Volumetric Liquid Filling Machine

Get Price Quote

Semi automatic volumetric liquid filling machines are two head, table top, fully GMP model used to fill variety of liquids. This machine works on the volumetric principle and is fitted with two syringes on the sides. The volume of the machine can be easily adjusted by increasing or decreasing the eccentricity. Motor and gearbox of the liquid filling machines are covered in a SS cabinet.

Automatic groundnut oil filling machine

295,000 Per piece

Best Deals from Volumetric Filling Machine

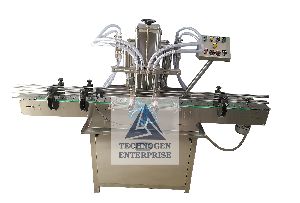

AUTOMATIC 4 Head VOLUMETRIC BOTTLE LIQUID FILLING MACHINE

275,000 - 350,000 Per piece

1 Piece (MOQ)

Automatic 8 Head Volumetric Liquid Filling Machine

Get Price Quote

SIngle Head Piston filler Juice filling machine

45,000 - 100,000 Per piece

1 piece (MOQ)

cGMP Vial Powder Filling Machine

Get Price Quote

Automatic Edible Oil Filling Machine

1,000,000 Per Piece

Ampoule packing machine

Get Price Quote

We offer our clients with ampoule packing machine that is fabricated as per the industrial standards. Ampoule packing machine are available with in-built safety features for long term reliable operation. Further, ampoules Filling and Sealing Machine are also provided in customized specifications to meet the varied needs of the clients. Our range includes the following:- We are instrumental in offering automatic six head ampoule filling and sealing machine, model � ahfs-6. These are highly appreciated by our clients for the sealing pre mechanism and for the feature of no ampoules no filling. We offer precision engineered automatic four head ampoule filling & sealing machine, model ahfs � 4. automatic four head ampoule filling & sealing machines are manufactured using high quality components and are offered in customized solutions as per the needs of the clients. Further, automatic four head ampoule filling & sealing machine are available with a. C. Frequency drive that provides speed control for digital counter. In addition, we offer these with the pre sealing mechanism, which does not require ampoules or filling.

Automatic Volumetric Liquid Filling Machine

Get Price Quote

Rotary Volumetric Filling Sealing Machine

Get Price Quote

1 Piece(s) (MOQ)

Our company counted as an authentic supplier of Rotary Volumetric Filling Sealing Machine in Gujarat. This technically advanced pharmaceutical machine is packed with centralized volume adjustment system, cap chute with additional sensor to protect caps during rotation, individual variable drive for effective handling of speed conveyor, electronic liquid level controller, pneumatically controlled control valve and PLC controlled mechanism to avert dust particles during the operation of this machine. One of the unique features of our Rotary Volumetric Filling Sealing Machine is its efficiency in sealing of filled bottles within a short span of time. As a renowned wholesale supplier in India, we offer Rotary Volumetric Filling Sealing Machine with a reliable and longer life in an affordable price to our customers.

Vegetable Oil Filling Machine

250,000 Per Piece

engine oil filling machine

Get Price Quote

SOLVENT BASED FILLING MACHINE

Get Price Quote

SOLVENT BASED (LIQUID) FILLING AND SEALING MACHINE Basically machine is designed for filling and sealing solvent base ink cartridge. One of the main features of this machine is it does not have any air presence in cartridge. Usually these sealed cartridges are used in flex hoarding. Solvent pour through glass flax mounted on the top of Machine to pre-formed pouch which also mounted in the machine. Finally filled ink pouch sealed after press the foot switch with zero air presence. ALSO KNOWN AS INK POUCH PACKING MACHINE

Automatic Volumetric Liquid Filling Machine

Get Price Quote

KEY FEATURES : ± 1 % Filling accuracy on single dose. No bottle No filling system. Rigid vibration free construction for trouble free performance. Drain tray around machine platform. Pneumatic bottle stopping arrangement. Minimum change overtime, from one size to another container or fill size. OPTIONAL FEATURES : Acrylic cabinet Automatic chain washing system for conveyor belt Nitrogen Flushing Float tank (Holding tank) with or without stirrer PLC Based control Panel

Oil Filling Machine

Get Price Quote

Oil filling machine, It fully works on volumetric principle with easy to use control panel. Oil filling machine setting and accuracy can be easily adjusted on the machine itself. It is featured with adjustable nozzles which are easily manageable and speed can be set in terms of bottle per minute. Adjustment can be made without interrupting filling sequence.

