Welding Machine

It is most probably chosen for high speed and flexibility in maintaining long arc time. The features reduce the frequency of changing electrode rods. When it comes to applications, it is found out to be one of the best apparatuses that can be applied to carry out rational welding over work materials which are usually difficult to handle through conventional types of equipments. In addition to that, MIG/MAG/CO2 Welding Machine can be used for operating over different positions over the work piece. Some of the suitable metals which can be used as work material in this device are aluminum, mild and stainless steel, copper and copper alloys, nickel, magnesium, etc. GENERAL:- The above Equipment Consists of Constant Potential Power Source Wire Feeder Pressure Regulator withFlow Meter and Guage Gas Colled Torch Gas Preheater Gas Hose with Connectors Welding Cable Control Plug DESIGN:- Having Latest Technology Circuit Modular Compact, Suitable for Cirtical Welding Applications, Sturdy Construction for any type of job using Copper coated wire for smooth and Spatter free welding Continuously / Intermittently. PROCESS:- It is universally know as metal Inner Gas (MIG) / Metal Active Gas ( MAG), Welding Process using Argon Gas or CO2 Gas for shielding the weld pool to avoid oxide formation during welding. In this wires of O.8, 1.2 or 1.6mm is continously / Intermittently fed through wire feeder Mechanism Torch to weld different types of Jobs with the help of D.C. Power source. It is a sort of Semi-Automatic Welding Process. APPLICATIONS:- MIG / MAG / C02 Welding Machines are widely used in small as well as large Industries doing Fabrication Work, right From General Repair Work, Grill Making to Heavy Machine Building, Body Building, Vessel Building and Heavy Structural Work, using Copper Coated Wires.

...more

VMC Machine

The CNC milling machine & VMC machine are available at Yash Machine Tools in various models with varying capacities. Machine’s auto execution is quite vibration free and noise free for smooth handling and multi-tasking features.Milling or grinding operation requires precise machining and the inception of CNC embedded milling equipments have brought excellent changes in machining operation, fast, precise and durable production. Yash Machine Tools supplies CNC milling equipments which shows improved and long term performance. Our range of milling equipments are made of high quality and tested materials therefore they are suitable for industries that have greater production requisite. We provide the following types of CMC and VMC Milling equipments.

...more

Vertical Turning Lathe

Yash Machine Tools provide WM series vertical turning lathe, an exclusive workshop device used for tough turning applications on metal sheets. These are made from higher grade components to support long term applications and higher level of productivity. This is a versatile model that is comparatively quick in machining function when compared to other lathe machines. Main Features:- Rough and finish machining Hydro-static guideway, heavy load capacity High precision, low noise High wear- resistance DRO available as optional Suitable for turning intricate metal work materials. Rapid speed in turning. Precise turning of even complicated metal sheets. Saves more time in turning than other types of workshop tools applied for turning. Suitable for milling operations also. Rigid in structure and works for long run. Suitable for heavy turning operations. Special Mechanical Features Rough, rigid and finish machining parts which support for long term applicability. Featured with hydrostatic guide way for heavy load capacity. It provides precise machining with low noise. High wear resistant. Available with optional DRO. Product Code WM 07/VT 100 : Model number C5110 is featured with 1000mm of maximum cutting diameter for V.T.P. and for sideway tool post. The table diameter is 900mm and the maximum work height is 800mm. It can be used for machining up to 2 ton load of work material. The table speed range in 16 steps is 8-250 rotations per minute. The feed range for both the tool posts is 0.9-103. This machine can run with 22KW of main motor power. Product Code WM 07/VT 125 : Model number CD5112 is featured with 1250mm of maximum cutting diameter for V.T.P. and 1100mm of maximum cutting diameter for sideway tool post. The table diameter is slightly larger than the above model which is about 1000mm. It can be fed with maximum of 3.2 ton work load. The table speed range in 16 steps is 6.3 to 200 rotations per minute. Product Code WM 07/VT 160 : Model number CD5116 is featured with 1600mm maximum cutting diameter for V.T.P. and maximum 1400mm cutting diameter for sideway tool post. The maximum work height possible with this model is 1000mm and the maximum work load is 5 ton. The table speed range is 5-160 rotations per minute. The feed range for both tool posts is 0.8 to 86. Product Code WM 07/VT 200 : Model number CD5120 is designed with 2000mm of maximum cutting diameter for V.T.P. and 1800mm of maximum cutting diameter for sideway tool post. The maximum work height is 1250mm and it can be applied for machining up to 8 ton of work load. The table speed range is 4-125 rotations per minute and the feed range for both tool posts is 0.8-86. It requires 30KW of main motor power. Our vertical turning lathe machines are designed to ensure precise turning which remain difficult in conventional lathe machines. We have provided technically best features for consumers to make use of its maximum performance.

