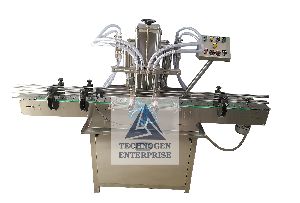

AUTOMATIC 4 Head VOLUMETRIC BOTTLE LIQUID FILLING MACHINE

275,000 - 350,000 Per piece

1 Piece (MOQ)

Volumetric Liquid Filling Machine

Get Price Quote

Best Deals from Volumetric Liquid Filling Machine

Automatic Volumetric Liquid Filling Machine

210,000 - 550,000 Per Piece

1 Piece (MOQ)

Automatic Volumetric Liquid Bottle Filling Machine works on volumetric principle with diving nozzles. The unit is made compact, versatile and enclosed in stainless steel elegantly matt finish body, consists of S.S. Slat Conveyor, Reciprocating Nozzle with self-centering devices & SS Syringe. No container No filling system arrangement is standard features of the machine.

Automatic Volumetric Liquid Filling Machine GMP Model

Get Price Quote

Automatic Volumetric Liquid bottle filling machine, which is made compact, versatile and enclosed in stainless steel elegantly matt finish body. This unit works on volumetric principal and reciprocating self-centring device. OPERATION : Nozzle goes upwards slowly from the bottom level of bottle towards neck during filling to minimize forming adjustable nozzle is reciprocating according to filling dose The dosing block with a hexagonal bolt, this means different fill size can be set easily within minimum of time. The main drive consists of a helical gearbox driven by A/c motor & through controlled by an Ac frequency drive. The speed can be set in terms of bottles per minute. The conveyor drive consists of a hallow shaft, geared motor controlled by an Ac frequency drive. A knob can set the speed of conveyor. SALIENT FEATURES The unit is made compact & versatile S.S. Slat conveyor. S.S. Elegantly Matt Finished Body No Container No filling system. Reciprocating Filling nozzle with self centring device. Variable A/c Frequency Drive. Pneumatically operated bottle stopper

Automatic Volumetric Liquid Filling Machine

280,000 - 450,000 Per Piece

1 Piece (MOQ)

The excellence-driven Automatic Volumetric Liquid Filling Machine comprises main structure, product transmission belt with an adjustable guide, safety acrylic cover. Pneumatic/ Mechanical bottle stopping facility, nozzle & syringes, electrical panel, motor, sensor, AC drive & mains for performing On/Off functions. Salient Features Sturdy vibration free design Minimum changeover time Drain tray around the machine platform Emergency On/ Off Easy to install and use Application Filling Industry Pharmaceuticals Beverages FMCG Food processing

Automatic Volumetric Liquid Filling Machine

Get Price Quote

Automatic Four Head Liquid Filling Machine

Get Price Quote

Our Automatic Four Head Liquid Filling Machines are endowed with enough power to fill all kinds of free-flowing powders in a foolproof manner. These machines are sturdily built and are designed to deliver hassle-free performance. They are also appreciated for low maintenance cost. We are one of the topmost Manufacturers and Suppliers of Automatic Four Head Liquid Filling Machines in Gujarat. We can offer the machine is custom specifications and feature set. Other Details : + 0.5 to 1% filling accuracy on single dose Rigid vibration free construction for trouble free performance S.S. elegantly matt finished body Elegant and easy control panel for total control on operation Minimum changeover time, from one size to another container or fill size Automatic washing of conveyor belt (Optional) Reciprocating filling nozzle with self-cantering device to avoid foaming The unit is made compact & versatile-as per GMP norms No container no filling system-to avoid spillage Synchronized A.C. drives for conveyor & main drive Pneumatic control bottle stopper/Mechanical bottle control

Volumetric Liquid Filling Machine

Get Price Quote

We use premium-packaging materials to safeguard our products from mechanical and environmental conditions. For our patrons, we offer customized packaging solutions as well. With our modern transportation facility, timely and safe deliveries are guaranteed with us.Machine Type - Automatic : Automatic Liquid Filling Machine(4 Head) Model no. - SEALFM-40 Machine speed: 40-50 bottle/min depends on bottle size Suitable for use in Cosmetics, Pharmaceuticals, Pesticides, Edible Oil, Lubricants etc. Available in GMP model Also Built-in Digital Product counter Imported Motors and Gears set Accuracy - ± 1 % At one Stroke SS-304 elegantly Matt finished machine Pneumatic stopping arrangements Proximity Sensor for Bottle sensing Available with HMI Display arrangement with PLC controlled Imported PLC for Better Functionality of HMI No bottle, Machine Stop with indication Voltage - 1-Phase, 230V, 50 Hz Product size - Up to 1000 ml Machine size - 1500*1000*800 mm

