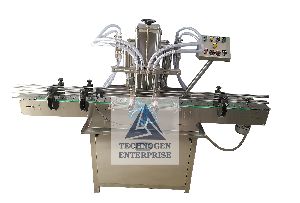

AUTOMATIC 4 Head VOLUMETRIC BOTTLE LIQUID FILLING MACHINE

275,000 - 350,000 Per piece

1 Piece (MOQ)

Sterile Vial Powder Filling Stoppering Machine

Get Price Quote

Best Deals from Volumetric Filling Machine

Lubricating Oil Filling Machine

85,000 - 280,000 Per Unit

1 Piece (MOQ)

Piston Filling Machine

41,500 Per Piece

Edible Oil Packaging Line

1,000,000 - 1,400,000 Per unit

1 Piece (MOQ)

Our quality-driven Edible Oil Packaging Line comprises Linear Filling Machine, Capping Machine, Sticker Labelling Machine, etc. Salient Features Compact and versatile design Sturdy and vibration free design Easy to operate Less maintenance Durable Application Filling Capping Labeling Industry Food processing FMCG

Viscous Piston Filling Machine

Get Price Quote

VISCOUS PISTON FILLING MACHINE FOR WATER, GEL, SHAMPOO, OLIVE OIL FILLING MACHINE, MOTOR OIL FILLER MACHINE This metering pump filling machine is specially made for all materials, such as water, gel, shampoo, oil olive oil, motor oil etc. The machine adopts piston pump and for filling. By adjusting the position pump, it can fill many kinds of the bottles in one filling machine, with quick speed and high precision. The machine can fill different shapes of bottle such as circular, round, flat, square, etc. It is suitable for glass bottle and plastic bottle. The filling capacity can be adjustable, the filling volume can be varied from 500-2500 ml by adjusting the piston pump. An optional diving nozzle mechanism plunges the filling nozzles into the container for increased production speeds without splashing, and we can produce the different filing nozzles for your different speed requirement. Filling volumes are programmable and can be adjusted from the touch screen. FEATURES: It is applicable to different shaped bottles and plastic bottles: plastic,glass bottle and mould bottle. The bottle - in and bottle- out has specialized structure. It doesn't drop bottles or nip bottles.Suitable filling material: This machine adopts piston pump, which is suitable for all kind materials, with highfilling speed and high filling precision. For filling corrosive, the position pump will be made by silicon rubber, Teflon, ceramics and other corrosion resistance materials.Controlling system: The machine adopts full-auto PLC and human-computer touch screen control system. For different volumes adjustment, we set several procedures, mode 1, mode 2, mode 3``` Operators do not need too much complicated adjustments, the filling machine can switch betweenthe three models easily.Different volume adjustment: By adjusting the piston pump, it also can fill all the liquid from 500-2500ml.Bottle position correct device:To ensure the bottles and filling nozzles are in the correct position, we add a special bottles position device to make the whole filling process smooth and stable.No bottle no filling: Filling nozzles. The filling nozzles are specialized made: anti drop. Also, the filling nozzles will come into the bottle bottom, and moving up slowly when filling.Cleaning: The pump uses quick-fit removal Structure, it is easy cleaning and disinfection.

Vegetable Oil Filling Machine

250,000 Per Piece

Edible Oil Filling Machine

250,000 Per Piece

Volumetric Liquid Filling Machine

100,000 - 500,000 Per Piece

1 Bottle (MOQ)

Volumetric Filling Machines find application to fill liquids from low to high viscosity. Volumetric Filling refers to filling liquids by a volume of product, which is its weight or upto a particular level. Equipped with bottom-up fill assembly and adjustable volume control, the speed of filling differs as per the volume to be filled. Ideal for filling liquids with low to medium viscosity, these machines are accurate, are time saving and efficient. Volumetric Filling Machines machines offered by us find their application in various industries for filling liquids from low to high viscosity. The speed of filling differs as per the volume to be filled as the machine is equipped with bottom-up fill assembly and adjustable volume control.

Automatic Edible Oil Filling Machine

1,000,000 Per Piece

Volumetric Liquid Filling Machine

Get Price Quote

We use premium-packaging materials to safeguard our products from mechanical and environmental conditions. For our patrons, we offer customized packaging solutions as well. With our modern transportation facility, timely and safe deliveries are guaranteed with us.Machine Type - Automatic : Automatic Liquid Filling Machine(4 Head) Model no. - SEALFM-40 Machine speed: 40-50 bottle/min depends on bottle size Suitable for use in Cosmetics, Pharmaceuticals, Pesticides, Edible Oil, Lubricants etc. Available in GMP model Also Built-in Digital Product counter Imported Motors and Gears set Accuracy - ± 1 % At one Stroke SS-304 elegantly Matt finished machine Pneumatic stopping arrangements Proximity Sensor for Bottle sensing Available with HMI Display arrangement with PLC controlled Imported PLC for Better Functionality of HMI No bottle, Machine Stop with indication Voltage - 1-Phase, 230V, 50 Hz Product size - Up to 1000 ml Machine size - 1500*1000*800 mm

