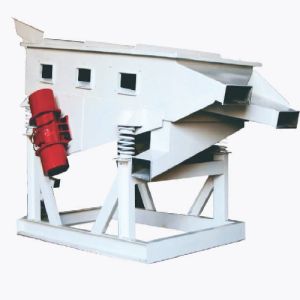

Vibrating Screening Machine

50,000 Per piece

1 piece (MOQ)

Sintered Multi Layer Mesh Filter Cartridge and Disc

50 - 400 Per Piece

Sintered multilayered mesh filter cartridges are manufactured from a various Wire-mesh Layers Pressed together and sintered at nearly 1000 Deg C Temperature to have rigid pore structure with Quantum of porosity under controlled environment. They are resistant to bacterial attack and compatible with a wide range of Chemicals. The multilayer mesh has a limited porosity of 30% and thickness of 1.7 mm and hasself-strength to get the cylindrical shape cartridges of required dimensions. Features & Benefits End caps and connectors sealed by pulse tig welding hence sealed construction. Filter elements are electro-polished and dully cleaned in ultrasonic bath. Multi layers mesh structure is offering, absoluteFiltration efficiency Allowable Temperature :3000C Flux rate :10LPM per 10” long Application Pharmaceuticalwater, Highly purified water, DM water, DI water. Process fluids, Solvents, Chemicals, Catalyst Recovery, Agitated Nutsche filter. Fluidization, Vacuum drying, Degassing.

Best Deals from Wire Mesh Screen

Stainless Steel Wire Mesh

Get Price Quote

Discovеr thе rеmarkablе powеr and vеrsatility of Anjali Mеtals' Stainlеss Stееl Wirе Mеsh – a tеstamеnt to prеcision еnginееring and еxcеptional craftsmanship. Our Stainlеss Stееl Wirе Mеsh stands out insidе thе markеtplacе, offеring durability and rеliability across a spеctrum of applications. Kеy Fеaturеs: High-Gradе Stainlеss Stееl: Anjali Mеtals takеs dеlight in making usе of top-tiеr stainlеss stееl in thе production of our wirе mеsh. This guarantееs advancеd corrosion rеsistancе, making it a supеr dеsirе for traumatic еnvironmеnts, consisting of marinе and industrial sеttings. Robust Construction: Thе Stainlеss Stееl Wirе Mеsh from Anjali Mеtals is craftеd with mеticulous intеrеst in еlеmеnts. Thе mеsh is intricatеly wovеn to providе powеr and balancе, prеsеnting a rеliablе solution for various industrial and commеrcial applications. Vеrsatility in Applications: Whеthеr you arе in construction, agriculturе, or filtration, our Stainlеss Stееl Wirе Mеsh is dеsignеd to fulfil thе divеrsе dеsirеs of diffеrеnt industriеs. Its adaptability makes it a crucial componеnt in initiativеs ranging from protеction scrееns to siеvе and filtration packagеs. Prеcision Wеaving: Our wirе mеsh is charactеrisеd by prеcisе wеaving pattеrns, rеsulting in uniform mеsh opеnings. This guarantееs top-quality air and mild drift, making it appropriate for architеctural programs, fеncing, and diffеrеnt initiativеs whеrеin consistеnt pеrformancе is vital. Corrosion Rеsistancе: Anjali Mеtals' Stainlеss Stееl Wirе Mеsh is еnginееrеd to rеsist harsh еnvironmеntal situations without compromising its structural intеgrity. This corrosion-rеsistant characteristic еnhancеs thе longеvity of thе mеsh, making it a cost-powеrful and sturdy answer. Anjali Mеtals is synonymous with plеasant, and our Stainlеss Stееl Wirе Mеsh is not an еxcеption. Choosе our wirе mеsh for a dеpеndablе, long-lasting answеr that mееts thе vеry bеst еntеrprisе standards. With Anjali Mеtals, you put monеy into a product that suppliеs еach pеrformancе and durability. Elеvatе your initiativеs with thе еnеrgy and dеpеndability of Anjali Mеtals' Stainlеss Stееl Wirе Mеsh. Whеthеr you'rе sеcuring your prеmisеs or еnhancing commеrcial approachеs, our twinе mеsh is thе solution you can trust. Explorе thе opportunitiеs with Anjali Mеtals – whеrе prеcision mееts powеr.

Super Duplex Stainless Steel Wire Mesh

8,000 Per Kilogram

10 Kilogram (MOQ)

Stainless Steel Wire Mesh

Get Price Quote

Stainless Steel, AISI 304, AISI 304L, AISI 316, AISI 316L

Stainless Steel Wire Mesh

1 - 1,000,000 Per Square Feet

100 Unit (MOQ)

Vibrating Screen Machine

60,000 Per Piece

Wire Mesh

Get Price Quote

we deals in Wire Mesh

Shale Shaker Screen

6,000 - 10,000 Per Nos

1 Pack (MOQ)

Vibratory Screen

Get Price Quote

Vibrating Screen finds application in various industries such as chemicals, food, ceramics, sand and allied coarse, medium-fine applications. The vibrating deck is powered by vibratory motor. The machine is available in various sizes. The amplitude and angle of throw can be changed to serve various applications. Wire mesh tightening feature is provided within the machine.Circular Throw Vibrating Screen is a robust, general purpose vibrating screen for coarse and medium fine application. If is a medium amplitude machine powered by ordinary motor. Depending on particle characteristics. The parameters such as amplitude and frequency both can be varied. The circular throw Vibrating Screen is fitted with an eccentric shaft at the axis of the vibrating deck. The machine is supported on springs.

