Mineral Water Bottling Plant

750,000 Per piece

1 piece (MOQ)

Mineral Water Bottling Plant

Get Price Quote

CHLORINE DOSING SYSTEM Raw water may contain living micro-organisms and organics which are objection a Membrane as it may cause fouling to deteriorate the performance. Even water may contain ferrous which can be oxidized to ferric oxide which is settling down in storage tank. We have offered a Hypo chlorite dosing system for this purpose. About 3-4 ppm of sodium hypo chlorite solution is dosed in raw water storage tank. This reacts with water to form a hypo chlorite acids which acts as disinfecting agent. For this purpose one no. of HDPE hypo chlorite solution preparation tank along with one nos. of dosing pumps are provided. Required suction / discharge pipe work in pvc construction is provided with isolation valves. Dosage rate is adjusted as per the actual requirement, which may very on case to case basis RAW WATER STORAGE TANK One Nos. of Raw water is required in for storage of chlorinated water having appropriate capacity. The tank is fitted with PVC pipe work & isolation valves and suitable type of level indicator. PRESSURE SAND FILTER Raw Water is first filtered by filtration unit in series prior feeding R.O.Plant. Pressure Sand Filter Unit is provided for removal of suspended matters & turbidity from raw water. PSF Unit is a SS vertical Pressure Vessel. Internally, it is fitted with bottom collecting system. Uniform grades silica quartz sand is charged on the supporting media of pebbles and gravels. This unit is fitted with SS frontal pipe work and Multiport Valve externally. During service cycle water is passed in down ward direction through sand bed, thus entrapping suspended matter & turbid particles. Over a period of time, sand bed gets chocked due to suspended matters resulting higher pressure drop and lesser floe. At this stage filter bed need to be backwashed. When pressure drop across the sand bed increases beyond the specified limit (0.5 kg/cm²) or quality of filtered water determinates, whichever is earlier. Regeneration involves backwash & rinsing of Sand Bed as below. For backwashing service water is passed in reverse direction of service cycle to loosen the filtering media bed. Due to this, entrapped suspended matters get free and come out along with effluent water. Backwashing is continued for about 10- 15 minutes or till the effluent coming out is clear For Rinsing of Sand Bed: Service water is passed in down ward direction to settle down the sand bed. The effluent water is drained for about 5 minutes time to ensure all unclear water is drained down. ANTI SCALENT DOSING The hardness salts of calcium & magnesium are likely to be precipitated if concentration exceeds its solubility limit & it may faults the membranes resulting into scaling which ultimately leads to poor treated water quality from R.O. System. To prevent this a anti Scalent dosing (scale inhibitor) dosing system is provided. Normally a scale inhabitator like Perma care 191 or equivalent chemical is dosed in feed water. Dosage rate is 4-5 mg/liter. A HDPE chemical preparation tank with an electronics diaphragm type dosing pump is provided for this.

Best Deals from Water Bottling Plant

Mineral Water Bottling Plant

200,000 - 1,400,000 Per piece

A mineral water bottling plant is a facility where natural mineral water is collected, treated, bottled, and packaged for sale to consumers. The plant must also comply with various regulations and standards to ensure the safety and quality of the water and the packaging.

Drinking Water Bottling Plant

Get Price Quote

We are providing different models in this kind of machines. Machine is suitable for filling 200 ml to 2000 ml water bottle with change parts. With rich industry knowledge, we are highly influential in presenting a premium quality Packaged Drinking Water Bottling Plant to compete with exact requirements of our clients. This bottling plant is used in numerous industries for solving drinking water issues. Due to the easy installation, our Packaged Drinking Water Bottling Plant is well known among our vast range of clients from across the country. Moreover, customers can purchase this plant from us at affordable prices within predefined time frame. Features : Automatic, Semi-Automatic 10 Bottle/min, 20 Bottle/min, 30 Bottle/min, 50 Bottle/min 0-500 ml, 500ml-1 litre, 10 litre- 20 litre Ro Plant Capacity: 500-1000, 1000-5000, 5000-10000, >10000 Jar Filling Capacity (Jars/Hour) 120 Jar per hour Pouch Filling Capacity (Pouch/hour) 2000 Pouch per hour Water Purification System, Bottling Machine, Pouch Packing Machine, Jar Filling Machine

Mineral Filler Unit

Get Price Quote

Kaushik Engineering Works offers a wide range (1.5-50 tons) of filler storage and feeding solutions for the customers to choose form, depending on the site requirements. A variable speed computerized synchronized metering system ensures the right proportioning in the mix.

Mineral Water Bottling Plant

1,100,000 Per Piece

1 Set(s) (MOQ)

Mineral Water Bottling Plant

Get Price Quote

We offer mineral water bottling plant. We are one of the leading mineral water plant manufacturers, exporters and suppliers, providing state of the art mineral water plant. Our plant is highly appreciated for its effective filtration of contaminated water. We ensure our clients that our mineral water plant provides bacteria free water, which is good for health. It ensures to provide water in its purest form without any contamination. Additional machines like blowing, bottling, batch coding machine etc. Are available with us.

Mineral Water Bottling Plant

400,000 Per Piece

1 Piece(s) (MOQ)

Mineral Water Bottling Plant

1,500,000 Per Units

Mineral Water Bottling Plant

1,500,000 Per Unit

water bottling plant

970,000 - 3,000,000 Per Piece

Mineral Water Bottling Plant

Get Price Quote

Mineral Water Bottling Plant

Mineral Water Bottling Plant

Get Price Quote

Mineral Water Bottling Plant, Shrink Wrapping, pre inspection conveyor

Mineral Water Bottling Plant

Get Price Quote

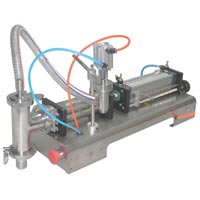

Mineral Water Bottling Plant, Mineral water Bottle filling Capping Machine

Mineral Water Bottling Plant

Get Price Quote

Mineral Water Bottling Plant, Tissue Paper Making Machine

Mineral Water Bottling Plant

Get Price Quote

Mineral Water Bottling Plant, Water Purification Systems