...more

Vertical Machining Center

Yash Machine Tools presents WM series vertical machining center/CNC Milling equipment, DMTG vertical machining center a unique machining device designed for milling with tight-tolerance. It is one of the high-precision milling machines provided with vertically orienting spindle. It supports for milling towards accurate and stable machining way and to accommodate complete work materials like ceramics. We provide 6 models of WM series vertical machining centre with CNC milling feature. These models are featured with different dimensions of specifications to accommodate wide range of workpiece. Each model is designed with different table load capacity to accept corresponding weight of work material so that the precision in machining remains undisturbed. Machine Qualities:- XD series machine is a new generation of imported vertical CNC milling machine. This machine, adopted for small and medium production, such as, small plates, disc. Shell parts and precision parts. It has LCD for macroinstruction edit, wich makes the machine easy to operate and liner interpolation and circular interpolation can be realized. This CNC milling machine is ideally suited for accurate milling, boring, drilling, counter boring and tapping operations etc. Automatically on the worktable within one set up. Main Features:- Highly rigid and stable machine structure Highly Speed, High Precision Spindle Highly precision Slideways on all Three Axis Multi-Functional CNC Control System Specifications of WM Series Vertical Machining Center Yash Machine Tools is a well-known machine supplier in India and we have the most sought for workshop machines in different models. Our vertical machining centre/CNC milling device has been designed with attractive features to carry on with accurate machining, speedy performance and support continuous production needs in different industries. Every aspect of specification bears a reason for its presence. Some of the important specifications are given below. Easy to set up on the worktable. Fully automated machine. Suits best for variety of machining applications apart from milling, such as boring, counter boarding, drilling as well as tapping. Featured with LCD monitor that helps the operator to easily grasp the instruction and machine operating procedure. Suitable for machining small, light weight components to medium duty products. Provided with precise spindle which caters to reliable performance. Takes minimum downtime Easy to control and operation features which allows even less experienced operators to easily learn the applications. Made from solid cast iron which helps to withstand several production jobs even if it stays for long hours. Made from corrosion free materials. Can be applied for moderate duty cutting application. Machine weight differs according to the milling capability embedded in each model and machine weight ranges from 2000kg to 14500kgs. We provide exclusive set of gadgets for WM series vertical machining center machine models to experience sustained machining and the standard accessories includes half guarding, air blowing system for spindle, foundation bolt and heel block and coolant system. Optional accessories enhance the performance of equipments. At Yash Machine Tools we supply the following optional accessories for vertical milling center/CNC milling machine such as the full guarding instead of standard half guarding, electric cabinet constant temperature control device (to constantly control or stabilize the frequency of temperature of the device at the time of machining), and with maximum spindle speed capacity of about 10000 rotations per minute. Our service does not stop with supplying machines and accessories as we move a step ahead in terms of offering best customer support and providing spares for the already existing equipments. Consumers who are investing in workshop machines do not have to search for another supplier for buying spare parts as Yash Machine Tools is the right location to find workshop machines and machine related gadgets.

