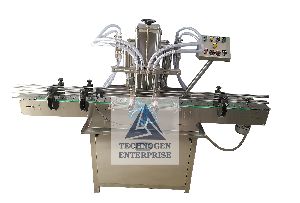

AUTOMATIC 4 Head VOLUMETRIC BOTTLE LIQUID FILLING MACHINE

275,000 - 350,000 Per piece

1 Piece (MOQ)

Automatic Edible Oil Filling Machine

1,000,000 Per Piece

Best Deals from Volumetric Filling Machine

Vegetable Oil Filling Machine

250,000 Per Piece

Sterile Vial Powder Filling Stoppering Machine

Get Price Quote

Piston Filling Machine

41,500 Per Piece

Vegetable Oil Filling Machine

Get Price Quote

We are leading manufacturer and exporter of Vegetable Oil Filling Machine and our product is made up of good quality. Vegetable Oil Filling Machineoffered comprise the latest technology based filling equipment that features advanced PLC microcomputer programmable control so as to allow precise working performance. Finding extensive use in food industry sector, these machines provide for accurate filling measurement with no bubble filling. Product details : Capacity 50 to 1000 ml TMachine Type :Automatic, Semi-Automatic Dimension(L*W*H) 2600x1800x2500mm Features : Suits filling of all kinds of bottles from 50 to 1000 ml Short filling circle High production capacity Touch operation based color screen for controlling operation procedures. Edible Oil Pouch Packing Machine We are the manufacturer, Exporter and supplier of highly efficient Edible Oil Pouch Packing Machine. It is used for the packaging of edible oil and is manufactured from premium quality components and modern technology. Features : Easy operation Low maintenance High performance Specification : Power: 1.5KW Packaging Type: Bags Application:Apparel,Beverage,Chemical,Commodity,Food,Medical Packaging Material: Plastic

Automatic Volumetric Liquid Filling Machine

Get Price Quote

Edible Oil Packaging Line

1,000,000 - 1,400,000 Per unit

1 Piece (MOQ)

Our quality-driven Edible Oil Packaging Line comprises Linear Filling Machine, Capping Machine, Sticker Labelling Machine, etc. Salient Features Compact and versatile design Sturdy and vibration free design Easy to operate Less maintenance Durable Application Filling Capping Labeling Industry Food processing FMCG

Mustard Oil Filling Machine

Get Price Quote

Dispensing volume with this Automatic Inline Positive Displacement Pump Filler is accurately measured by reading the revolutions of the pump and motor assembly. Fill rates can be modulated by varying the motor speeds with ramp up and ramp down capability guaranteed to result in a clean end to your fill cycle ,Our fillers range from 2 – 24 head Positive Displacement fillers, as well as multi-lane machines with pumped capacity. These Positive Displacement fillers employ highly reliable positive displacement pumps to quickly and accurately fill any product. The pumps are controlled via the HMI screen which is available as either push button or touch screen, utilizing our highly effective “Recipe” system which can be programmed to store numerous sets of settings for the various products, and packaging sizes. Salient Features Accuracy – Easy to use and easy to adjust the volume dispensed with a simple control setting Control of both pump speed and position during the fill cycle guarantees accurate filling Changeover is quick with ability to store multiple programs in the PLC controller All machine adjustments are designed for fast changes Customization – Construction materials, contact parts, pump style, number of fill heads, and other options allow simple customization to your filling needs True positive displacement filling provides increased filling accuracy with products prone to viscosity change Variable fill rate control (ramp up/down) prevents foam and produces a clean accurate end to the fill cycle Diving nozzle Positive shut off valve x 2, 4, 6 to 24 nozzle etc. Filling Speed 2 HEAD - 10-12 Fills Per Minute @ 1Ltr 4 HEAD - 20-24 Fills Per Minute @ 1Ltr 6 HEAD – 30-36 Fills Per Minute @ 1Ltr 8 HEAD - 40-48 Fills Per Minute @ 1Ltr The filling nozzles are fitted with a pneumatically operated positive shut off valve to prevent any dripping from within the nozzles.

