ceramic chutes

500 Per Piece

life comperision f 2 times more than high chrome/ni-hard f 3 times more than cast chrome alloy f 3 times more than cast basalt f 4 times more than abrasion resistance steel f 8 times more than stainless steel f 15 times more than mild steel f 43 times more than polyurethane industrail application sleeve, mechanical seal, plunger, pipe, burner nozzle, ferrule tube, washers, thermocouple sheath, thread guide, pulley, ceramic rod, bearings, valves, impeller, crucibles, bush and many more places where the matter is wear, temperature, erosion, and corrosion. different quality f aluminum oxide – 92% f aluminium oxide – 90% brown f aluminum oxide – 90 – 99.7% f zirconium f zta f mullite f silicon carbide

Wear resistant rubber liner

3,000 - 30,000 Per Piece

10 Ton (MOQ)

BTo Enhance Productivity & Proficiency of Your Manufacturing Process with Machinery Longevity As a prominent Wear Resistant Rubber Liners manufacturer and supplier, Kedar Rubber offers a comprehensive range of molded and extruded rubber products with the utmost quality and standards. Our premium quality Wear-Resistant Rubber Liners are designed to deliver complete protection against abrasion, corrosion, and impact in different industrial applications. Besides, our liners can withstand critical operational conditions to increase the durability of your equipment and lower maintenance costs. We manufacture products under the stringent watch at each production stage, our liners are best applicable in assorted industries. At Kedar Rubber, we accomplished the bespoke needs of our customers from different industries including cement, mining, aggregate, and many more. For such industries, wear-resistant rubber liners are the necessary component that provides consistent, robust, and cost-efficient protection to their expensive machinery and makes their manufacturing processes safe and efficient. Product Overview Material - Based on tailor-made requirements, liners are manufactured using different material compositions like natural or synthetic rubber, or blended compound. Natural rubber comprises unmatched abrasion resistance and is best for general-purpose applications. Besides synthetic rubbers are applicable where it requires increasing the resistance capacity to maximum temperatures, chemicals, or oils. Dimension & Thickness - The dimensions and thickness vary according to the requirement of protection level. For specific size and shape requirements, liners can mold or cut to complex curves, angles, or shapes to fit the dimensions of your machinery perfectly. Custom Edge Design - In addition, custom edge design helps trouble-free installation of liners and enhances equipment performance. Finishing & Texture - The surface textures and finishes of liners depend on the area of applications. For example, a smooth surface is essential for crucial material flow and prevents build-up. A liner with diamond, ribbed, or other patterns helps reduce material sticking, improving grip, and boosting abrasion resistance. Using customized channels or grooves, it eases the material or fluids flow, reduces wear, and improves efficiency. For different applications, it is required to customize wear-resistant liners like chemical, heat, UV & Ozone resistance. Our consulting team discusses your custom requirements based on the material handled, specific environment, and machinery information. For the precise needs of customers, we proffer prototyping services. In such cases, we allow them to test the liner in their work environment prior to proceeding with production. We assure you that, in the final production stage, we manufacture products that best meet your custom specifications and requirements. Uses Wear Resistant Rubber Liners are widely used in various industries for their different applications. Mining and Quarrying industries – Ball Mills, ore mills, coal mills, and more to enhance equipment life and operation efficiency and performance. Chemical industries – Heat exchangers, coolers, reactors, and other equipment to protect them from wear and corrosion. Cement industries – Hoppers, line mill feeders, and more to protect from the harsh nature of cement dust and other raw materials. Aggregate Industries – Helpful for protecting crushers, conveyors, screens, and other equipment from the endless effect of aggregate materials. Power Industries – Improve reliability and performance of thermal power generators and other equipment.

Best Deals from Wear Resistant Liner

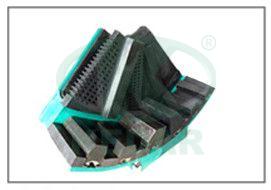

wear resistant ceramic liner

300 Per Piece

RUBBER LID FRAME FOR MANHOLE

5,000 - 25,000 Per Piece

2 Piece (MOQ)

The use of a lid or plug frame is to hold the lid cover during milling operations. A lid or manhole frame with a flanged design supports the lid plug making tight sealing. Moreover, it helps absorb vibrations and protects the mill from wear and corrosion. The robust design and properties of rubber material make it a vital component of the mill for the secure milling process and enhance its lifespan. Its flanged structure makes tight sealing that prevents any leakage of grinding material, dust, or slurry. The plug frame supports bolts or lid plug tightly, thus, preventing leakages even during high pressure and vibrations inside the ball mill. The rubber lid frame makes a dust-tight and airtight seal around the manhole. The flexibility and resilience nature of rubber ensures the plug frame can securely hold the lid plugs. This sealing mechanism is an essential part of safe and trouble-free milling operations.

wear resistant ceramic liner

80 Per Piece

wear resistant liner

350 Per

10 Piece (MOQ)

wear resistant liner

Get Price Quote

1 Metric Ton (MOQ)

wear resistant liner, SILICONE CARBIDE BURNERS, High Alumina Ceramic Ferrule

Wear Resistant Rubber Liners

Get Price Quote

Wear Resistant Rubber Liners, Mooring bollards, Pneumatic Fenders