Volumetric Liquid Filling Machine

100,000 - 500,000 Per Piece

1 Bottle (MOQ)

Volumetric Filling Machines find application to fill liquids from low to high viscosity. Volumetric Filling refers to filling liquids by a volume of product, which is its weight or upto a particular level. Equipped with bottom-up fill assembly and adjustable volume control, the speed of filling differs as per the volume to be filled. Ideal for filling liquids with low to medium viscosity, these machines are accurate, are time saving and efficient. Volumetric Filling Machines machines offered by us find their application in various industries for filling liquids from low to high viscosity. The speed of filling differs as per the volume to be filled as the machine is equipped with bottom-up fill assembly and adjustable volume control.

Automatic Four Head Liquid Bottle Filling Machine

Get Price Quote

AUTOMATIC LIQUID BOTTLE FILLING AND ROPP CAP SEALING MACHINE MODEL: AHBF 4 Salient Features: • “No Bottle - No Fill" system. • All contact parts made of SS316 material with Autoclaving/Sterilization/Cleaning. • FMachine construction in SS 304 material. • Diving Nozzle for Foam free filling. • With Fill Accuracy. • Automatic In-feed and Exit of Bottles. • Minimum Change Over time. • Digital counter. • Built-in A.C. Variable Frequency Drive System. Process Operation: Bottles are feed on to in-built Infeed turn table, from where it delivered to SS conveyor belt. Conveyor belt transport bottles to filling station. Filling station has mechanical bottle stopper for exact bottle neck centering of bottles during filling operation. Nozzle goes upwards slowly from the bottom level of bottle towards neck during filling to minimize forming adjustable nozzle is reciprocating according to filling dose. The dosing block with a hexagonal bolt, this means different fill size can be set easily within minimum use of time. After liquid filling bottles are delivered to capping/labeling machine conveyor for further operations.

Volumetric Liquid Bottle Filling Machine

Get Price Quote

Volumetric Liquid Filling Machine

275,000 Per Piece

1 Piece(s) (MOQ)

Volumetric Liquid Filling Machine

Get Price Quote

Automatic Volumetric Liquid Bottle Filling Machine work on volumetric principle with diving nozzles. The unit is made compact, versatile and enclosed in stainless steel elegantly matt finish body, of S.S Slat Conveyor, Reciprocating Nozzle with self-cantering devices & SS Syringe. No container the main drive of the machine and conveyor drive consist of AC Motor with synchronized variable Ac Frequency drive.

Volumetric Liquid Filling Machine

Get Price Quote

Semi automatic volumetric liquid filling machines are two head, table top, fully GMP model used to fill variety of liquids. This machine works on the volumetric principle and is fitted with two syringes on the sides. The volume of the machine can be easily adjusted by increasing or decreasing the eccentricity. Motor and gearbox of the liquid filling machines are covered in a SS cabinet.

Semi Automatic Volumetric Liquid Bottle Filling Machine

Get Price Quote

APPLICATION & PROCESS : Semi Automatic Volumetric Liquid Bottle Filling Machine works on volumetric principle with syringe & piston & nozzle. It is used to fill liquid in bottle in pharmacy, food, dairy, agro chemicals, Beverages industries. The unit is made compact, versatile and enclosed in stainless steel elegantly matt finish body, consists of, drive unit with gear motor, eccentric drives, Syringe piston assembly, Reciprocating Nozzle with self-centering devices. Bottle is manually loaded in position for filling and unloaded after filling. SALIENT FEATURES : Semi automatic with filling range from 5 ml to 1000 ml with the help of change parts. Accuracy ± 1 % in single doze. Three different speeds depending upon capacity of bottles. Body covered with SS sheet. All contact parts SS316. A unit to fill variety of liquid and can be used for various type of containers. Minimum change over time from one size to another container or fill size.

