Spot Welding Controllers

Get Price Quote

1 Piece(s) (MOQ)

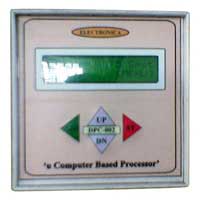

We are offering spot welding controllers. For the best quality spot welding controllers, “s. S. Controls” is the perfect destination for you. The micro controller based spot welding controllers made accessible by us are find their application in different kinds of welding machines like table mounted microspot welders and manually operated (rocker arm type or similar) spot welding machine. They are known for their low maintenance cost. The precise time and energy control of these controllers ensures consistent weld quality. Besides, we are one of the eminent spot welding machine controller manufacturers in india.

Projection Welding Controller

Get Price Quote

1 Piece (MOQ)

It consist of two digit digital spot welding timer with output of 220 volt with 2 solenoid valve & including control of current by SCR’s. It consist the store parameter upto12 jobs. We provide display with LCD based.

Best Deals from Welding Controller

Spot Weld Controller

5,500 - 7,500 Per Piece

We feel immensely pleased to offer our customer world class collection of Spot Weld Controller that are available with longer warranty.Features:DurableReliableCorrosion ResistanceLong Service LifeLess maintenancePortableEnergy efficient

welding controller

Get Price Quote

PRESS TYPE SPOT WELDER ROCKER ARM TYPE SPOT WELDER TABLE TYPE SPOT WELDING MACHINE PRESS TYPE PROJECTION WELDER CAPACITOR DISCHARGE STORED ENERGY PROJECTION WELDERConstant Current Control with Secondary feedback. Large Display for Secondary Current Primary Voltage. 32 Welding Schedules can be stored for reference. 3 steps welding current (Pre-heating, Welding Current, Temper Current). Up Slope and Down Slope Current feature to avoid weld splash. 2 Pressure Valve Outputs. In Built Weld Counter. Self Error Diagnosis and Display.

welding controller

Get Price Quote

We are among the leading Welder Controller Manufacturers in India. We manufacture superior quality Welding Controller that is used in different industries. These are very efficient to work at any range of voltages. They are featured with soft start and smooth handling. The Resistance Welding Controller of our company is unrivaled in the market due to its high performance and durability. These have all the features to meet the international standard of quality. They consume very less electricity as compared to the other welding controller. In spite of a very high standard of quality, we have kept the price of our products within control. Specification of Resistance Welding Controller Using Micro Computer Mode Available : Spot (Single & Repeat), Seam, ProjectionMaximum 1000A SCR (Back to Back) can be triggered using this type of controller.Control using pulse transformer (Multiple Pulse Firing Technique to Reduce the Gate Loss of High Power SCR.)Close loop PI control (Optional) available on demand.Open loop % current control inbuilt.Solenoid valve output 24V @2A (max).Motor enable 24V@1A (For Seam Welding).Thermostats function for detection of overheating and switch off the m/c.Pressure switch & water switch input optional. Parameter of The Controller Pre-Sqz Time : 0 to 99 CycleSqz Time : 0 to 99 Cycle Weld Time Pre Heat : 0 to 99 CycleMain Heat : 0 to 99 CyclePost Heat : 0 to 99 Cycle1st Cool : 0 to 99 Cycle2nd Cool : 0 to 99 Cycle3rd Cool : 0 to 99 CycleHold Time : 0 to 99 CycleOff Time : 0 to 99 Cycle Current Pre Heat Current : 10% to 99%Main Heat Current : 10% to 99%Post Heat Current : 10% to 99%Input of The Controller : 230-500v AcInbuilt 24V dc power supply for solenoid valve or other device power supply.

welding controller

400,000 Per Piece

welding controller

Get Price Quote

welding controller

Get Price Quote

Digital Spot Weld Controller

6,800 Per Piece

welding controller

Get Price Quote

the very latest technology in resistance weld monitoring; it provides precision real-time dynamic measurement of all the welding variables. A special version was made available for the AWS3 and has a variety of functionalities which are described in the Technical Data Sheet of AWS3. The following description as well as the Technical Data Sheet which can be downloaded in "More Information" apply to the MG3 product. With increased emphasis on accountability, the MG3 Digital Weld Monitor offers the tools required for process development, production monitoring, data collection, and analysis to support your ISO, GMP and TQM requirements.