...more

Vertical Knee Type Milling Machine

Yash Machine Tools, a supreme workshop machine supplier in India offers vertical knee type milling machine. It is capable of grinding multiple sides of the work material and stays compatible for other operations like boring and cutting. This kind of mill is comparatively little expensive but when it comes to machining performance; vertical mills prove to be the best than others. We have four different models with specifications that shows variations in milling operations and they are designed with vertical spindle through which excellent precision is guaranteed. The equipments are applicable for machining steel and similar hard metals. Advantages Accuracy in milling Strong guideways support for grinding hard materials It is compact in design Suitable to mill flat, inclined surfaces and slots as well Perfect machining tool to handle important work materials It can be chosen either with vertical mill head or dividing head in accordance with the grinding direction required. It is provided with coolant system that supports for tool safety and durability Model No-X5032/X5032A : This model contains machining table of size 1320X320mm. It is equipped with 3 nos of T-slot which helps for precise and versatile grinding operation. This model can hold up to 500 kg of load. The table can be moved longitudinally up to 700/680mm and in cross direction of up to 255/240mm. The spindle speed is 30-1500 rotations per minute and the spindle step is 18 rotations per minute. The quill travel distance is 70mm and it can work with 7.5kw main motor power. For X/Y and Z axis feed this model runs with 1.5 kw motor power. Apart from that additional coolant motor with 0.125kw power is required. Model No-X5040 : It comes with 1600X400mm of work table and 3 nos of T-slot. The maximum load capacity of this model is 800kg. The longitudinal travel distance is 900/880mm and cross travel distance is 315/300mm. Quill travel distance is 85mm and range of spindle speed is 30-1500 rotations per minute. Model No-X5050 : This model is designed with 2000X500mm of table size and it is provided with 5nos of T-slots. The centre distance is 80mm and the load bearing capacity is 1500kg which is obviously higher than the previous models. The longitudinal travel distance of the table is 1530/1520mm and cross travel distance is 360/345mm. The spindle speed range if 45-1800 rotations per minute and the spindle can make 17 rotations per minute of spindle step. Model No-X6150 : It can bear load up to 1500 kg and comes with table size similar to that of X5050 model. It is provisioned with 5 nos of T-Slots. The table travel distance towards longitudinal direction is 1530/1520mm and towards cross ways it is 360-345mm. The spindle speed range is 45-1800 rotations per minute and the spindle step is 17 rotations per minute.

...more

Vertical CNC Milling machine

Cost effectiveness, functionality and durability are what you get from the WM series CNC vertical milling machine. The rigid structure of the equipment enhances the stability of the machine making it able to handle heavy vibrations and forces associated with milling. The triple axis feeding system is best for all types of vertical machining. The feed rate affects the evenness of the finished work. To avoid parochial marks from developing, the machine can be adjusted to higher feed rates thus reducing the roughness of the finished work. This equipment has the cutting feed rate from one m/min up to ten thousand meters per minute. The automatic control of the machine is one of the best innovations that have been introduced in the vertical CNC machine. It allows for automatic calibration of the machine to perform the required job. The design can be easily developed on the control system, which is user friendly while achieving good functionality. The digital control system also allows for storage of data and another design can be programmed as the machine continues with the previous one. The spindle motor has a power of up to 7.5 Kw making it very effective for machining any type of material. This motor is able to deliver up to 39.4 Nm torque which increases its ability to machine even more harder surfaces. The spindle can achieve a speed rate of up to 8000 rpm hence more production capabilities and better returns. Main Features:- High rigidity and high stability in CNC Milling Machine structure High precision three-axis feeding system High speed precision spindle Fast and reliable tool changing mechanism Cooling system High property electric control system The cooling system is vital in CNC milling and the equipment come with a fully functional cooling accessory. It eliminates heat from the work piece, which could lead to unwanted damages. The working lamp and the alarm lamp are also handy accessories for a CNC vertical milling machine. The spindle-blowing device ensures that no accumulation of chips on the spindle, which could lead to a poorly, machined surface. Another important accessory is the chips elimination system that operates continuously, preventing a buildup of cut material, which could interfere with the machine operation. Other important accessories can be supplied separately depending on the considerations of the user. The temperature control system gives early signal when temperatures are building up to higher than usual levels. It is very important in safety of the operator and preventing damage to the equipment. The door protection system is also a safety installation protecting the user from flying chips during operation. For users requiring a different type of gear head, the equipment can be supplied with another gear head as per their needs. Yash machine tool offers readily available spare parts for all their equipments. This is in line with the company’s efforts to provide the best customer service to their clients. The company also offers technical support concerning usage and maintenance of their machines. Equipment from Yash machine tools is cost effective, while offering the best functionality and optimal performance.