cGMP Vial Powder Filling Machine

Get Price Quote

Oil Filling Machine

Get Price Quote

Oil Filling Machine

Container Oil Filling Machine

Get Price Quote

Fully Automatic Container Filling Machine is offered by us to clients in bulk. The offered Fully Automatic Container Filling Machine is available in the market in wide range in various specifications. This Fully Automatic Container Filling Machine is extensively used in industrial and commercial applications. The offered Fully Automatic Container Filling Machine is available in the market in various sizes. Fully Automatic Container Filling Machine is known for its high performance. Product details : Machine Type Automatic Brand: NPM Power Consumption 1.8 kw Min Capacity 200 Ml Max Capacity 15 liters Material SS

single head piston filler liquid filling machine

45,000 - 100,000 Per piece

1 piece (MOQ)

Automatic Volumetric Liquid Filling Machine

Get Price Quote

Rotary Volumetric Filling Sealing Machine

Get Price Quote

1 Piece(s) (MOQ)

Our company counted as an authentic supplier of Rotary Volumetric Filling Sealing Machine in Gujarat. This technically advanced pharmaceutical machine is packed with centralized volume adjustment system, cap chute with additional sensor to protect caps during rotation, individual variable drive for effective handling of speed conveyor, electronic liquid level controller, pneumatically controlled control valve and PLC controlled mechanism to avert dust particles during the operation of this machine. One of the unique features of our Rotary Volumetric Filling Sealing Machine is its efficiency in sealing of filled bottles within a short span of time. As a renowned wholesale supplier in India, we offer Rotary Volumetric Filling Sealing Machine with a reliable and longer life in an affordable price to our customers.

Vegetable Oil Filling Machine

225,000 Per Unit

Oil Filling Machine

285,000 Per Piece

Ampoule packing machine

Get Price Quote

We offer our clients with ampoule packing machine that is fabricated as per the industrial standards. Ampoule packing machine are available with in-built safety features for long term reliable operation. Further, ampoules Filling and Sealing Machine are also provided in customized specifications to meet the varied needs of the clients. Our range includes the following:- We are instrumental in offering automatic six head ampoule filling and sealing machine, model � ahfs-6. These are highly appreciated by our clients for the sealing pre mechanism and for the feature of no ampoules no filling. We offer precision engineered automatic four head ampoule filling & sealing machine, model ahfs � 4. automatic four head ampoule filling & sealing machines are manufactured using high quality components and are offered in customized solutions as per the needs of the clients. Further, automatic four head ampoule filling & sealing machine are available with a. C. Frequency drive that provides speed control for digital counter. In addition, we offer these with the pre sealing mechanism, which does not require ampoules or filling.

Oil Filling Machine

230,000 Per Piece

Edible Oil Filling Machine

Get Price Quote

Volumetric Piston Filling Machine

230,000 - 550,000 Per Bag

1 Piece(s) (MOQ)

Essential Oil Filling Machine

Get Price Quote

SPECIFICATIONS : Essential oil filling machine servo system---adjust filling volume on touch screen directly use good material to anti-corrosio. INTRODUCTION : It mat suit for different viscosity of water agent, semi-fluid and paste, it is widely used in the product filling of foodstuff, cosmetics, medicine, grease, daily chemical industry, detergent, pesticide and chemical industry. Using the straight filling way, may be used in the different vessels, needn’t add any parts. TECHNOLOGICAL PARAMETERS : BRAND BHAGWATI Model SBFILL Product to be Filled Essential Oil Fill Volume 40-120bottles/min (for 250ml/8-head) Measurement precision ±1% Cylinder’s sizes 1000ml Working air pressure 6-7kg/m² Net weight 820kg Contour Sizes 2500×1000×2200mm FEATURES : The series machine, its design compact and reasonable, the appearance artistic and scholar. Choosing the international brand of electrical components. The main powered cylinder, chose the Taiwan Airtac double-action cylinder and magnetic switch, the Japanese Mitsubishi PLC computer, photo electricity and Taiwan-manufactured touching screen, ensuring a good quality and lasting steady performance. The machine has a convenient maintenance, needn’t any tools, may easily dismantle, clean and fix adjustment convenient. The measurement’s adjustment, may at first large range adjust to approaching measurement, then micro adjust. Make not to fill when there is not bottle or lack of bottle, ensuring the accurate measurement. May determine the filling-head number and the cylinder volume per the user’s production demand. The 6-head, 8-head and 10-head mat be chosen, the cylinder volume has 25-250ml, 50-500ml, 100-1000ml and 250-2500ml. The whole machine has speed-adjustable bottle-conveying tape, high strength stainless steel framework, firm and durable. Considering the different viscosity of user’s material especially set a filling suffocated valve of preventing drop and preventing feathering, as well as a descending filling lift system. In order to make the material-falling aim at the bottle mouth accurately, designed a horizontal bottle-aiming fixture device, ensuring the aim’s correct. Because of the complicated material varieties, the machine set a weight filling program to fix the sprue parameter, for the thin liquid, may use the atmospheric timing filling way to decrease production cost ad to enhance the production speed. The system needs not add any parts, may decrease the equipment’s repeated investment, and realize the one-machine multi-use. The machine’s filling system used the chuck quick-fixing hygiene joint. The cylinder’s whole body, from to top to the bottom, needn’t any tools, may easily dismantle, clean and fix. Its structure design simple, operation maintenance convenient.