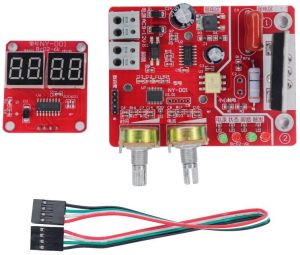

100a spot welding machine diy controller panel

Get Price Quote

Specification Opto isolation of power and control circuits Adjust the response time with a simple potentiometer Maximum Triac current 100A The digital control interface displays the current time and current settings. Power board 9-12v (AC) Size: 55 x 75 mm / 33 x 35 mm

stud welding controller

Get Price Quote

Under the supervision of experts, We Sparkweld Engineering, Mumbai, are busy in manufacturing and providing best quality product range of Stud Welding Controller to our valuable clients. Stud Welding Controller is a fast method for welding studs of different shapes and high thickness materials to provide strong fixation of studs on a permanent basis. Our products are high in performance, easy to use, require minimum maintenance, and highly resistant to stain and are supplied across the world at the attractive price range. For stud welding process, Stud Welding Controller is coupled with manual metal arc (MMA) and welding rectifier. After welding, the stud does not break even if it is bent to any direction. Characteristics: All important functions are indicated and controlled by LCD. Simple handling. Excellent welding and high power on time. Highest operational reliability. Robust, powder coated metal housing. Electromagnetic compatibility tested. Optimal safety during welding through integrated safety switches. Quick welding sequences through short charging time. Automatic module to control automatic stud feeding system, ideally suitable for difficult welding tasks. Charging voltage not affected by supply voltage variations. To prevent overheating, an internal charging time regulation system is adopted. To prevent burnt contacts 50mm2 welding cable socket is used. For capacitor discharge stud welding process, High-performance stud welding unit is used. Stable fixing of welding cable socket is provided to prevent any damage. Specifications: Model: Execute Drawn Arc Stud Welding controller. Welding Range: M-6 to M-12, up to 100 mm long studs. Welding Material: S.S., Low Carbon Steel. Welding Time: 0-1400m/sec. Welding Rate: Up to 25 pieces per minute. Standard Gun: DAP-16. External Power Supply:80v D.C. Constant Current Type MMA Welding Rectifier. Dimensions (LxWxH):460x290x545. Weight:25Kg

welding controller

Get Price Quote

welding controller

Get Price Quote

MECHELONIC ENGINEERS’ expertise in the field of Resistance Welding technology has been distilled into a versatile Microprocessor based control to serve the needs of vast majority of users of Resistance Welding Machines. 16-digit alphanumeric display to furnish tutorial style guidance to the user. Response, by YesNo and 0 to 9 keys only, is needed for schedule generation. Same microprocessor unit with embedded mater software meets the requirements of spotprojection welding, robotised fixture linkups as well as seamrol-spot welding.

