Automatic Linear Vial Washer

Get Price Quote

Automatic Linear Vial Washer Machine is used for the washing of pharmaceutical glass vials. We are having two different models of vial washer which provided output of 120 vials per minute and 240 vials per minute. These models are most suitable for the online untouched vial filling production line. Salient Features Compact cGMP model. Provides production output up to 250 vials per minute. All contact parts made from high quality stainless steel AISI SS 316L. Machine structure & other parts made from AISI SS 304 SS Tanks & trays made from SS 316L by argon welded with round corner. SS pump made from SS 316L with mechanical seal Monoblock pump. SS filter housing made from SS 316L. All Nozzles made from SS 316L. Special Pocket system ensures easy and trouble free washing of vials from outer and inner side. Indexing motion makes easier for syringes to move inside vial, when it is in stationery motion. No Change parts are required from 5 ml to 30 ml vial. Washing cycles can be adjusted as per customer requirement. User friendly machine, even semi skilled operator can operate the machine very easily. A Special clutch device is incorporated for Stoppage of Machine in the event; vial is over turned or over diameter. Variable A.C. Frequency drive for Main drive and conveyor. Pumps with tank (60 litres each) 2 nos. In feed Wire Woven Belt for feeding of Vials. HDPE material Vial pockets. Machine is totally robust and withstands continues operation for long working hours without any trouble. Machine is equipped with PLC s Vials pushed from in feed tray and then move on wire woven conveyor belt, which align the vial in correct position, to enter in to the carrier pocket with help of oscillating guide rails. Oscillating arm deliver the vial inside pocket in mouth down position over spraying nozzles. Multijet sprayers fixed at the top cause the total external and internal surface to be washed. To avoid any possible cross contamination between two different waters, each washing station is provided with an independent circuit. Carrier pocket is moving with indexing motion. When the baskets have completed their motion the needles are lifted. They penetrate the vials, spraying jets of water or compressed air then return down. The baskets movement then advances by one station. Each station of vials passes through the washing cycles selected. The duly washed vials then delivered to the out feed tray with neck opening upward and then automatically re ordered to sterilizing tunnel with back pressure.

Rods Unifix Anchor Nut Bolt Washer

Get Price Quote

Best Deals from Washer

SS SPRING WASHERS

Get Price Quote

We are supported by an advanced packaging system and work methods that help us in making premium packaging of the lot for ensuring easy handling. Our organization is positioned at Gujarat(India) and has gained immense acknowledgment and a respected place in the market. Spring Washers are made of the finest quality material with a distinct design and high durability.

Stainless Steel Spring Washer

Get Price Quote

1000 Piece (MOQ)

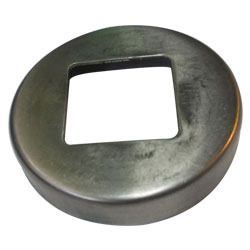

Stainless Steel Square Washer

170 Per Kilogram

500 Kilogram (MOQ)

Stainless Steel Washer

250 Per Kilogram

100 Kilogram (MOQ)

Stainless Steel Square Washers

Get Price Quote

rotary bottle washer

Get Price Quote

The Multipack Rotary Bottle washing Machine is compact and highly efficient machine with elegant look. This multi functional multi featured machine meets the GMP requirements of washing for glass and plastic bottles. The machine operates on the Rotary principle with "GENEVA" mechanism and requires manual loading and unloading of bottles.

Tab Washer

Get Price Quote

Plain Washer, Plain Big OD Washer, Plain Small OD Washer, Spring Lock Washer, Spring Washer Heavy Duty, Tooth Washer, Serrated Star Washer, Tab Washer with One Tab, Tab Washer with Two Tab.

PTFE Washers

5 - 35 Per Piece

10000 Piece (MOQ)

Rubber Flange Washer

9 Per Piece

100 Piece(s) (MOQ)

Copper Washers

Get Price Quote

We are amongst the leading manufacturers of quality Copper Washer which are manufactured using quality copper. As copper is a good conductor of heat and electricity, it is used for piping, electronics, household products and bio medical applications. It is easy to install and is made available in different sizes.

Stainless Steel Washer

152 Per Kilogram

100 Kilogram (MOQ)

Rubber Flat Washer

1 - 20 Per piece

1000 Piece (MOQ)

Steel Washer

40 - 70 Per Kilogram

Washer

Get Price Quote

Plain washer , plain big od washer , plain small od washer , spring lock washer , spring washer heavy duty , tooth washer , serrated star washr , tab washer with one tab . , tab washer with two tab.

rotary bottle washer

Get Price Quote

Geneva Mechanism. Four inner (Included one air wash) & one outer. Sequence of washes to customer's choice. Easy operation. Stationary nozzles eliminate contamination of water cycles. Easy loading and unloading. Individual solenoid valve for each washing sequence that eliminates carbon plate and other accessories reduces leakage and maintenance to minimum. Higher capacity centrifugal pumps to wash bigger bottles (500 & 1000 ml.). (optional) The stationary nozzles avoid chipping of bottle necks.The stationary nozzles avoid chipping of bottle necks. Pumps and tanks are mounted on portable stand for easy maintenance. Bottle guide system especially for lightweight bottle. Separate panel control to avoid any short circuit due to spraying of water. S.S. glycerin filled pressure gauges.