Semi Automatic Volumetric Filling Machine

80,000 - 110,000 Per 1

1 Set(s) (MOQ)

Volumetric Liquid Bottle Filling Machine

Get Price Quote

SALIENT FEATURES No Bottle - No Fill System, No Bottle - Machine Stop System. All contact parts made of SS316 material with easy removal system for Autoclaving/Sterilization/Cleaning.. Machine construction in SS 304 material. Diving Nozzle for Foam free filling. Very High Fill Accuracy. Automatic In-feed and Exit of Bottles. Minimum Change Over time. Unique Free Spinning Bottle Separator- No pneumatic operation. Built-in A.C. Variable Frequency Drive System. TECHNICAL SPECIFICATION Product Rate : 120 to 200 Containers/Min (Two Head)60 to 100 Containers/Min (Four Head)90 to 150 Containers/Min. (Six Head)30 to 60 Containers/Min (Eight Head) Power Specification : 2 H.P., 3 Phase, 4 Wire System, 50 Hz. Filling Range : 30 ml to 1000 ml with the help of suitable change parts. Optional Accessories : Programmable Logic Control (System) with MMIAluminum Profile Cabinet covering full machine Overall Dimension : 1830mm (L) X 900mm (W) X 1680mm (H)Net Weight: 650 Kgs Gross Weight: 875 Kgs

Four Head Vial Liquid Filling Machine

Get Price Quote

We are engaged in fabricating and exporting of Four Head Vial Liquid Filling Machine Model No.AEVLF -80, which has all its exposed parts of S.S. 304, matt finished avoiding any reflection for achieving the most concentration and efficiency of the Four Head Vial Liquid Filling Machine. Further, each individual Four Head Vial Liquid Filling Machine required for autoclaving/sterilization can be removed easily. Features: All exposed parts are of co-eccentric nozzles allow very quick and precise setting and making unit compact and manageable Crafted S.S. holders, lapped glass as well as S.S. syringes and piston and precision Built valve system for achieving very high accuracy in fill size and drip proof performance Precise setting and accuracy can be easily adjusted on the machine itself No vial- no stoppers - no filling system Easy reach compact panel provides ease and operation Minimum change over time, from one size of container or fill size to another Machine height can be adjusted to match with other machines so as to synchronize with each other efficiently Can run dry and wet rubber stoppers and supplied with liquid collecting tray Applications areas: Food and beverage Chemicals Pharmaceuticals Cosmetic applications

Automatic Volumetric Liquid Filling Machine

Get Price Quote

SALIENT FEATURES:- ± 1 % Filling Accuracy On Single Dose. No Bottle No Filling System. Rigid Vibration Free Construction For Trouble Free Performance. S.S. Elegantly Matt Finished Body. Elegant And Easy Control Panel For Total Control On Operation. Minimum Change Overtime, From One Size To Another Container Or Fill Size. Self Lubricating UHMW- PE Guide Profile For SS Slat Chain Provides Low Friction Wear Surface, Smooth And Noiseless Conveying. Error Code Display On AC Frequency Drive On Control Panel. Drain Tray Around Machine Platform. Drip Tray Under The Conveyor. Mechanical Bottle Stopping Arrangement. Synchronized Two Nos. A/C Drives For Main Motor & Conveyor Belt. OPTIONAL FEATURES:- Automatic Chain Washing System For Conveyor Belt. In-built Pre-inspection. Acrylic Cabinet. Acrylic Cover On Conveyor. Float Tank (Holding Tank) With Or Without Stirrer.

Automatic Volumetric Liquid Bottle Filling Machine

Get Price Quote

we are offering automatic volumetric liquid bottle filling machine, filling accuracy on single dose. rigid vibration free construction for trouble free performance. s.s. elegantly matt finished body. elegant and easy control panel for total control on operation. minimum change over time , from one size to another container or fill size. reciprocating filling nozzle with self centring device to avoid foaming. the unit is made compact & versatile -as per gmp norms. no container no filling system-to avoid spillage. synchronised a.c. drives for conveyour & main drive. technical specification model no dalf-100 (4 head) dalf-150 (6 head) outputhour* 2500 to 6000 3500 to 9000 electric motor main machine 1 hp 440 volts 3 phase 50 (four wire) conveyor 0.5 hp 440 volts 3 phase 50 (four wire) container size ø 30 mm to ø 100 mm, maximum height 210 mm fill size 10 ml. to 500 ml. (with the help of required change part) overall dimension 2035mm (l) x 1050mm (w) x 1400mm (h) *note : depending on nature of liquid & fill size.

Automatic Volumetric Bottle Filling Machine

Get Price Quote

Automatic Volumetric Bottle Filling Machine, Automatic Liquid Filling Machine

volumetric liquid filling machines

Get Price Quote

volumetric liquid filling machines, Auger Filler Machines

Four Head Liquid Filling Machine

Get Price Quote

Four Head Liquid Filling Machine, Auger Filling Machine

Automatic Volumetric Liquid Bottle Filling Machine

Get Price Quote

Automatic Volumetric Liquid Bottle Filling Machine, Bottle Labeling Machine

Volumetric Liquid Filling Machine

Get Price Quote

Volumetric Liquid Filling Machine, self adhesive machine, Food Machinery