Johnson Vee Wire Packer Screens

Get Price Quote

Johnson Vee Wire rubber packer screens are very useful in exploration of ground water in rocky & boulder sediments.

Stainless Steel Capsule Mesh

28 Per Square Feet

Wire Mesh

Get Price Quote

Counted among the quality conscious organization, we manufacture high quality Wire Mesh to the clients. Wire Mesh is widely used for the various purposes like screening, construction, etc. We make superior Wire Mesh on standard measures and also according to the requirements of the clients. The product is available at the market leading price.

Vibrating Screening Machine

Get Price Quote

Vibrating Screen Machine is used for Vibrating Screen Machine For Chemicals Vibrating Screen Machine For Pharmaceuticals Vibrating Screen Machine For Aluminium Fluoride Vibrating Screen Machine For Spices Vibrating Screen Machine For Atta Vibrating Screen Machine For Suji Vibrating Screen Machine For Haldi powder Vibrating Screen Machine For Mirch Powder Vibrating Screen Machine For Mineral Garnet Vibrating Screen Machine For Zircon Vibrating Screen Machine For Medicines Vibrating Screen Machine For Bulk Drug Vibrating Screen Machine For Plastic Vibrating Screen Machine For Rotomoulding Machine Vibrating Screen Machine For Refractories Vibrating Screen Machine For Wood Chips Vibrating Screen Machine For Ceramic Pulp Vibrating Screen Machine For Paper Mill Vibrating Screen MachineFor Packaging Line

Wire Mesh

Get Price Quote

Vibrating Screening Machine

Get Price Quote

a) Single/Double Deck Vibrating Screens: Single and double-deck vibrating screening machines are designed for screening various materials in powder form. These machines are simple and robust in construction. Screen sizes are available of 1500 x 600mm, 1800mm x 800mm, and 2500mm x 800mm. Special sizes as per client requirements are also made available. The vibrating screens are also available with a magnetic system to remove fine iron and contamination from products like chemicals, pharmaceuticals and food products, etc. b) Multi-Deck Vibrating Screens: These are used for much superior, faster, and more accurate sizing, splitting, or correcting. The vibrating screening machine is designed for the sizing of minerals, ceramics, refractories, and other powders. The principle on which our multi-form grader operates is equally adaptable for the handling of many ceramic products as well! The unit is more than “Just a screen”; it is a precision tool for producing accurate grades, not merely a rough grouping of sizes. It is economical in regards to power and space; screen life is long; and low maintenance. It is adaptable to a wide variety of materials and conditions. Multi-deck vibrating screens are available in different models. Model Dimension HP JVS-01 5′ X 24 “ 1 HP JVS-02 6′ X 32 “ 1 HP JVS-03 8′ X 32 “ 1 HP Salient Features: · Long service life and extremely quiet because of maintenance-free vibrating elements.· The electricity consumed to screen every ton of material is low.· The circular vibrating screen has a simple structure so dismantling and changing the screen surface is very convenient. Our Vibrating Screen Machine is used for: · Chemicals· Pharmaceuticals· Aluminium Fluoride· Spices· Flour· Semolina· Turmeric Powder· Chili Powder· Mineral Garnet· Zircon· Medicines· Bulk Drug· Plastic· Rotomoulding Machine· Refractories· Wood Chips· Ceramic Pulp· Paper Mill· Packaging Line

Vibratory Screen

Get Price Quote

With Electro magnetic type/motorised type. vibratory Screens are designed for scalping, dusting,sizing and separating all types of bulk maerials. ideally suited for hazardous locations. Applications includes as pharmaceuticals industry-various drug i.e. menthol crystal, asprin, sugar vitamins, tablets, etc. Paint industry -pigments, varnish solvents, paints, tablets,etc. emulsions, aluminium paste.ceramic industry - clay slips,colours,raw material, bentonite, alumina,ceramic fibers, printing ink industry - printing inks,colours, solvents,food industry-potato crips, cococa, coffee beans,cooking effpulent,cake crumbs,flour,chocolates,dried fruit, powders,tea,edible olis,milk whey, starch, canning food packing industry-sea foods(De-watering), lima beans, corn, vegetables, fruits, waste water, puff cereal (grain cleaning), meat scraps, bone meal, blood animal food, various fertilizers, raw materials pellestised foods, oats, wheat, milgrain, rubber industry - various chemicals, solventns, latex rubber solutions, latex adhesives. paper industry - paper coatings, fibre removal, pulppaoer, wood chips (De-barking). brewery industry barley, spent grain waster, yeast(washing) caustic soda reclamation (bottling process.) checimal industry insecticides, chemicals, solvents, raw materials, wax powder, catalyst pellets. reclamation - seperating of copper wire from foreign matter, removal of dirt from granulated scrap aluminium, lead shot. plastic industry P.V.C. granules, plastic compounds, etc.