Automatic Volumetric Liquid Bottle Filling Machine

Get Price Quote

The incoming dry bottles containers are placed manually below the feed nozzle and set volume is filled through volumetric cup set fitted with adjustable disc guide. Machine is semi automatic so output will totally depend on operator efficiency. Volumetric cup filling machine is single discharge for dosing system is specially designed to best suit powder/granulate dosing mechanism. Machine is also available with automation features.

Volumetric Filling Machine

Get Price Quote

Shrink Machine, Powder Filling Machine, pedal press selling machine

Mustard Oil Filling Machine

Get Price Quote

Automatic Four Head Vial Filling and Rubber Stoppering Machine

Get Price Quote

AUTOMATIC High Speed LIQUID Vial Filling & VACUUM Rubber Stoppering Machine MODEL: AHVF 4, 6 & 8 Description: High Speed Automatic Vial Filling & Rubber Stoppering Machine suitable for the filling & rubber stoppering of glass vials. Our Automatic Vial Filling & Rubber Stoppering Machine is widely uses in SMALL & large volume injectable preparations. Machine consist automatic feeding, filling, bunging & ejection system all complies as per cGMP requirements. Automatic Vial Filling & Rubber Stoppering Machine can be attached to Vial Washing Machine and Vial Cap Sealing Machine in order to complete online Sterile Vial Filling Line. Machine complies as per GMP requirements. Our standard machine equipped with stainless steel piston pump for the liquid filing, further we can also provide peristaltic pump for higher filling accuracy upon specific customer request. Salient Features: • Suitable for the filling Volume of 2ml to 250ml. • Piston pump/Peristaltic pump aseptic filling. • Filling with accuracy of ±0.5-1% • Filling with accuracy of ±0.5-1%. • All Contact Parts Made from S.S 316L & framework by S.S. 304. • ariable A.C. frequency drive for speed adjustment. • Digital Vial Counter for counting production output. • In-feed Turn Table/ Unscrambler for automatic feeding of objects. • On-line Mechanism. • “No Vial - No Filling” system. • “No Vial - Machine Stop” system. • IQ/OQ documentation can be provided Process Operation: The incoming dry vial (sterilized and siliconised) are fed through the unscrambler and suitably guided on the moving delrin slat conveyor belt at the required speed of the correct placement below filling unit. The filling unit consists of Filling Head, Syringes & Nozzles which are used for liquid filling. The syringes are made of S.S. 316 construction and both, glass as well as S.S. syringes can be used. A Star Wheel is provided which holds the vial during filling operation. A sensor is provided for 'No Vial-No Filling' operation. Syringes are mounted on eccentric block and driving through bottom main gear box. Volume can be either increased or decreased by increasing or decreasing stroke length of piston as per filling size. Syringes is having non return valve for sucking and delivering situation to avoid volume variation. Liquid will reach to filling nozzles through silicon transparent pipe. Nozzle will be having Up and Down movement with help of cam mechanism and it will come down when vial will be hold by starwheel for filling operation and starts filling when it starts to move up and after completion of filling operation, starwheel delivers six vials together on conveyor for rubber stoppering operation.

Automatic Volumetric Liquid Bottle Filling Machine

Get Price Quote

SALIENT FEATURES + 1% Filling Accuracy on single dose. Rigid vibration free construction for trouble free performance. S.S elegantly matt finished body. Elegant and easy control panel for total control on operation. Minimum charge overtime, from one size to another container or fill size. Automatic washing of conveyor belt[ optional. No container No filling system – to avoid spillage. Pneumatic control bottle stopper. cGMP Model.