...more

Vertical Bandsaw Machine

A vertical band saw is used to cut curves and complicated shapes while the horizontal saw cannot cut curves because it applies gravity only.In horizontal band saw machines, it is the blade that moves to cut the material but in vertical band saw machines the work piece is the one that is moved across the stationery band.Vertical band saws are used in homes and small shops while horizontal band saws are used in big industries.

...more

Vertical Band Saw Machine

Horizontal band saw is used to cut large pieces of metal while vertical band saw can only cut small pieces. BH4228Horizontal band saw can cut the hardest metals but a vertical band saw can only cut pliable soft metals. The horizontal saws use a lot of power to cut hard metals while vertical saws only use less power. A vertical band saw is used to cut curves and complicated shapes while the horizontal saw cannot cut curves because it applies gravity only.

...more

vertical band saw

Vertical band saw is also known as the contour saw because the blade is kept stationery and the work piece is moved periodically across it. This type of a band saw is usually found at home and local shops. They are small in size and require less power. It is used to cut pliable metal using its circular endless blade for complicated cuts. Vertical band saws have an inbuilt blade welder for repairing broken blades or allow the blade to be purposely cut in order to do interior cutting. It also has a blower for blade cooling and to blow away the chips from the work area.

...more

used tool room machinery

In a nutshell, tool room can be defined as machinery room. But in a broad sense, it used for the machineries from the basic mechanical to the most advanced electronic and hydraulic machineries used in various industries for metal working and wood working. Tool room machines are used for shaping, milling, slotting and grinding function of metals and woods. Tool room machines are evaluated from ancient time and existing in the most useful form nowadays in factories and workshops to turn out the bulk work simultaneous. India is a leading source in manufacturing of tool room machines from years to meet the needs of local and international market requirements. Mechanical tool room machines are transformed now in high end electronic and hydraulic mechanism to extract good output in shorter time. There are various types of tool room machines used in industries like grinding machine, milling machine, shaping machine, bandsaw machine, hacksaw machine and slotting machine for different industrial requirements.

...more

Universal Milling Machine

Universal milling machine from Yash is known for its accuracy in milling and tensile guideways. It is easy to operate as the overall instrument structure is compact. Apart from general operation, this equipment is compatible for boring, slotting, drilling, cutting racks, gears and reamers with the support of additional cutting tool. We have two different models of universal type and two models of Universal knee type equipment. Qualities:- Ractangular table guideways with high stability. The spindle is made of alloy steel and uses precision angular contract bearings for powerfull cutting force combined with high precision. High precision; high strength Hardened and ground table surface Model No XW6136 : This tool is very compact in size and it is designed with rectangular dimension of table guideways. This particular feature provides the device excellent stability while performing strong grinding operations. The table size is 1320X360mm and the T-slot width is 14mm and distance is 95mm. The spindle axis to table distance is 0-400mm and the distance between ram to spindle axis id 175mm. We have provided ISO50 spindle taper. This model can work efficiently with 4KW powered motor which is also cost effective when it comes to power consumption. The overall equipment weight is 2300kg that makes it stay quiet efficiently for long term usage. Model No-X6436 : It is available with 1320X320mm of table size and T-slot number is 4 and width and distance of T-slot is 14mm and 95mm respectively. The distance from the spindle axis to table surface and from spindle axis to ram surface is 0-400mm and 175 mm respectively this distance decides the depth of milling. The spindle speed range is 58-1800 rotations per minute and it works with 4KW motor power. Special Qualities It has been provided with all the basic features like other types of milling machines It is a compatible device to handle different work materials The table can be moved in different directions that supports for flexible operation The T-slots are designed to support for fast performance as well as to hold the work materials at the appropriate positions The spindle in each model plays the key role in grinding and we have provided durable spindles driven by electric power motor.