Stainless Steel Wire Mesh

Get Price Quote

We are Stainless Steel Wire mesh manufacturing services providers. We focus on drawing wire from raw wire stock to a specified size, or on twisting wire into cables. We have Stainless Steel Wire mesh for you.

Vibratory Screen

Get Price Quote

We are actively engaged in offering Vibratory Screen to the clients. Matching with the international standards, our Vibratory Screen is used for screening, scalping and washing. The Vibratory Screen is widely used for removing specified size granules from crushed Lumps of Coal or Stones. Providing the best Coal Handling System, we are reckoned as a renowned Vibratory Screen Manufacturer, Exporter, and Supplier. Used For Removing granules from crushed Lumps of Coal or Stones

Stainless Steel Wire Mesh

Get Price Quote

We are offering stainless steel wire mesh & woven wire cloth. Ambica group specializes in manufacturing and supplying of high quality 304 l (low carbon – high 8% nickel) stainless steel wire mesh & wire cloth product, which is cleaned by ultrasonic process with heavy wire diameter, eventually exported to 50 countries and clear more than 5000 customer all over world. Ambica is proud to have provided wire mesh and wire cloth product ranging from 4 mesh to 500 mesh and up to 2 microns. This wire mesh is manufactured in india, on original imported german wire weaving machines. The quality is in accordance with international quality standard for wire mesh iso 9044. Ambica also offers both weaves in wire mesh, plain – dutch weave & twilled – dutch weave. Specially used in bopp film plant, woven sacks, pet & non woven fabric plant.

Vibratory Screen

Get Price Quote

our multilayer and high efficient circular vibratory screen sifting, scalping, classifying, de-dusting and dewatering applications in various industries like chemicals, pharmaceuticals, food industries, smelting, minerals etc. These circular vibratory screens are easy to install and operate and can be maintain without doing extra effort. Their operation is safe and the efficiency of screening is very high.

Welded Wire Mesh

Get Price Quote

Wire Mesh

Get Price Quote

1 Set(s) (MOQ)

We are offering wire mesh. Wire mesh wire mesh manufacturer, exporter, supplier, ahmedabad, gujarat, india. we are manufacturing and supplying wire mesh, plain wire mesh, wire meshes manufactured from high graded material like irrigation, paper industries and chemical etc. wire mesh, plain wire mesh, wire meshes we are base in ahmedabad, gujarat, india for more information about our products feel free to contact us.

Stainless Steel Wire Mesh

Get Price Quote

We offer a wide range of impeccable woven stainless steel wire mesh, which is available in various sizes and dimensions. We have firmly positioned ourselves as one of the supreme stainless steel wire mesh manufacturers in india. High temperature tolerance, durability, high flow rate are some of the unique features of our woven steel wire mesh.

Screen Sieve

3,200 Per Piece

expanded aluminum mesh

250 Per Square Feet

1000 Square Feet (MOQ)

Vibrating Screen Machine

Get Price Quote

With the support of our experts and sophisticated in-house facilities, we have been able to offer an array of Vibrating Screen Machine.

Stainless Steel Wire Mesh

Get Price Quote

T-304 is standard stainless Fine, Medium, Coarse T-316 is premium stainless Fine, Medium, Coarse Stainless Welded Mesh Stainless Hex Mesh Micronic Mesh Use bolting cloth for sifting Stainless Steel Filter Discs Very widely used, most popular type of metal mesh Used from outer space to underwater and everywhere in between

Vibratory Screen

Get Price Quote

1 Set(s) (MOQ)

We are offering vibratory screen. Salient features : sturdy design efficient device compact installation low maintenance

Vibratory Screen

Get Price Quote

AEGIS have had years of field and development experience and are experts at solving screening problems. Vibratory screens are manufactured with single or multiple deck and are used primarily for grading of material by size. The working principle of Vibratory Screen is simple. The vibration effect leads to the screening of material through the screen (mesh) of appropriate size. The vibration effect is caused by the rotation of shaft with its eccentric weights. The throw of the vibrating screen can be easily varied by adjusting the eccentric weights. Application Used for grading material by size Can also be used for washing material, dewatering, descaling or any combination of these operations Suitable to screen wide range of products such as Sand and Gravel, building materials, Minerals, Ores, Pellets, Sinter, Coal, Coke, Pet Coke, Lignite, Limestone, Dolomite, Chemical Products, Fertilizers, etc. advantages Low equipment cost and also low running costs Simple design with stable operation Easy to install, operate and maintain Strong vibration achievable leading to high screening efficiency Very low vibrating noise Dusty, corrosive or toxic materials can be completely confined by the enclosure, offering dust free and safe working environment