Special High Temperature Resistant Elements

Many filtration conditions are with feed slurry temp. of upto 60-70 Degree Cent. & working pressure upto 4-5 Kg./cm2. But there are such requirements where filtration take place with higher temp. then 70 degree cent. Now, if you apply higher temperature beyond 70 degree cent., the normal PP Filter Elements will not work. PP material will soften gradually at a higher temp. Under long timefiltration condition, this may results in bending of PP filter elements, developing crakes or breakage of the elements. In such conditions, standard PP material does not fulfill the requirement and result in failure of filter elements. “Yotana” has developed such filter elements and moulding process by adding special additives and ICM moulding process where by you can go upto 85-95 degree cent. Temperature. We have already supplied our high temperature resistant filter elements in higher temperature filtration process & are proud to say they are working without any problem since many years, thereby reducing replacement cost, production & maintenance cost.

...more

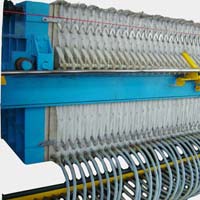

polypropylene filter press

Available in diverse sizes & types, the Polypropylene Filter Press, which we offer, are used for many Filtration conditions in diverse industries like: Dyes, Dyestuff, Chemicals, Minerals, Pharmaceuticals, Starch, Ceramic, Pollution Control & many more. Preserving and recycling water is imperative for us now. Presently these Polypropylene Filter Presses are also recommended for clarification of solutions as well as waste water effluent treatment & sludge dewatering process. By using the Polypropylene Filter Press, which we offer, in the above process the total operation of sludge bed drying is eliminated thereby reducing the large space of sludge bed eliminate the problems of overflow of the beds. Because of its simplicity and flexibility, our Polypropylene Filter Press has been widely applied in clarification and dewatering applications. Why Our Polypropylene Filter Press? Low power consumptionDurable designCost-efficientSimple to use Delivery Time : 4 weeks

...more

Multi Group Automatic Plate Shifting

Auto Plate Shifting mechanism to shift all the Filter Plates in different groups in different bunch operated through extra side Hydraulic Cylinders located on the side supports i.e. M.S. Flats of Filter Press simultaneously one after the other along with the opening of the Filter Press. The Filter Plates linked with the Moving Body by a specially designed lever & link design for equidistance opening of the Filter Plates during cake Discharge. The PLC is designed to operate the shifting device immediately after the filter press opening (moving & body is in fully open position).

...more

Membrane Filter Press Plates

We offer Membrane Filter Press Plates, which have a chamber below the drainage surface that can be inflated. The common method used is water pressure, which is generated by pumping into the squeeze cavity to inflate the face of the plate against the filter cake. The Membrane Filter Press Plates, which we offer, is sold under the brand name of Yotana. These Membrane Filter Press Plates are used to reduce the cake moisture content & shorten the filtration cycle time. Mix pack membrane are the most common configuration (one recessed plate then one membrane plate alternate in the press plate pack). We make available the Membrane Filter Press Plates, which are used for usually operating at a feed pressure of up to 7 bar and squeeze pressure up to 15 bar. These Membrane Filter Press Plates can be designed for higher feed & squeeze pressure. Replaceable membranes can easily changeable. EPDM thermoplastic and other compounds are used for specific conditions. Details Payment Terms : T/TPackaging Details : Necessary Packing done in wooden boxesDelivery Time : 3 - 4 Weeks