...more

Turret Milling Machine

Yash Machine has exclusively designed WM Series Turret Milling Machine for carrying out vertical milling operations and suitable for small to medium machining jobs. We are one of the leading workshop machines manufacturers in India and we offer high performing equipments suitable for variety of engineering, sheet metal and automobile industries. We are very particular about selecting the base parts which should be made from higher quality materials. Above all the specialty of our turret mill is that the spindle is made of chrome molybdenum alloy which stays quiet effective for precise cutting operations. Turret Milling Machine Qualities:- All major turret milling machine components are made from high grade stress relived cast iron. The column and kenee slideways are of rectangular cross-section to provide a wide contact area and high rigidity. Slideway construction comprises an anti-friction material coating bearing on high frequency hardened surface for high machining precision and longer life. The spindle is made of chrome molybdenum alloy and uses precision angular contract bearings for powerfull cutting force combined with high precision. Turret Milling Machine – Main Features:- It is characterized by compact configuration, high flexibility, and Small floor space occupation. The milling cutter has a 90 degree of left/right swing and 45 degree of forward/backward swing. not only can the ram move forward and backward, but it can also rotate 360 degree on top of the column to dramatically increase the machining range. The tool body uses high-grade cast iron treated with artificial aging. The column and table (model no. >XA6325) use rectangle guideway that has large contacting surface and high-rigidity. The plastic-coated guide way treated with high frequency treatment, offers good machining precision and maintains long Life. The spindle made of chrome and molybdenum alloy uses precision angular bearing, with quenching and tempering treatment, which guarantees strong cutting force and high precision. The nut is made of high-grade phosphor bronze, which has excellent characteristics of wear resistance. Turret Mill Models We offer WM series Turret Milling Machine in four different sizes. They are; Notable for compact tool structure Flexible to make 90 degree milling cutter movement towards left and right and 45 degree cutter movement towards upward and downward direction. The mill is also designed to make 360 degree rotation which gives it extraordinary machining performance. All the basic parts including the nuts are made of superior grade phosphor bronze that has wear resistance property. Model No-WM 02 TM/2- X6323(2#) : This compact model mill comes with 230X1067 mm of table size and the table can bear 250kg of work material load. The spindle can travel 610/350/380mm of X/Y/Z axis. We provide optional head structures for all the four models which includes belt driven head, vertical steel head and variable speed head suitable from which consumers can select as per the productivity requirement. The spindle speed range differs in accordance with the kind of head stock selected. Model No-Wm02 TM/3-X6325(3#) : This model is provided with 254X1270X(1370) mm of table size and it can bear 300kg of load including equipment weight and work material weight. The spindle can move 780(880)/395/380mm of X/Y/Z axis travel respectively. The spindle feed rate is 0.04,0.08,0.15 of rotations per minute. The ram travel is 510mm and the ram rotation angle is 360 degree. Model No WM 02TM/4-XA6325 This model can bear up to 300 kg of load and the table size is similar to that of model non X6325(3#). The spindle can travel 780(880)/395/380 mm towards X/Y/Z axis respectively. The spindle feed rate is also similar to that of the above mill model. Model No-Wm 02 TM/5-XB6325(5#) : It has the same table size like that of model X6325 and XA 6325. The load bearing capacity is 350kg. When compared to other models this turret machine has spindle axis travel is 760(860)/420/380mm towards X/Y/Z axis. Spindle feed rate is the same in all the four models. We offer certain standard accessories such as draw bar, electric cabinet and the tool box with important tools. We also provide optional accessories which can be selected based on the productivity requirement in the industries. We have the following optional accessories like milling quick change collects, auto-feed device, oil-collection tray, machine vice, chip-guard, etc.

