Vial Filling Machine

Get Price Quote

CPLFRS Automatic Vial Filling with Rubber Stoppering Machine is a compact model used for filling and rubber Stoppering of Injectable liquid into vials. The incoming dry vial (sterilized) are fed through the Un-scrambler and suitably guided on the moving delrin slat conveyor belt at the required speed of the correct placement below Filling unit.

Automatic Volumetric Liquid Bottle Filling Machine

Get Price Quote

SALIENT FEATURES + 1% Filling Accuracy on single dose. Rigid vibration free construction for trouble free performance. S.S elegantly matt finished body. Elegant and easy control panel for total control on operation. Minimum charge overtime, from one size to another container or fill size. Automatic washing of conveyor belt[ optional. No container No filling system – to avoid spillage. Pneumatic control bottle stopper. cGMP Model.

Best Deals from Volumetric Filling Machine

Automatic PFS Filling Machine

6,000,000 Per piece

1 piece (MOQ)

Semi Automatic Volumetric Liquid Filling Machine

75,000 Per Piece

1 Piece (MOQ)

Automatic Pre-Filled Syringe Plunger Rod Insertion and Labelling Machine

Get Price Quote

1 Unit (MOQ)

Automatic Pre-Filled Syringe Plunger Rod Insertion and Labelling Machine Automatic Pre-Filled Syringe Plunger Rod Insertion and Labelling Machine consisting of the main structure covered polycarbonate cabinet and SS 304 pipe, laminar airflow, filling head with individual servo motor, out-feed collection tray, vacuum system, pneumatic components, and electrical panel, AC Drive, PLC & HMI. Syringe Filling Machine & Stoppering Machine loaded on Stainless Steel in-feed hopper. A prefilled syringe manufacturing process machine tray can directly be loaded onto the PFS machine. Duly filled & stoppered syringes delivered on outfeed collection tray without hand touch.

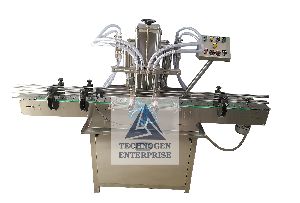

AUTOMATIC 4 Head VOLUMETRIC BOTTLE LIQUID FILLING MACHINE

275,000 - 350,000 Per piece

1 Piece (MOQ)

Four Head Vial Liquid Filling Machine

100,000 - 300,000 Per piece

1 Piece (MOQ)

Automatic Vial Powder Filling Machine

Get Price Quote

4 Head Automatic Volumetric Liquid Filling Machine

225,000 - 275,000 Per Nose

1 piece 2,75,000/-IRS. (MOQ)

Vegetable Oil Filling Machine

250,000 Per Piece

Automatic Flowmetric Lubricant Oil Filling Machine

Get Price Quote

cGMP Vial Powder Filling Machine

Get Price Quote

VOLUMETRIC VIAL BOTTLES FILLING MACHINE

Get Price Quote

Automatic volumatric vial bottles filling machine is working on the volumetric principle. The machine consists of diving nozzles. The machine is made up of stainless steel matt finish body. It is compact and versatile. HOW IT IS SIMPLE AND QUICK : There is a twin pneumatically operated stopper system with feed below and filling nozzles. The conveyor belt moves the container to the filling nozzles. The reciprocating nozzles and stopper system can match for centering of the container below nozzles, to avoid the wastage of the liquid. The nozzle goes upwards from the bottom level to minimize the foaming. The fill size can easily set with a hexagonal bolt, below the syringe. THE FEATURES : Very much accurate, ±1% filling accuracy. Vibration free construction Error code display The platform is provided with drain tray round it, and drip tray under the conveyor The perfect pneumatic arrangement for bottle stopping The conveyor gear box, motor and pneumatic cylinders are provided with the safety guard. To prevent from the short circuit and over load, the MCB is given. For the voltage fluctuation and short circuit in A/C frequency drive there is inbuilt protection, with machine No bottle no filing system Trouble free performance with low maintenance Easy control panel Low friction wear surface, smooth and noiseless conveying. It takes minimum time to change the apparatus The bottle height gauge is adjustable for the quick and easy setting The height of the conveyor belt is adjustable to align with other machine of the line No container no cap arrangement The single A/C drive is synchronizing the platform turret and capping bowl, conveyor and star wheel. The conveyor, star wheel and platform turret is synchronized by the single motor. The S.S. matt finished body S.S. cladding or hard chrome plating of all exposed parts. The UHMW-PE guide profile for low friction wears surface. It is self lubricating leads smooth and noiseless conveying. Depending on the gauges and size of caps, the sealing pressure can varied Noise level and power consumption are very low SPECIAL FEATURES : The washing system of automatic chain for the conveyor belt There is afloat tank( holding tank) with or without stirrer In-built pre-inspection Nitrogen flushing Acrylic cabinet The cover of the conveyor is of acrylic UTILITY REQUIREMENT : Electrical Supply : Three Phase + Neutral + EarthingElectrical Load : 2 KWAir Pressure : 6 bar pressure 0.5 CFM

