Semi Automatic Volumetric Filling Machine

100,000 - 130,000 Per piece

1 piece (MOQ)

Semi Automatic Volumetric Liquid Filling Machine

225,000 Per Unit

1 Unit (MOQ)

Best Deals from Volumetric Filling Machine

Semi Automatic Volumetric Liquid Filling Machine

75,000 Per Piece

1 Piece (MOQ)

Robotic PFS Filling Machine

9,000,000 Per piece

1 piece (MOQ)

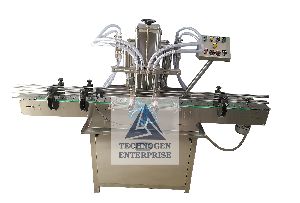

AUTOMATIC 4 Head VOLUMETRIC BOTTLE LIQUID FILLING MACHINE

275,000 - 350,000 Per piece

1 Piece (MOQ)

Automatic Volumetric Liquid Filling Machine

Get Price Quote

Rotary Volumetric Filling Sealing Machine

Get Price Quote

1 Piece(s) (MOQ)

Our company counted as an authentic supplier of Rotary Volumetric Filling Sealing Machine in Gujarat. This technically advanced pharmaceutical machine is packed with centralized volume adjustment system, cap chute with additional sensor to protect caps during rotation, individual variable drive for effective handling of speed conveyor, electronic liquid level controller, pneumatically controlled control valve and PLC controlled mechanism to avert dust particles during the operation of this machine. One of the unique features of our Rotary Volumetric Filling Sealing Machine is its efficiency in sealing of filled bottles within a short span of time. As a renowned wholesale supplier in India, we offer Rotary Volumetric Filling Sealing Machine with a reliable and longer life in an affordable price to our customers.

Vegetable Oil Filling Machine

250,000 Per Piece

Volumetric Bottle Filling Machine

150,000 - 650,000 Per Piece

1 Piece (MOQ)

volumetric liquid filling machine is compact, versatile and enclosed in elegantly matt finish body. this machine provides maximum output up to 200 bottles per min. this machine model is used in pharmaceutical, food, dairy, chemical, cosmetic and beverages industry.the speed of bottle filling machines depends on nature of liquids, container diameter, container height, container neck size and filling volume. machine construction in fully stainless-steel finish including machine frame structure as per cgmp guidelines. machine with optional turn tables at in-feed and out-feed with individual drives to match the speed of incoming and outgoing bottles for smoother operation. all contact parts of machine model are stainless steel 316 only. special features: flow meter for high fill accuracy and repeatability built in plc with color touch screen operation tri-clover joint for easy maintenance no bottle - no fill system, no bottle - machine stop system all contact parts made of ss 316 material with easy removal system machine construction in ss 304 material diving nozzle for foam free filling very high fill accuracy of ± 1 to 1.5 ml for any fill volume up to 250 ml and ± 2 ml above 250 ml pack size. machine also available with option of high fill accuracy of ± 0.5 to 1 ml. suitable for syrup and suspension having higher viscosity. automatic infeed and exit of bottles minimum change over time unique free spinning bottle separator- no pneumatic operation built-in a.c. variable freq. drive system.

VOLUMETRIC VIAL BOTTLES FILLING MACHINE

Get Price Quote

Automatic volumatric vial bottles filling machine is working on the volumetric principle. The machine consists of diving nozzles. The machine is made up of stainless steel matt finish body. It is compact and versatile. HOW IT IS SIMPLE AND QUICK : There is a twin pneumatically operated stopper system with feed below and filling nozzles. The conveyor belt moves the container to the filling nozzles. The reciprocating nozzles and stopper system can match for centering of the container below nozzles, to avoid the wastage of the liquid. The nozzle goes upwards from the bottom level to minimize the foaming. The fill size can easily set with a hexagonal bolt, below the syringe. THE FEATURES : Very much accurate, ±1% filling accuracy. Vibration free construction Error code display The platform is provided with drain tray round it, and drip tray under the conveyor The perfect pneumatic arrangement for bottle stopping The conveyor gear box, motor and pneumatic cylinders are provided with the safety guard. To prevent from the short circuit and over load, the MCB is given. For the voltage fluctuation and short circuit in A/C frequency drive there is inbuilt protection, with machine No bottle no filing system Trouble free performance with low maintenance Easy control panel Low friction wear surface, smooth and noiseless conveying. It takes minimum time to change the apparatus The bottle height gauge is adjustable for the quick and easy setting The height of the conveyor belt is adjustable to align with other machine of the line No container no cap arrangement The single A/C drive is synchronizing the platform turret and capping bowl, conveyor and star wheel. The conveyor, star wheel and platform turret is synchronized by the single motor. The S.S. matt finished body S.S. cladding or hard chrome plating of all exposed parts. The UHMW-PE guide profile for low friction wears surface. It is self lubricating leads smooth and noiseless conveying. Depending on the gauges and size of caps, the sealing pressure can varied Noise level and power consumption are very low SPECIAL FEATURES : The washing system of automatic chain for the conveyor belt There is afloat tank( holding tank) with or without stirrer In-built pre-inspection Nitrogen flushing Acrylic cabinet The cover of the conveyor is of acrylic UTILITY REQUIREMENT : Electrical Supply : Three Phase + Neutral + EarthingElectrical Load : 2 KWAir Pressure : 6 bar pressure 0.5 CFM