welding controller

65,000 Per Piece

1 Piece (MOQ)

spot welding controller

21,000 Per Piece

1 Piece (MOQ)

Resistance Welding Controllers

Get Price Quote

MAIN FEATURES TECNA Weldcon brings you the latest and most sophisticated Welding Controller Units built by TECNA. TECNA has a range of Welding Controller Units that are designed and built keeping various application areas in mind. All control Units are invariably Microprocessor Controlled and manufactured using the latest technology in electronics. Compliance with RoHS is ensured during the production stage and Silicone Based Compounds are totally eliminated in contents to ensure compliance with Sheet Metal Workshop Manufacturing Requirements. To ensure modularity and scalability, each control unit is designed to have some basic built - in functions, that can be extended by addition of optional accessories, which enhance and add new functions and capability to the control unit. Firmware of control units is very easily upgradable. This ensures that customer works with the latest software that is possible. Control Units are easily integrated on to the existing machines for improved performance and additional functionality. They can also be supplied in Kit Form for System Integrators manufacturing automated welding machines. A full fledged welding controller cabinet, complete with SCR and required add - ons can also be built and supplied, for Ready to Install situations. Base Control Units Control Unit Description TE90 Microprocessor based Welding Controller Unit, with Simple SCR Firing Angle Control, for Manual and Pneumatically Operated Machines With Current Compensation Function TE91 Microprocessor based Welding Controller Unit, with Simple SCR Firing Angle Control Specially Built for Multi Spot Welding Head Machines, having Cascade and Concurrent Function. With Current Compensation Function. TE101 A Simple Microprocessor based Welding Controller Unit, with Simple SCR Firing Angle Control With Built - in Ammeter for display of actual measured Welding Current. TE550 A Full Fledged Micro - processor Based Welding Control Unit with Constant Current and Direct Secondary Feedback Function.Extensible by multiple add - ons like, Networking, Robot Handshaking Protocols, Constant Energy Function, Proportional Valve Etc. TE800 A Full Fledged Micro - processor Based Welding Control Unit with Constant Current and Direct Secondary Feedback FunctionSpecially meant for Networked Operation using PLC.

Weld Controller

Get Price Quote

Specifications Controller for welding automation Process Controllers Programmable Logic Control (PLC) based to control Power Source, Positioner, Oscillator & Powder feeder, Water Recirculator Cum Chiller Housed in a seperate Control Panel. Enables fully automatic operation with single button start. Automation Facility : Selectable rotation :0-360O Selectable over-lap of weld : 0-25O Selectable auto boom stepover : 0-100mm. Choice of welding cycle programmes : 10. Choice of interfacing of X-Y (rotation and linear travel) or X-Y-Z (rotation, linear & traverse travel) in fully automatic mode.

resistance welding controller

35,000 Per Piece

spot welding controller

Get Price Quote

16X2 Line LCD Display. I/p : 2 (1 For M/cs Start & 2nd for Reverse direction.) Length & Roller dia programable. Operating Voltage: 24VDC. Dimension : 96 X 96 X 120mm D. Cut-out: 92 X 92 mm.

welding controller

Get Price Quote

Welding controller CPU carries out the Feedback control during welding. It ensures the stable welding current even the fluctuation of power supply there. Guaranteed the welding quality. Count the welding spots. Detect the actual voltage of the power supply. Detect the actual welding current (CC mode).Automatic self-diagnosis, display Error number for any abnormal condition. Two type of current feedback: Welding transformer primary side and secondary side.

welding controller

Get Price Quote

Smart Weld Monitor gives signal instantly if the welded spot is not OK. Welding controller supplies stable welding current by secondary feed-back constant current method. Resistance welding controller has spot welding, 2-head spot welding and seam welding compatibility. Networking of up to 32 machines (optional). Parts of different thickness can be welded in the same welding sequence by setting multiple weld schedules. 15 such programs can be set in this welding controller. External schedule select. Controller has self-adjustment for maximum current. Large LED display gives instant view of the program Controller has 3 easy-to-operate counters to aid in systematic quality control and tip dressing schedules. Up and down slopes. Resistance welding controller can be retrofitted to your existing machines.

Thyristor Spot Welding Controller

Get Price Quote

1 Set(s) (MOQ)

in conventional spot welding when contactors are used there is no way to cycle-by cycle control of current delivered due to mechanical restriction of the contactor. profiling the current deliverd cycle-by-cycle helps in getting a spatter free welding,with minimal to no tarnish plus savings on energy we are looking for oem's requiring assembled controllers / pcb's

ac welding controller

Get Price Quote

ac welding controller, Diode Rectifier (MRT - 200), welding embedded plates

spot welding controller

Get Price Quote

spot welding controller, wire mesh welding machine, spot welding fixtures

welding controller

Get Price Quote

welding controller, measuring equipment, CONTROL TRANSFORMERS

welding controller

Get Price Quote

welding controller, Safety Helmet, Safety Jackets, Safety Products

welding controller

Get Price Quote

welding controller, weld controllers, spot welding controller

resistance welding machine controller

Get Price Quote

resistance welding machine controller, electronic measuring instruments

welding controllers

Get Price Quote

welding controllers, under water led lighting