Bottle Washer machine

Get Price Quote

We are supported by a team of well-trained professionals and advance machines that help us to offer Bottle Washer to our customers. These bottle washer are made by our qualitative metals such as bronze, brass, steel, iron and others incorporating sophisticated technology. Our provided bottle washer is highly praised by customers for their high tensile strength, perfect finish, and long shelf life. To fulfill the demands of customers, we provide these bottle washers in various sizes, shapes and dimensions. Features : Long service life High operational fluency User friendly design

Stainless Steel Washers

Get Price Quote

We are offering Stainless Steel Washers. we provide a broad array of stainless steel washers, which procured from reliable manufacturers from all over india. these are manufactured according to the din 125 specifications and are offered by us in a variety of material grades and sizes. variants : plain (punched) washers spring washers square section flat section availability : sizesm2 to m36 material gradesss 304ss 316ss 310ss 321 attributes : available without burrsnon-corrosive high stress bearing resistant to wear and tear perfect gripping action bright finishing required with bolts for : packing gripping.

SS Flat Square Washer

Get Price Quote

valve washers

Get Price Quote

Valve Washers Description : Fluid Tech Hyradulics bring forth quality Check Valves which works as a mechanical device which normally allows oil to flow through it in only one direction. It has dual valves for flow of fluids. It works automatically without manual action. It is designed for specific cracking pressure. It is highly durable and is made available in different sizes.

Foot Valve Washer

Get Price Quote

The Alixe polytech incorporates in manufacturing the high quality Foot valve washers. This are made up using ultimate quality raw stuff and highly advance machinery. These are available in blue colour and size starts from 15 mm up to 80 mm .It is enclosed with the natural rubber washer which provides the batter control to backflow at minimum pressure.

High Pressure Washer

35,000 - 500,000 Per 1 NOS

10 Piece (MOQ)

Heavy Duty High pressure Washer FLOW 8.5 - 15 LPM PRESSURE 0- 200 BAR PUMP HEAD : SS SUITABLE FOR 80 DGR TEMPRATURE

Stainless Steel Washers

Get Price Quote

Plain Washers

Get Price Quote

We manufacture our range of Plain Washers in different size options, dimensions, and finishes to suit different industrial applications. These are in high demands in the competitive market owing to their dimensional accuracy, high tensile strength, abrasion resistance, flawless finish, and durability. Our range of Plain Washer is quality tested on well defined parameters by our team of quality controllers. We also manufacture different types of washers as well i.e Tab Washers, Heavy Duty Washers, Tooth Washers, etc. To satisfy our clients fully, we also provide them with testing certificate. Our plain washers are also available in customized forms and at market competitive price Stainless Steels Material Grade : 304, 304B, 309, 310, 316, 316B, 317, 317L, 321, 347, 401, 416, 430 & 501. Diameter : M6 to M72 Duplex & Super Duplex : UNS31803,S32750. Diameter : M6 to M72 Hastelloy : Hastelloy C-276, Hastelloy C-22. Diameter : M6 to M72 Exotics : 904L, A-286, Alloy20, Alloy50, NitronicAlloys50, Titanium. Diameter : M6 to M72 Nickel Alloys : Inconel600, 601, 625, 718, 750, 800/800H, 825, 925, Monel 400, 405, K-500 & Nickel 200. Diameter : M6 to M72

Washer

Get Price Quote

We are offering washer.

Plain Washer

0 - 1 Per Piece

Dal Washer

Get Price Quote

Moong dal (Green Gram) and Chana dal (Chick Peas or Chick Pea) are very popular in the Chinese, Indian and Pakistan cuisine and are increasingly consumed as deep-fried snacks.Our Dal washing machine are manufactured by fabricate using solid and superior quality of stainless steel 304. We have been efficiently able to offer to our customers this range of Dal Washing Machine. The dal washer machine has been made to process high quality and completely hygienic mung dal, moong dal (Green Gram) and Chana dal (Chick Peas or Chick Pea snacks. Moreover, these machines are fitted with reduction gear box. Complete stainless steel body of these machines is widely appreciated by the clients. Operating Principle of Dal washing machine The spacialized paddles are positioned to move the material in opposing lateral directions as well as radically. The paddle design is generally employed where friable materials are being washed.Dal washer consists of several elements: a centrally mounted horizontal shaft that rotates within a cylindrical container, paddleswashing elements that are attached to the centrally mounted shaft, special openings at the top for feeding materials, manually tilt able tank operated, inside a cylindrical conduit and a complete drive unit. Due to continuous improvements, we reserve the rights to alter and/or amend dimensions/design without prior notice.The figure for capacities given are for guideline only may very force case to case and depending many factors.

Air Washer

Get Price Quote

FRP Washers

Get Price Quote

The basic components of an air washer system are a chamber that contain a series of spray nozzles, an eliminator section that removes water from the air that is exiting the air washer and a sump which catches both the sprayed water droplets and the water that was collected by the eliminators. The spray section will either add moisture to the air or dehumidify the air, while washing solid particles out of the air. The eliminator section in many cases is a "W" or a series of "W"s in shape. This section, forces the air to contact the eliminator components, which in turn knocks down water droplets and air borne solids. The sump is the collection basin for the system. The washed out solids, lint, dust, and water all collect in this area.