Single Head Piston Filler Honey Filling Machine

50,000 - 70,000 Per piece

1 piece (MOQ)

Ampoule packing machine

Get Price Quote

We offer our clients with ampoule packing machine that is fabricated as per the industrial standards. Ampoule packing machine are available with in-built safety features for long term reliable operation. Further, ampoules Filling and Sealing Machine are also provided in customized specifications to meet the varied needs of the clients. Our range includes the following:- We are instrumental in offering automatic six head ampoule filling and sealing machine, model � ahfs-6. These are highly appreciated by our clients for the sealing pre mechanism and for the feature of no ampoules no filling. We offer precision engineered automatic four head ampoule filling & sealing machine, model ahfs � 4. automatic four head ampoule filling & sealing machines are manufactured using high quality components and are offered in customized solutions as per the needs of the clients. Further, automatic four head ampoule filling & sealing machine are available with a. C. Frequency drive that provides speed control for digital counter. In addition, we offer these with the pre sealing mechanism, which does not require ampoules or filling.

Oil Filling Machine

230,000 Per Piece

Rotary Volumetric Filling Sealing Machine

Get Price Quote

1 Piece(s) (MOQ)

Our company counted as an authentic supplier of Rotary Volumetric Filling Sealing Machine in Gujarat. This technically advanced pharmaceutical machine is packed with centralized volume adjustment system, cap chute with additional sensor to protect caps during rotation, individual variable drive for effective handling of speed conveyor, electronic liquid level controller, pneumatically controlled control valve and PLC controlled mechanism to avert dust particles during the operation of this machine. One of the unique features of our Rotary Volumetric Filling Sealing Machine is its efficiency in sealing of filled bottles within a short span of time. As a renowned wholesale supplier in India, we offer Rotary Volumetric Filling Sealing Machine with a reliable and longer life in an affordable price to our customers.

Oil Filling Machine

285,000 Per Piece

cGMP Vial Powder Filling Machine

Get Price Quote

Liquid Vial Filling With Rubber Stoppering Machine

Get Price Quote

Harsiddh engineering is reputed for providing small, easy to use, economical and high quality vial filling and stoppering machines. Our six head filling and sealing machine is specially designed to cater for all pharmaceutical, R&D and other chemical filling of sterile vials. The equipment handles vials ranging in various capacities. Our Vial Liquid Filling with Rubber Stoppering Machine has CE certification. The machine fills liquid into the vial and then adds a rubber stopper. The device receives sterile vials that pass through a conveyor belt and then a star wheel that holds vials in position when filling. Special sensors are mounted to ensure that no vial, no filling condition is achieved. The filling process is achieved through the syringes and nozzles. After completion of the filling process, the star wheel exit mechanism delivers the six vials to the vibratory rubber stoppering system via a conveyor for sealing and finally exits vials after sealing. The contact parts are manufactured using corrosion free stainless steel SS 316 and made according to cGMP specifications. Piston pumps are used during filling and the volume can be adjusted by altering the stroke length. Syringes have non-return valve to ensure that the sucking and delivery process have no volume variation. Liquid Vial Filling With Rubber Stoppering Machine is compact and free of vibrations. It uses a single synchronized motor to drive all units in tandem and ensure smooth operation. The stopper and vials can be heated and cleaned through pre and post nitrogen flushing system. Silent Features Suitable for 02ml to 100ml Glass Vials. Pre & Post nitrogen flushing unit. In feed & Out feed turn table (Un-scrambler and Scrambler). Unit consist of in feed of vials, nitrogen flushing, liquid filling, rubber stoppering and out feed of vials (monoblock model). Piston pump filling (Volumetric). High filling accuracy. Diving nozzle systems for foam free filling. Suitable for 13mm, 20mm, 28mm and 32mm rubber stopper size. Contact parts prepared from AISI 316 material. Digital counter arrangement for filled vials (optional). No Vial No Filling” machine stop systems. No Vial No Stopper” machine stop systems. Synchronized speed of turn table, conveyor and filling pump drive. Suitable for glass as well as plastic vials filling and stoppering. Protection clutch mounted in case of overcrowding. Linear left to right direction. On line mechanism.