...more

Tube Notcher

The art of creating seats or groove forms on pipes requires professional experience. It is mainly preferred for inserting one piece of tube into another for which it becomes important to form an angle on the end of the pipe to produce the desired cut so that it can be fitted easily into another. However, these can be done flexibly with the assistance of pipe notching tool. This is small equipment that reduced limitations in cutting when compared to conventional types of saws. It provides higher operational aspects with incomparable tooling performance. Maintenance aspects are limited in this apparatus. Yash Machine Tools provides different models of tube notchers which bear varying capacities of creating cuts on pipes. It can be applied for notching varieties of hoses including the ones made of stainless steel, aluminium, titanium, brass, etc. In addition to the basic function, this device is also applicable making indentations in works including manufacturing of bicycle components, joining of different tubes, making of stainless steel hand railings, stair parts, nautical equipments, manufacturing of pipelines for industrial plants, etc.

...more

Trunk Folding Machine

We provide Trunk folding machine that is manually operated and manufactured with high skill, to deliver accurate bends on various sheet metals. The firm base of construction creates stability during bending, thus getting very precise angles during bending. The trunk folding machines are available with different specifications as per standard.

...more

tool room lathe

Banking on the strong domain expertise, we offer technically updated the array of Tool Room Lathe Machine, that is strong in nature and are functionally advanced.We offer them in varied standard configurations and can be easily installed in the required area. Our entire product range is corrosion resistant in nature and is delivered in well-defined time.

...more

Tool Grinder

Grinding is a delicate process among the different types of machining operations. This operation helps to obtaining finishing to the work material. Tool grinders are special grinding equipments that are specially designed to give finishing to different types of tools which are applied for cutting. This device stays very effective for performing complicated grinding. Yash Machine provides 7 different types this instrument with different machining capabilities. These are meant for finishing cutting instruments made of hard materials.

...more

TC SERIES PLANNING MACHINE

Innovation and great workmanship have been achieved in the production of this equipment. A planner device works based on the linear motion that is created between the cutting tool and the work piece. It is equivalent to that of lathe and shaping machine but can be applied to carryout machining on larger sized work materials. Here the table is moved backward and forward to do the tooling and helps in generating precise flat surfaces. It can also be used to obtain slots and brings smooth finish in just one movement. However, there will not be any degradation in quality of performance and precision. It is one of the useful equipments which work effectively for metal industries. Buy our TC series planning machine and experience more productivity with one time investment. Features of the TC Planning Machine Table size of 4000 * 1120 mm for the BX2012A model means that considerably large work pieces will be easily planned to perfection. A table load capacity of 8000 kgs allows the machine to easily handle the weight of the work piece. The table supports the work piece as it moves while being planned. The top side of the table has an accurate finish to ensure proper positioning of the work piece. It is also equipped with T slots for easier holding of the work piece while planning is going on. The column is heavily constructed to take up huge forces on it during operation. The machine is equipped with a cross rail that is adjustable thus allowing different heights of work pieces to be machined. This part is constructed with absolute accuracy because the tool follows the cross rails path in the cross feed operation. The table travel length is 4150 – 530 mm hence, a bigger work piece can be machined. The double housing system is more effective in planning of a variety of parts due to the ability to use multiple tools heads, or one can use individual tool heads depending on the type of work required. The incorporation of a lubricant pumping system means that excessive heat buildup is easily managed and the tool damage is minimal. Spindle power motor is rated at 45kw thus able to deliver more torque for best planning. The motor and the gearing system are designed to deliver maximum power during operation. This equipment is important in industry for construction and maintenance or large and flat metallic surfaces where the ordinary grinder is unsuitable. The TC planning machine is best for removal of bigger volume of material such as slots making, and will effectively work where the floor mill is not available. The machine is able to deliver high accuracy in removal of material due to incorporation of the automatic control panel giving a greater degree of accuracy. This equipment can handle work pieces of up to 4m x 1.2 m x 1 m in size and effectively plane to the required specifications. This makes it the ideal equipment for manufacturing of equipment bases and machining of flat beds, which serve as frameworks heavy machinery. Machining of identical but numerous parts can also be handled using the TC planner machine. The planner machine from Yash machine tools is manufactured with the highest level of workmanship and quality cast iron base for maximum absorption of forces during operation thus reducing the repair requirements. The company also offers great support and spares for their equipment therefore no need to worry about after sales service. This eventually leads to reduced frequency of repair and maintenance and better functionality of the equipment.