Automatic Edible Oil Filling Machine

1,000,000 Per Piece

Automatic Volumetric Liquid Bottle Filling Machine

Get Price Quote

To ensure utmost satisfaction of the buyers, we make sure that the delivery schedule should be properly maintained. Headquartered in Ahmedabad(India), we are acknowledged for providing excellent products domestically. Details : Depends on container size, Fill size, Neck diameter of container, and container, and nature of liquid etc. We can supply as per customer requirements.With help of change parts.

Pre Filled Syringe Filling Stoppering Machine

Get Price Quote

Automatic Prefilled Syringe Filling Machine is suitable for the filling prefilled syringe uses in pharma applications. Machine is compact and provides higher production output. Machine is suitable for application in pharmaceuticals, biotech and Biopharmaceutical industry. Process Operation Syringes loaded on Stainless Steel in-feed hopper. Prefilled syringe tray can directly loaded on to the machine. Syringes move from infeed station to the filling station filling is done by electronic pump. After desired volume filling syringe transfer on stoppering station stoppering is done on well designed manner. Duly filled & stoppered syringes delivered on outfeed collection tray without hand touch.

Volumetric Liquid Filling Machine

360,000 Per unit

Automatic Volumetric Liquid Bottle Filling Machine

Get Price Quote

Operation : Bottles are feed on to in-built Infeed Turn Table, from where it delivered to SS conveyor belt. Conveyor belt transport Bottles to Filling Station. Filling station has Pneumatic bottle stopper for exact bottle neck centering of bottles during filling Operation. Nozzle goes upwards slowly from the bottom level of bottle towards neck during filling to minimize forming adjustable nozzle is reciprocating according to filling dose. The dosing block with a hexagonal bolt, this means different fill size can be set easily within minimum use of time. After liquid filling bottles are delivered to capping/labeling machine conveyor for further operations. Salient Features: cGMP Model Rigid vibration free construction for trouble free performance. SS Elegantly matt-finished body. Elegant and easy control panel for total control on operation. Minimum change over time from one size to another container or fill size. User friendly Machine. Low maintenance cost. All contact parts made of S.S. 316. All contact parts made of S.S. 316. No Bottle – No Filling System. Pneumatic Control Bottle Stopper. Filling Accuracy ± 1 % in single dose (Depends upon fill size & nature of liquids). Machine provided with PLC (OPTIONAL) as per customer requirement.

Volumetric Liquid Filling Machine

Get Price Quote

The Automatic Twin Head Volumetric Liquid VialBottle Filling with CappingPlug Pressing Machine Model LIQFILL-40ic is suitable for Vials and Round or Flat shape Bottles with maximum speed of 40 Products per minute. The Machine can give Maximum speed of 40 Bottles per minute depending on nature of Liquids, Bottle Neck Diameter, Fill Volume and type of Capping or Plugging. Machine can be supplied with Automatic Single Head PPROPPScrew Capping or Pneumatically operated Plug Pressing System.

Volumetric Liquid Filling Machine

Get Price Quote

Semi automatic volumetric liquid filling machines are two head, table top, fully GMP model used to fill variety of liquids. This machine works on the volumetric principle and is fitted with two syringes on the sides. The volume of the machine can be easily adjusted by increasing or decreasing the eccentricity. Motor and gearbox of the liquid filling machines are covered in a SS cabinet.

Automatic Semi Volumetric Filling Machine

Get Price Quote

We are offering automatic semi volumetric filling machine description "gmp" semi automatic volumetric liquid filling machine is precision built on sturdy welded steel frame completely enclose in stainless steel sheet and doors are provided to facilitate the servicing of machine. Working on volumetric principle. The unit is made compact, versatile and enclosed in stainless steel elegantly matt finish body. Operation containers have to place manually below the filling nozzles at platform of machine. Where motor operated syringes fill desire pre set volume in container, bottle guide are provide for precisely match for centering of container below nozzles, to avoid spillage of liquid on container.

Automatic Volumetric Liquid Bottle Filling Machine

Get Price Quote

SALIENT FEATURES + 1% Filling Accuracy on single dose. Rigid vibration free construction for trouble free performance. S.S elegantly matt finished body. Elegant and easy control panel for total control on operation. Minimum charge overtime, from one size to another container or fill size. Automatic washing of conveyor belt[ optional. No container No filling system – to avoid spillage. Pneumatic control bottle stopper. cGMP Model.