...more

Membrane Filter Press

The initial operation of a membrane filter press is identical to that of its recessed chamber counterpart. However once the filtration cycle is complete and final filtration pressure is achieved the feed into the filter press is stopped. At this point the plates within the Filter Press can be inflated using either air or hydraulic pressure to exert a mechanical force on the filter cake retained in the chamber. The effect of the squeeze is to physically compress the filter cake and force out additional moisture held within the cake giving a drier end result. Membrane filter plates are used to Reduce filter cake moisture content Reduce filtration cycle time Improve cake washing This style of filter plate can be installed as A full plate pack Alternately in conjunction with recessed companion plates as a more economical option. Because of its simplicity and flexibility, the chamber Filter Press has been widely applied in clarification and dewatering applications. Membrane Filter Press technology is gaining increased acceptance because it reduces subsequent processing or disposal costs for filter cake. In many applications the membrane Filter Press significantly reduces residual moisture content, making this technology attractive for new plants and for upgrading existing facilities. In both cases the careful selection of plate and membrane materials is essential to the successful performance of the process. Membrane Filter Press Plates have a chamber below the drainage surface that can be inflated. The common method used is water pressure, which is generated by pumping into the squeeze cavity to inflate the face of the plate against the filter cake. Membrane Plates are used to reduce the cake moisture content & shorten the filtration cycle time. Mix Pack Membrane are the most common configuration (one recessed plate then one membrane plate alternate in the press plate pack). Membrane Plates usually operate at a feed pressure of up to 7 bar and squeeze pressure up to 15 bar. Special plates can be designed for higher feed & squeeze pressure. Replaceable membranes can easily changeable. EPDM thermoplastic and other compounds are used for specific conditions. Plate filling problems are minimized and use of a rubber Membrane enables “empty-chamber” operation without damaging the plate, resulting a considerable reduction in incidents of plate failure. Even if the chamber is not completely filled, the filter cake is squeezed by the inflating filter lever and therefore perfectly dewatered. During the initial phase of the filtration cycle, so-called “fill and filtration” the process is similar to the chamber Filter Press. After reaching a predefined pressure, usually around 3 - 7 bar, depending on the sludge characteristics, sludge feeding is stopped & the rubber membranes inflated, using either water or air as squeeze medium. The cake is hereby compressed and dewatered further. Then the squeeze medium is relieved & the cake discharged.

...more

Membrane Filter Plates

The initial operation of a membrane filter press is identical to that of its recessed chamber counterpart. However once the filtration cycle is complete and final filtration pressure is achieved the feed into the filter press is stopped. At this point the plates within the Filter Press can be inflated using either air or hydraulic pressure to exert a mechanical force on the filter cake retained in the chamber. The effect of the squeeze is to physically compress the filter cake and force out additional moisture held within the cake giving a drier end result.

...more

Mechanical Plate Shifting

Automatic Individual Mechanical Chain Driven Plate Shifting Mechanism by the help of specially developed shifting Dogs.

...more

Inlet and Outlet Valves

From Gujarat, India, we present a wide gamut of Inlet and Outlet Valves to the length and breadth of the country and overseas as well. We are credible Manufacturer, Exporter & Supplier of Inlet and Outlet Valves that are made from the top-notch quality material and widely demanded. Offered at the best market prices, our Inlet and Outlet Valves stand tall on expectations.

...more

Individual Plate Transport System

The Plate Shifting Device shifts individual plates (One after the other) immediately after the filter press opens (i.e. after the moving end body is retracted ) operated by hydro motor with necessary chain and sprocket design. Necessary controls for speed and pressure are incorporated in the hydraulic power pack unit.

...more

I-Beam Type Over Hanging

INTRODUCTING NIRMAL POLY PLAST INDUSTRIES OVERHANGING I –BEAM TYPE FILTER PRESS OF 1500mm X 1500mm SIZE HAVING 90 CHAMBERS ADVANTAGES BY USING YO – TANA’S OVERHANGING DUAL I – BEAM TYPE FILTER PRESS Huge Sludge (Solid) Handling capacity upto 10 M.T./Single Batch (Dry). Easy Handling. Less Wear & Tear. Easy Filter Cloth Washing as No Side Bar. Easy Cake Dropping & Scrapping. Less Maintenance. As Plates are Overhanging Type no Handles Sliding on The Side Bars Hence. No Wear & Tear of Side Bars Thereby Increase Strength as Main Supports Are I – Beams on The Top. Easy Access to the Centre Hole For Cleaning. Large Treated Water Handling capacity upto 20 Lacks Liers / Day. FEATURES Overhead Dual I-Beam in Place of Side Bars (M.S.Flats). Smooth Movement as all Plates Including Moving Body are Sliding with Rollers on I-Beam. Large Sludge Handling Capacity Upto Plates Shifting Mechanisam can be Provided. Hydraulic Power Pack System. P.L.C. Based Control Panel for Fully Automatic Operations Like: Auto opening / closing, Auto Feed Pump on /off. Auto Boom Door Drip Collection Tray, Auto Plate Shifting, Auto Conveyor etc…

...more

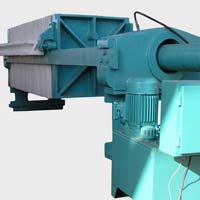

Hydraulic Filter Press

Having years of experience in this field, we present an optimum quality range of Hydraulic Filter Press from Delhi, India. We are backed by a team of professionals who make use of top class material for manufacturing the product. As a result, best in line product is delivered to the end user. Further, we keep all the requisite arrangements for quick and safe shipments.