...more

Steel rolling machine

Yash Machine Tools provides plate rolling machines, which are perfect companion for sheet metal industries. These are available in different models with exclusive specifications developed to meet different industrial workshop requirements. These equipments are also designed to meet the concerned load of work materials. Machine structure is undoubtedly strong that withstands bending operations when higher work material load is fed. The components are made of heavy duty fabricated steel, the fabrication supports for longer performance and durability without much need for maintenance and also to withstand strain at time of overloads. These are hand operated, yet featured with excellent controlling options for obtaining precision in machining.

...more

spm milling machine

Yash Machine Tools offers the best quality SPM & Heavy machines. The imported SPM & Heavy Machines including vertical turning lathe, horizontal milling boring and vertical machining center are designed for optimum performance as per the international standards. The machines are set for high precision vertical lathe machining or horizontal milling with best strength and reliability. The industrial machining including lathe and milling is most economical. The components are sturdy and made from high quality metal sheets and materials for long durability. The SPMHeavy Machine is available at Yash Machine Tools in various models with varying capacities. Machine’s auto execution is quite vibration free and noise free for smooth handling and multi-tasking features. Workshop tools are of ample varieties and those that are meant for special purpose machining are considered significant to handle exclusive machining of work piece materials. Yash Machine Tools provide SPM and Heavy Machining components suitable for specific industries. We provide completely imported range of special purpose and heavy machines. These machines available with us are chosen for the design and performance. All the equipments are made in accordance with international standards of machine design. Special Purpose machines are designed and deliv

...more

Slant Bed CNC Lathe

Slant Bed Lathe with CNC provision available at Yash Machine Tools in WM Series as well in DMTG slant bed CNC lathe is an exclusive imported lathe designed for accuracy in machining and to stay compatible for higher production requisites in Industries. This equipment is strongly built and it is an ideal option for long lasting machining needs. The imported slant bed design allows flexibility in moving or tilting the bed upwards. The force of gravity that is created during the motion helps to stabilize slant bed motion. This feature also enhances precise machining output. The work area available in this instrument provides convenient angle for loading the work material and for easily machining. Qualities:- The new CL and DL Series of CNC slant bed lathes have rigid cast-iron structure hardend (50-52HRc) and ground to guarantee high precision and stability. Machine beds are made of heat stabilized cast-iron. A wide range of configurations are available with spindles from ASA 5” to ASA 15” , power up to 30 KW and turning length up to 3000mm. A wide range of options and accessories are available to customize the device for specific applications.

Swing Over Bed : 400 mm

...more

Sheet Rolling Machine

Plate rolling machines, which are perfect companion for sheet metal industries. These are available in different models with exclusive specifications developed to meet different industrial workshop requirements. These equipments are also designed to meet the concerned load of work materials. Machine structure is undoubtedly strong that withstands bending operations when higher work material load is fed. The components are made of heavy duty fabricated steel, the fabrication supports for longer performance and durability without much need for maintenance and also to withstand strain at time of overloads. These are hand operated, yet featured with excellent controlling options for obtaining precision in machining.