Oil Filling Machines

Get Price Quote

Oil Filling Machine

325,000 Per unit

Automatic groundnut oil filling machine

295,000 Per piece

Ampoule packing machine

Get Price Quote

Input Specification:- Ampoule Dia : 9 mm to 22 mm, Ampoule Height : 60mm to 125 mm. Conveyor Height:- 800 ± 50 mm or as per the requirement

Edible Oil Filling Machine

170,000 Per Piece

1 Piece(s) (MOQ)

Automatic Grade Automatic Model No. SEALFM-40 Capacity (bottlesmin) 40 Driven Type Electric, Mechanical Dimension(L*W*H) 2000*1000*800 Power Consumption (Kw) 2KW Voltage (V) 230 Brand Shiv Engineering 1) Volumetric pneumatic - Piston Filling Technology. 2)Fills Pharma Liquid, Pesticides, Oil, Water, Lubricants, Shampoo, Hand wash etc. 3) Special heat resistant cylinders and jacketed hopper for hot filling. 4) Fills from 100ml to 1000ml and upto 10liters with maximum accuracy. 5) Special stirrer in the hopper. 6) No change parts and very less maintenance. 7) PLC control system. 8) Diving Nozzle Mechanism avoids foaming and spillage. 9) Anti-drip system helps in keeping the filling area clean. Features : Eazy to operate. Accurate dimension. Low Maintenance.

Automatic Four Head Vial Filling and Rubber Stoppering Machine

Get Price Quote

AUTOMATIC High Speed LIQUID Vial Filling & VACUUM Rubber Stoppering Machine MODEL: AHVF 4, 6 & 8 Description: High Speed Automatic Vial Filling & Rubber Stoppering Machine suitable for the filling & rubber stoppering of glass vials. Our Automatic Vial Filling & Rubber Stoppering Machine is widely uses in SMALL & large volume injectable preparations. Machine consist automatic feeding, filling, bunging & ejection system all complies as per cGMP requirements. Automatic Vial Filling & Rubber Stoppering Machine can be attached to Vial Washing Machine and Vial Cap Sealing Machine in order to complete online Sterile Vial Filling Line. Machine complies as per GMP requirements. Our standard machine equipped with stainless steel piston pump for the liquid filing, further we can also provide peristaltic pump for higher filling accuracy upon specific customer request. Salient Features: • Suitable for the filling Volume of 2ml to 250ml. • Piston pump/Peristaltic pump aseptic filling. • Filling with accuracy of ±0.5-1% • Filling with accuracy of ±0.5-1%. • All Contact Parts Made from S.S 316L & framework by S.S. 304. • ariable A.C. frequency drive for speed adjustment. • Digital Vial Counter for counting production output. • In-feed Turn Table/ Unscrambler for automatic feeding of objects. • On-line Mechanism. • “No Vial - No Filling” system. • “No Vial - Machine Stop” system. • IQ/OQ documentation can be provided Process Operation: The incoming dry vial (sterilized and siliconised) are fed through the unscrambler and suitably guided on the moving delrin slat conveyor belt at the required speed of the correct placement below filling unit. The filling unit consists of Filling Head, Syringes & Nozzles which are used for liquid filling. The syringes are made of S.S. 316 construction and both, glass as well as S.S. syringes can be used. A Star Wheel is provided which holds the vial during filling operation. A sensor is provided for 'No Vial-No Filling' operation. Syringes are mounted on eccentric block and driving through bottom main gear box. Volume can be either increased or decreased by increasing or decreasing stroke length of piston as per filling size. Syringes is having non return valve for sucking and delivering situation to avoid volume variation. Liquid will reach to filling nozzles through silicon transparent pipe. Nozzle will be having Up and Down movement with help of cam mechanism and it will come down when vial will be hold by starwheel for filling operation and starts filling when it starts to move up and after completion of filling operation, starwheel delivers six vials together on conveyor for rubber stoppering operation.