...more

Conveyor Belt

Accessible in different specifications, our another variety is Conveyor Belt. The company has a team of quality auditors who keep their eyes on the quality of Conveyor Belts during various production stages. Buyers can consider our name for urgent and bulk requirements. Rely on us for timely deliveries. We are renowned Manufacturer, Exporter & Supplier of Conveyor Belt sited in India.

...more

Conventional Filter Press

Filter presses are extensively used to separate solids from liquids in a wide range of applications. The liquid solid mixture is pumped into the filter press, which is made up of a number of recessed filter plates forming chambers. The plates are supported in a fabricated steel frame and is held closed by a force exerted from a hydraulic ram mounted in the frame work at the end of the machine. Each filter plate is covered by a filter cloth that retains the solid particles, but allowing the liquid to pass through and exit through the ports in the filter plate. The particles retained gradually build up on the surface of the filter media and after a period of time eventually form a solid cake. As the cake forms the pressure within the filter press the pressure rises as the filtrate has to pass through the already partially formed cake to exit the chamber. It becomes increasingly more difficult to continue pumping as the press is unable to accept more solids. At this point the feed pump is stroking infrequently and the filtrate flow from the filter press has considerably reduced or completely stopped. At this point or at a pre determined filtration time or pressure being achieved the cycle is terminated and the fully formed filter cake is discharged.

...more

Door Drip Tray

Automatic Door type Drip Collection Tray (Hydraulically operated) for Drip Collection during capillary action & peripheral filtrate collection during cake discharge. The Drip tray is control by a special logic from the Panel having special operations & pauses for different operation like : Filter Cloth washing, peripheral filtrate drain and Drip collection.

...more

Automatic Plate Shifting Machine

Made from the rust proof material, our Automatic Plate Shifting Machines are widely appreciated for their low power consumption and long operational life. By keeping records of the leading market demands, we offer Automatic Plate Shifting Machines in different technical specifications for the convenience of the buyers. We are recognized Manufacturer, Exporter & Supplier of Automatic Plate Shifting Machine and known for our fair price policies.

...more

Automatic Plate Shifting

Auto plate Shifting mechanism to shift all the Filter Plates simultaneously at a time along in a single stroke with the opening of the Filter Press. The Filter Plates linked with the Moving Body by a specially designed lever & link design for equidistance opening of the Filter Plates during cake Discharge.

...more

Automatic Inlet-Outlet Valves

Pneumatically Actuator operated Ball valves with FRL Unit(Filter, Regulator, Lubricator) with necessary Solenoid valves for Slurry Inlet, Cake Airing, Cake Washing, close filtrate Outlet, Air Purging (core blowing inlet / outlet] all operated in a programmed sequence as required during the operation logically controlled by PLC.

...more

Automatic Filter Cloth Washing System

We are Manufacturer, Exporter as well as Supplier of Automatic Filter Cloth Washing System sited in Gujarat, India. These systems are assembled from the quality-tested components, thus optimum quality is assured. Thanks to our huge production facility that makes us capable to render them in different specifications, defined by the clients. Rely on us for timely deliveries.

...more

Automatic Filter Cloth Washer

Fully Automatic Membrane Filter Press with Automatic Filter Cloth Washer.

...more

Auto Plate Lifting-Shifting

Automatic Plate Lifting device (cam operated) for cake discharge. It is driven by Hydraulically operated motor (Hydro motor). The cams are located on both the side of the Filter Press side bars. It is provided to shake the Filter Plates which helps the cake to drop from the Filter Cloth.

...more

Filter Presses

inlet valves

From Gujarat, India, we present a wide gamut of Inlet and Outlet Valves to the length and breadth of the country and overseas as well. We are credible Manufacturer, Exporter & Supplier of Inlet and Outlet Valves that are made from the top-notch quality material and widely demanded. Offered at the best market prices, our Inlet and Outlet Valves stand tall on expectations.

...moreBe first to Rate

Rate ThisOpening Hours