Confider Industries stands as a beacon of excellence in the realm of food processing machinery, offering an extensive array of products tailored for both domestic and commercial applications. With a diverse portfolio comprising over 90 meticulously crafted machines, our company epitomizes innovation, reliability, and superior quality. From humble beginnings, we have grown into a globally recognized brand, catering to the needs of customers worldwide. At the heart of our success lies a relentless commitment to delivering top-notch products that exceed expectations. Every machine manufactured by Confider Industries undergoes rigorous quality control measures, ensuring precision engineering and durability. Whether it's a small-scale operation in a home kitchen or a large-scale industrial setting, our machines are designed to meet the diverse demands of modern food processing. One of the hallmarks of Confider Industries is our unwavering dedication to customer satisfaction. We understand that purchasing a food processing machine is an investment, and thus, we go above and beyond to provide unparalleled after-sales support. Our team of experts is readily available to assist customers through calls and video calls, offering guidance, troubleshooting, and technical assistance whenever needed. We believe in building long-lasting relationships with our customers, and our commitment to after-sales service reflects this ethos. Furthermore, Confider Industries takes pride in its global reach. With an extensive network of distributors and partners, our machines are delivered to customers across continents. Whether it's a bustling city in Asia, a remote village in Africa, or a thriving metropolis in Europe, our products have found their way into kitchens and food processing facilities worldwide. This global presence underscores our reputation as a trusted provider of food processing solutions on a global scale. Innovation is at the core of everything we do at Confider Industries. We continuously invest in research and development to stay ahead of market trends and technological advancements. Our team of engineers and designers work tirelessly to develop cutting-edge solutions that streamline processes, enhance efficiency, and elevate the overall user experience. From state-of-the-art automation technologies to eco-friendly designs, we strive to push the boundaries of innovation in the food processing industry. Sustainability is also a key focus for Confider Industries. We recognize our responsibility to minimize our environmental footprint and embrace sustainable practices throughout our operations. From sourcing materials responsibly to optimizing energy efficiency in our manufacturing processes, we are committed to fostering a more sustainable future for generations to come. In conclusion, Confider Industries stands as a beacon of excellence in the food processing industry, offering a diverse range of high-quality machines for domestic and commercial use. With over 90 machines in our portfolio, a global presence, and a steadfast commitment to customer satisfaction, we continue to set the standard for innovation, reliability, and excellence in food processing.

Stainless Steel Vibro Sifter

75,000 Per Piece

1 Piece (MOQ)

Salient Features : Stainless steel GMP construction with S.S.304 or 316 contact parts. Faster output at low power consumption. Double deck arrangement can be provided. Fitted with Vibro Motor. Provided lid for dust free operation. Easy to dismantle to clean screens.. Provided sieve with silicon sealing. Available in 20" Dia, 30" Dia, 36" Dia., 48" Dia size sieve model. Flame - proof electrical motor can be provided as option

18INCH SS VIBRO SIFTER

30,000 - 50,000 Per piece

1 piece (MOQ)

Pharma Vibro Sifter

111,000 Per Piece

We are dedicatedly engaged in manufacturing and supplying a commendable range of Pharma Vibro Sifter. Operation: Vibration is generated in three different planes along the vertical axis by means of a specially designed vibratory motor having off centered weights at the top and bottom end of the motor shaft The angle of lead of the lower weight to the upper weight provides variable screening pattern & output Product Details: Available in standard and GMP models with contact parts fabricated from stainless steel (304 / 316 ) Portable unit with higher output Double and triple deck unit with different screens can be provided Easy to dismantle for cleaning screens Noiseless, maintenance free unit Features: Heavy duty design Smooth functioning Less maintenance

MICRON INDIA 36INCH SS VIBRO SIFTER

60,000 - 65,000 Per piece

1 Piece (MOQ)

Vibro Sifter Machine

50,000 - 130,000 Per piece

1 Piece (MOQ)

Vibro Sifter Machine

Get Price Quote

Multi Mill Machine, Tablet Coating Machine, Rotary Tablet Machine

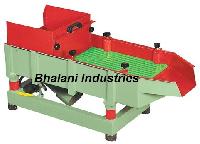

Vibro Separator

Get Price Quote

We are offering vibro separator. bhalani vibro separators are dewlapped to separate ceramic media, parts and water by screening. Vibro seprator is powered by foot mounted vibratory motor. This range of vibro separator is known for saving time and labour as compared to the manual screening. These products are known for their sturdiness and reliability. Separation screen will be fitted with nylon perforated for effective separation of ceramics and parts. All the contact parts are mild steel suitably protected against corrosion. The top screen is removable type & can be replaced for screening of different material. features simple construction & maintenance free. accurate separation & easy to operate. can be added in continues production system rugged heavy duty special vibratory motor.

Vibro Sifter

Get Price Quote

Vibro Separators are circular unitary gyratory screens used to separate mass composition of solids from solids, and for gradation of materials as per particle size, having wide range applications. The structuring of the machine has been designed in order to achieve the multiple plane vibration by suitable assembly of the specially designed Vibratory motor (constructed for this purpose) having eccentric weight at the top and bottom ends of the motor shaft. The motor is mounted vertically at the centre of the screening assembly, on a circular base by means of springs which allow the Unit to vibrate freely. The springs absorb the vibrations and prevent them to be transmitted on the floor. The top weight causes vibration in the horizontal plane which causes the material to move across the screen towards the Periphery. The lower weight acts to tilt the machine which causes vibration in the vertical tangential axis. The angle of lead of the lower weight with relation to the upper weight provides variable control of the screening pattern. Thus the material moves across the screen and also in the vertical and tangential planes enabling maximum screening.

Automatic Vibro Sifter

Get Price Quote

1 Piece (MOQ)

VIBRO SIFTER SIZE AVAILABLE IS 12, 24, 30, 36 & 48.

Vibro Sifter

Get Price Quote

At the initial stages of sourcing raw material and other inputs, we sternly check for the quality used for the same. With the best range of raw material comes the best product. Thus, equal attention is given while sourcing inputs. We follow the globally accepted packaging norms that help us in delivering the products safely. Our professionals ensure that the packing material we use keeps the product safe from external damaging factors.