Semi Automatic Volumetric Liquid Filling Machine

Get Price Quote

Semi Automatic Twin Head Volumetric Liquid Vial/Bottle Filling Machine Model LIQFILL-20 is suitable for Round or Flat shape Bottles or Vials with maximum speed of 25 Products per minute. The Machine can give speed of 20 to 25 per minute depending on nature of Liquids, Neck Diameter or Vial/Bottle and Fill Volume. Machine suitable for small volume production having multiple products. Machine construction in Stainless Steel finish with Twin Head Operation. All parts coming in contact with Liquids are made from SS 316 Materials. SPECIAL FEATURES: No Product - No Fill System All contact parts are made of SS 316 material with easy removal system for Auto-Claving/Sterilization/cleaning Machine construction in SS 304 material Very High Fill Accuracy Minimum Change Over time

Edible Oil Filling Machine

Get Price Quote

It fully works on volumetric principle with easy to use control panel. Oil filling machine setting and accuracy can be easily adjusted on the machine itself. It is featured with adjustable nozzles which are easily manageable and speed can be set in terms of bottle per minute. Adjustment can be made without interrupting filling sequence.

Vegetable Oil Filling Machine

850,000 Per Set

1 Units (MOQ)

Volumetric Liquid Filling Machine

Get Price Quote

Automatic Volumetric High Speed Twelve Head Bottle Liquid Filling Machine, Model No: ALFT – 251. The machine consist of S.S. slat conveyor belt, reciprocating filling nozzle with self centering devices, S.S. – 316 Syringes, Silicon rubber tubings, easy –reach compact panel and with no container no filling system etc. It is compact, versatile. The un-scrambler has been designed in the machine to eliminate dead ends and difficult to clean spot. All its exposed parts are made of S.S. – 304. It is provided with co-eccentric nozzles, which allow quick and precise setting. Its height can be adjusted to match other machines for efficient synchronization.

Pre Filled Syringe Filling And Stoppering Machine

Get Price Quote

Monoblock pre Filled Syringe filling and Stoppering machine Model - CPPFS is very compact and elegant PLC based GMP model for automatic filling and Stoppering operation of pre filled syringe. Operator has to keep a nest (tray) of 100 pre filled syringes over the SS jig. Then he has to put a jig to filling magazine and start the machine to filled syringes. Operator has to keep a nest (tray) of 100 pre-filled syringes over the SS jig. Then he has to put a plugs tray with suitable stoppers over the SS-316 plug tray. Then after he has to close the evacuation and Stoppering chamber. Now he can start the machine. Automatic Filling cycle start one by one as per the programmed Stoppering cycle mentioned as under. 100 stoppers are plugged into the pre-filled syringes precisely after vacuum hold cycle. Now last cycle of nitrogen flushing with vacuum break completes the Stoppering operation. PROGRAM CYCLE FOR EVACUATION AND STOPPERING Cycle Operation 1 Vacuum evacuation in the chamber 2 Nitrogen Flushing. 3 Vacuum Evacuation repeats. 4 Nitrogen flushing repeats. 5 Vacuum creation with hold. 6 Plunging of stopper inside the pre-filled syringes 7 Nitrogen purging cycle with Vacuum break. SALIENT FEATURES: Model : PFS - 05 is a compact, elegant and matt - finished encompassed with stainless steel (SS-304) Perfect synchronization of PLC based cycle, filling stroke and Syringes to fill volume for 1ml to 5ml Compact and feather-touch MMI control panel for easy control of the machine operation The machine is equipped with easily adjustable leveling legs so foundation is not required. Nitrogen filter is provided pre-filter 0.5u. and final filter is 0.2u. air ex. Is 0.2u. UTILITIES Sterile air and nitrogen Important Requirements 1 Vacuum pump is to be installed outside the sterile area. 2 Silicon tubes are under the scope of customer 3 Water line is required for cooling of vacuum pump chambers PERFECT SYNCHRONIZATION OF PLC

SEMI AUTOMATIC PRE-FILL SYRINGE

Get Price Quote

Suitable For R & d / F & d Purpose & Small Batch Size Production Suitable For Nested Pre-fill Syringes & Nested Stopperes Manual Transfer Of Tub From Filling To Stoppering Unit 21 Cfr Part 11 Compliance Suitable for aqueous & viscous & visco - elastics drugs Filling Accuracy @ (+/-) 0.02ml In 0.2ml Fill Fill Volume Spectrum : 0.2 Ml To 10 Ml (change Part Supported)

Semi automatic 2 Head volumetric filling machine

Get Price Quote

Semi automatic 2 Head volumetric filling machine

Edible Oil Filling Machine

450,000 - 1,250,000 Per 1 pcs

Automatic Volumetric Liquid Bottle Filling Machine works on volumetric principle with diving nozzles. The unit is made compact, versatile and enclosed in stainless steel elegantly matt finish body, consists of S.S. Slat Conveyor, Reciprocating Nozzle with self-centering devices & SS Syringe. No container No filling system arrangement is standard features of the machine. The main drive of the machine and conveyor drive consist of A/c Motor with synchronized variable A/c Frequency Drive.

Pre Filled Syringe Filling Machine

Get Price Quote

blister packaging machine parts

Automatic Volumetric Liquid Filling Machine

Get Price Quote

packaging machineries, Gum Labeling Machine

Volumetric Filling Machine

Get Price Quote

Volumetric Filling Machine, Shrink Machine, pedal press selling machine