...more

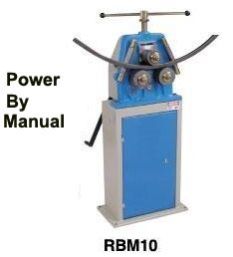

section rolling machine

We provide manually operated section rolling machine, which is an ideal device for fabrication workshops. This device is available in different models with different capacities equipped for bending. Consumers can choose the suitable model based on pipe diameter and bending. It is a friendly device and stays very supportive for workshops, technical institutions, etc. When it comes to industrial usage, Section roller is an excellent companion to support longer run productivity requirements. Find our more versions of section rollers from Yash Machine Tools as we have designed each model with specific capacity and mode of bending. Pricing is undoubtedly lesser than other types of bending tools. Rolling metal work materials is one of the toughest applications in industries. Our section roller is featured with strong top and bottom rolls and it is made of higher grade cast iron housing. It can withstand heavy duty production work. It is can be adjusted manually with the help of manual screw adjustment provided at the top roller. This equipment is quick in performance and stays very efficient for long run applications for decades. It helps to achieve sectional configuration on metal work pieces and this is considered to be one of the efficient methods of bending. It stays very helpful in the creation of precise products. Find out more information about this equipment by visiting our website. Special Cast frame Shafts are hardened with special steel material Rollers are special steel material hardened and grounded Gears milled with full material Optional rollers for choise

...more

Screw Tap Grinder

Tap grinding had not been a possible machining process in earlier days, as the work material has to be fed into different sorts of grinding machines to obtain the final form of tap grinding. Tap grinders or screw tap grinding device is a recently created and most innovative form of grinder especially created for tap grinding purpose. Yash Machine Tools presents 7 different models which have been designed with industry supportive grinding capacities. It is one of the recent developments in grinding mechanism One of the most attractive features of our screw tap machines is the flexibility in all terms like size of the machine, operation aspects, machining performance, device set-up in the workshop premises, and so on. There are many benefits which can be listed out to highlight the performance of this equipment such as, Specially equipped tooling options which can be chosen based on the industrial requirement. Available tooling options are front cutting lip, front cutting face, spiral flute tap cutting face, flat flute’s front cutting lip and face. Provides quick change over time. Reduces down lead time. One machine holds multiple grinding capacities therefore no need to shift the work material to different grinding tools for tapping operation.

...more

Screw Blade Grinder

Yash Machine tools presents tool blade grinder, a compact yet a legendry tool that helps for creating metal components like saw blades. Grinding metal work piece becomes perfect only if the metal is converted into precise shape as expected. Screw blade grinders are exceptional in mechanism as they can sharpen metal products at both ront and back angles providing edges with sharp end. Our grinders designed to create metal bodies in the desired shape and dimension and to grind the surfaces of the screws. Our grinding equipment made for machining screw propellers are meant for high speed production demand. It is the best machining tool for metal industry that produces intricate machining parts. It is highly preferred in metal and mechanical industry, automobile and aircraft making, etc. This is a perfect supportive component for making sharp ends of screws and saws. There are some catchy and attractive benefits it buying screw blade grinding equipments available at Yash Machine Tools they are, Designed to possess considerable power to perform grinding application. Can easily be sent for shipment as it is relatively compact than bigger size conventional grinding equipments. Requires lesser man power. Suitable for high speed production requisites. Constructed from high and durable quality metal components. Works with motor power yet consumes moderate power consumption. Requires between 220V/380V to run. Unique in design, performance yet cost effective. Durable, sturdy construction and suitable for long term and continuous production requirements.

...moreBe first to Rate

Rate ThisOpening Hours