Glass Vial Liquid Filling Rubber Stoppering Machine

215,000 - 2,850,000 Per Piece

1 Piece (MOQ)

Glass Vial Liquid Filling & Rubber Stoppering Machine is suitable for Round Vials with maximum speed of 240 Vials per minutedepending on nature of Liquids, Vial Neck Size, Fill Volume and Rubber Stopper size. Machine construction in fully Stainless-Steel finish including machine frame structure. Machine with built-in Turn Tables at In-feed and Out-feed with individual drives to match the speed of incoming and outgoing vials for smoother operation. All parts coming in contact with Liquids and Rubber Stoppers are made from SS 316 Materials. Machine also available with vaccumetric type Rubber Stoppering System. Special Features: Total Controls on your figure tips. Servo based filling volume adjustment. Easy to adjust filling volume from PLC screen. Easy to maintain and changing spare part, changing format form for different vial sizes. Suitable for the filling Volume of 2ml to 100ml. Volume adjustment by pic controls. Provision of Manually fine volume adjustment Higher accuracy with higher speed due to servo control continuous motion. Provision of half and full stoppering. Inbuilt Scrambler &Unscr ally or fully stopper filled vials. Vial filling machine shall be equipped with eject collect tray for un stopper Vials. Provision for inert gas purging – pre and post the filling. Rejected without stopper vial shall be store in a safe condition, Vial filling machine shall perform the following functions. Vial half stoppering. Nitrogen purging (pre and post fill). Fallen vial eject, no stopper ejects. Ambler with rejected vial collect facility. Rigid vibration free construction for trouble free performance Pick and place type stoppering machine Vial filling machine shall be equipped with pumps with an accuracy of 0.5 on the fill volume. Suitable for Plain as well as Slotted Stoppers, with the help of change parts High Precision manufactured Syringes (2 Nos.) Servo Motor driven Syringes

Automatic Volumetric Liquid Filling Machine

Get Price Quote

Automatic Edible Oil Filling Machine

1,000,000 Per Piece

Rotary Volumetric Filling Sealing Machine

Get Price Quote

1 Piece(s) (MOQ)

Our company counted as an authentic supplier of Rotary Volumetric Filling Sealing Machine in Gujarat. This technically advanced pharmaceutical machine is packed with centralized volume adjustment system, cap chute with additional sensor to protect caps during rotation, individual variable drive for effective handling of speed conveyor, electronic liquid level controller, pneumatically controlled control valve and PLC controlled mechanism to avert dust particles during the operation of this machine. One of the unique features of our Rotary Volumetric Filling Sealing Machine is its efficiency in sealing of filled bottles within a short span of time. As a renowned wholesale supplier in India, we offer Rotary Volumetric Filling Sealing Machine with a reliable and longer life in an affordable price to our customers.

Semi Automatic Volumetric Filling Machine

100,000 - 130,000 Per piece

1 piece (MOQ)

Ampoule packing machine

400,000 Per Piece

Technical Data • Product Pack : Tablet, Capsules , Soft Gelatine Capsules • Material Uses: Nontoxic thermo formable transparent or opaque Pvc. Pvc with Pepvdc coating. • Lidding Materials: Hard aluminium foil with heat seal able inquire or pvdc coating. • Additional Advantage: Suitable for surgical product, disposable needles, syringes, scalp vein, IV cannula set, vial, ampoules etc.