Automatic Ampoule Paper Rondo Tray Packing Machine

Get Price Quote

Automatic Ampoule Paper Rondo Tray Packing Machine MODEL: AHRP 40C SUITABLE FOR “C” & “I” TYPE PAPERS TRAYS PUTTING INTO OPERATION Basic units consist of a rondo tray hopper, a denesting station, a product hopper, a rotary filling stations, an inserting wheel, and controls switches. The machine should be used for Ampoules to be packed in rondo trays for which it has been fitted with. The nested trays are placed directly in the rondo tray hopper in the same position as received from the suppliers. Filled and labeled ampoules are placed in the product hopper in vertical position. Now, operate the machine for a short time, by pressing inching Push Button with a view to obtain uniform packing of ampoules in to rondo trays.. The dog chain moves out each pair of nested rondos and transfers them to the denesting station where they are separated and positioned face up. The rotary transfer wheel picks up a preselected number of ampoules and drops them in the rondo flutes. The ampoules next are firmly inserted in to the flute of the rondo by means of the inserting wheel. Direction Of The Operation Will Be Left To Right. Machine occupies very little floor space as compare to hand packing. Machine occupies very little floor space as compare to hand packing. Very simple in operation. Size changes take less than fifteen minutes and require no special tools. Machines efficiency allows short runs and frequent changes. If ampoules placement found satisfactory, the machine is put into operation. Now push green push button for continuous operations. Size of Ampoules: The machine used to pack Ampoules from 10mm to 17mmin diameter in to rondo trays in the horizontal position . The height of the round Ampoules should be proportional to the diameter. In the event of unusual height, kindly get the Ampoules examined at our works before putting the machine into operation. Size of rondo trays. The machine is suitable for following dimensions of the rondo trays. Change parts: The machine is fitted with the change-parts suitable for any one size of Ampoules as per the order and samples tried out. The machine can be pre-set for the different size of Ampoules and rondos trays with change-parts. the changes in star wheel depends on change in ampoules diameters, changes in numbers of fills per rondo or changes in rondo dimensions. Salient Feature: Flap opening station, over printing device, flap closing station & gumming station Airjet for flap opening Online label applicator with online batch printing units for c types paper trays No rondo no object Ac drives Digital counter

coolant oil liquid filling machine

Get Price Quote

Filling Accuracy on Single dose. 4 bottle fill in singal dose Filling range : 50 ml to 250 ML Filling Per minute bottles 12 to 16 AllMachine,Body Is An S.S STRUCTURE

Vial Filling Machine

Get Price Quote

Bhagwati tablet counting and filling machine adopts advanced vibration and multi-channel feeder, computer control, dynamic scan counting, transfer the bottle automatically, system test automatically. The machine With Stop automatically function and other advanced technology. This machine designed with GMP standard. Compose the light, electric machinery to one set, which is suitable for tablet or capsule counting and filling in pharmaceutical or food business.

Volumetric Cup Filler

Get Price Quote

Semi Automatic Volumetric Liquid Bottle Filling Machine

Get Price Quote

APPLICATION & PROCESS : Semi Automatic Volumetric Liquid Bottle Filling Machine works on volumetric principle with syringe & piston & nozzle. It is used to fill liquid in bottle in pharmacy, food, dairy, agro chemicals, Beverages industries. The unit is made compact, versatile and enclosed in stainless steel elegantly matt finish body, consists of, drive unit with gear motor, eccentric drives, Syringe piston assembly, Reciprocating Nozzle with self-centering devices. Bottle is manually loaded in position for filling and unloaded after filling. SALIENT FEATURES : Semi automatic with filling range from 5 ml to 1000 ml with the help of change parts. Accuracy ± 1 % in single doze. Three different speeds depending upon capacity of bottles. Body covered with SS sheet. All contact parts SS316. A unit to fill variety of liquid and can be used for various type of containers. Minimum change over time from one size to another container or fill size.