Ampoule and Vial Filling Machine

Get Price Quote

We are one of the most renowned and well established companies which are also offering its clients one of the finest quality ampoule and vial packing machines. These ampoule and vial packing machines are one of the most efficient and reliable kind of machines which we are not only manufacturing but also are efficiently supplying in different parts of the country. These ampoule and vial packing machines are used for the purpose of packing the medicines and drugs in most efficient and convenient manner. We are offering these ampoule and vial packing machines to our clients at a very reasonable range of prices. Features: Easily affordable Long lasting Easy to use and maintain Low consumption cost Supreme construction

Oil Filling Machine

Get Price Quote

Oil Filling Machine

500,000 Per Piece

Volumetric Liquid Filling Machine

360,000 Per unit

Vial Filling Machine

Get Price Quote

The Automatic Twin Head Volumetric Liquid VialBottle Filling with Rubber Stoppering Machine Model LIQFILL-40IR is suitable for Round Vials and Bottles with maximum speed of 40 Products per minute. The Machine can give Maximum speed of 40 Vials Bottles per minute depending on nature of Liquids, VialBottle Neck Diameter, Fill Volume and Rubber Stopper size. Machine construction in fully Stainless Steel finish including machine frame structure. Machine with built-in Turn Tables at In-feed with individual drives to match the speed of Filling and Stoppering for smoother operation. All parts coming in contact with Liquids and Rubber Stoppers are made from SS 316 and Teflon. Machine suitable for full as well as half stoppering.

Vial Filling And Rubber Stoppering Machine

Get Price Quote

Vial Filling & Rubber Stoppering Machine Manufacturer Vial Liquid Filling and Stoppering Machine is suitable for the liquid filling and rubber stoppering of glass vials. Machine complete in pleasing matt finished stainless steel construction. The basic unit consists of turntable/unscrambler, SS Stat conveyor belt, Highly efficient and precision built S.S. 316 Syringes, non- toxic synthetic rubber tubing and easy reach compact panel. Real time nitrogen purging facility can be offered in filling nozzle. The minimal distance between filling and stoppering units reduces the risk of contamination. The machines are designed for operation in a sterile area and for use under laminar flow protection. The un-scrambler itself has been redesigned to eliminate dead ends and difficult-to-clean spots. The incoming dry vial (sterilized and siliconised) are fed through the unscrambler and suitably guided on the moving delrin slat conveyor belt at the required speed of the correct placement below filling unit. The filling unit consists of Filling Head, Syringes & Nozzles which are used for liquid filling. The syringes are made of S.S. 316 construction and both, glass as well as S.S. syringes can be used. A Star Wheel is provided which holds the vial during filling operation. A sensor is provided

Vial Liquid Filling Machine (R-Fill-4)

Get Price Quote

Salient Features cGMP model.Compact Model.Equipped with PLC System.Individual Vial rack (Instead of Conveyor)Filling volume can be adjusted through PLC for precise filling Suitable for Full & half Stoppering.Outfeed Tray Collection Unit.Individual control for each station through PLC.Magnetic Door interlocks“No Vial No Filling system” to eliminate wastage of costly liquids“No Vial No Rubber Stopper System” to eliminate wastage of Rubber Stopper.“No Vial No Sealing system” to eliminate wastage of Aluminum Seals.“No Rubber Stopper on vial before sealing No sealing system” “No Rubber Stopper in chute machine Stop system”“No Aluminum Seals in chute machine Stop system”Machine is quipped with 3 Modes. (First Mode: Standard Filling, Second Mode: Lyo mode -1, third Mode: Lyo mode – 2)Pressure Testing for Sealing Station (Optional)Auto rejection for no rubber Stopper on vial/ no seal on vial / low or High Sealing Pressure (Optional)

Injectable Volumetric Liquid Vial Filling And Rubber Stoppering Machine

Get Price Quote

Oil Filling Machine

300,000 - 320,000 Per Piece

Oil Filling Machine

Get Price Quote

Oil filling machine, It fully works on volumetric principle with easy to use control panel. Oil filling machine setting and accuracy can be easily adjusted on the machine itself. It is featured with adjustable nozzles which are easily manageable and speed can be set in terms of bottle per minute. Adjustment can be made without interrupting filling sequence.

Automatic Vial Powder Filling Machine

Get Price Quote

For ensuring quality products at buyer's end, we check each and every product at diverse stages including production, packaging and delivery. Obtain the extensive array of products from our well-established inventory located in Ahmedabad(India). Salient Features : Compact cGMP model Machine provide production output up to 240 vials/minute “No Vial, No Filling” system eliminates wastage of costly powder Multiple Dosing System High Volumetric Filling Accuracy of ± 1% of uniform density Injectable powder can be ensured by setting the depth of piston in the port of powder wheel Built-in Rubber Stoppering Unit saves lot of space in the Sterile Area & reduces the length of Laminar Flow Individual drive for the filling & sealing to match the speed of filling & sealing All motors are provided with appropriate contractors and relays for the protection against any overload or jamming Safety clutch system to avoid Vial breakage Variable Frequency Drive for speed control All contact parts are easily removable for mandatory Autoclaving/ Sterilization Digital counter for counting production output