Automatic Volumetric Liquid Bottle Filling Machine

Get Price Quote

The incoming dry bottles containers are placed manually below the feed nozzle and set volume is filled through volumetric cup set fitted with adjustable disc guide. Machine is semi automatic so output will totally depend on operator efficiency. Volumetric cup filling machine is single discharge for dosing system is specially designed to best suit powder/granulate dosing mechanism. Machine is also available with automation features.

Volumetric Liquid Filling Machine

275,000 Per Piece

1 Piece(s) (MOQ)

Automatic groundnut oil filling machine

295,000 Per piece

Ampoule packing machine

Get Price Quote

Input Specification:- Ampoule Dia : 9 mm to 22 mm, Ampoule Height : 60mm to 125 mm. Conveyor Height:- 800 ± 50 mm or as per the requirement

Vial Filling and Sealing Machine Adinath International

500,000 - 1,000,000 Per Piece(s)

Adinath International offers Vial Filling and Sealing Machine for filling, rubber stoppering and cap sealing of glass vials including ampoule filler sealer, ampoule filling machine for single head, double head, four head, six head and eight head, ampoule vial jet washing machine, ampoule inspection machine, ampoule labeling machine, double and four stroke ampoule filling machine, glass ampoule filling machine, cosmetic ampoule filling machine and powder filling machine from a leading manufacturer and exporter of pharmaceutical machinery in Ahmedabad, India.

Volumetric Filling Machine

Get Price Quote

Semi automatic volumetric liquid filling machines are two head, table top, fully GMP model used to fill variety of liquids. This machine works on the volumetric principle and is fitted with two syringes on the sides. The volume of the machine can be easily adjusted by increasing or decreasing the eccentricity. Motor and gearbox of the liquid filling machines are covered in a SS cabinet. Volumetric liquid filling machines is available in varied dimension and capacities. The machine consists of Reciprocating Filling, Driving type Nozzle, multi dose filling system, PLC control panel, Container Platform, syringe Holders, HDPE Tubes and Piles and on line starter.

Automatic Vial Filling Machine

Get Price Quote

Output 80 – 100 vials / minute suitable for 5 ml to 30 ml vials depending upon volume and viscosity of liquid fitted with part suitable for any one size of vial & stopper size. Features M. S Structure & SS. – 304 Cladding. For frame and top plate. Individual gear box for each unit. No belt drive. Separate A. C. Frequency drive speed control. NO stopper no vial machine stop system. Automatic rubber stopering and Aluminum cap by vibratory.

SOLVENT BASED FILLING MACHINE

Get Price Quote

SOLVENT BASED (LIQUID) FILLING AND SEALING MACHINE Basically machine is designed for filling and sealing solvent base ink cartridge. One of the main features of this machine is it does not have any air presence in cartridge. Usually these sealed cartridges are used in flex hoarding. Solvent pour through glass flax mounted on the top of Machine to pre-formed pouch which also mounted in the machine. Finally filled ink pouch sealed after press the foot switch with zero air presence. ALSO KNOWN AS INK POUCH PACKING MACHINE

Ampoule packing machine

Get Price Quote

These ampoule filling machines are manufactured using high quality components and are offered in customized solutions as per the needs of the clients. Further, these are available with A. C. Frequency drive that provides speed control for digital counter. In addition, we offer these with the pre sealing mechanism, which does not require ampoules or filling. The machine built on principle of Slant travel of ampoules while filling and sealing. to take care of wide variation of ampoule neck dimensions, thicknesses and ovality of available in globe ampoules.