Die Punches

Get Price Quote

We are the manufacturer of this products. this product is design high-efficiency product . We are working from last 15 years.

HSS PUNCH

30 - 850 Per Piece

20 Piece (MOQ)

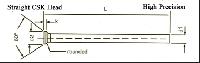

Our company is consisted of a group of loyal employees which include researchers & technicians. By implementing the advanced method of production & total quality management, we produce the following products: Ejector pins, Stepped Ejector pins, Core pins, Piercing punches, Blade ejectors, Sleeve ejectors, Bush pillar sets, Jig bushings, Sprue bushings & Die-sets, and other precision ground components. In order to satisfy the demands of different customers, our products have over 10 categories, & almost 10 thousands sizes are available ready stock in each category. So far, the quality of our products is guided by the concept of "Pursuing and Achieving the International Standard", the administration is motivated by the idea of "Factualism & Innovation". Our vision is to be a leading provider of standard Tool Room products to the plastic/sheet metal/ die-casting Engg. Industries. We are in process of becoming ISO 9001:2000 certified company and striving to continuously increase the quality of the products by targeting on the market & monitoring the management of the organization. We make punches in HSS as per IS4296 DA type. The head is softened or annealed. The Punches other than DA type is to be specifically mentioned at the time of giving order. Length: Standard lengths are 50, 70, 80 & 100 mm DI : the Values of diameter d1 are recommended in steps of 0.05 mm upto 0.95 dia and in steps of 0.1 mm from 1.0 to 6.4 mm dia and in steps of 0.5 mm from 6.5 to 16 mm diameter. Note: Non Standard items are manufactured as per Customer's Satisfaction.

Best Deals from Punches

round punches

Get Price Quote

We are highly acclaimed for our superior quality product range which includes precision punches and piercing punches etc. These bonafide precision punches and piercing punches are exceedingly durable and result oriented. Our all products are as per the Indian standards and parameters. We have accepted the contemporary challenges of this competitive market and proved ourselves as the best exporter, wholesaler and suppliers. The high demands of precision punches have placed us on the top over the chart. We are glad to say that we are the one and only precision piercing punches exporter based in India. We offer a wide variety of precision piercing punches that include: Our Precision Piercing Punches (Manufactured as per standards specified by IS:4296-1967) These precision punches are manufactured from suitably selected high speed steel (HSS) and special alloy steel (WPS). Punches are heat treated and triple tempered under strict quality control. The punches are precision ground to close tolerances and surface finish is maintained between 0.3 to 0.4 µm. Head hardness of punch - 45 Rc ± 5 Shank hardness - 60±2 Rc (for WPS material) Shank hardness - 62±2 Rc (for H.S.S. Material) Standard sizes are regularly manufactured, though special sizes step punches, step ejector pins and shapes can also be manufactured as per customer's requirements. Precision Piercing Punches Length : Other Lengths are 35,40,50,60,70,80 & 90 mm d1 : The values of diameter d1 are recommended in steps of 0.05 mm upto 0.95 mm dia and in steps of 0.1mm from 1.0 to 6.4mm dia and in steps of 0.5mm from 6.5 to 16 mm diameter. Finish: Hardened, Tempered & Precision plunge ground and Lapped Surface Finish: 0.3-0.4 µm Hardness: Shank WPS 62+-20 Rockwell C , HSS 64+-20 Rockwell C, Head 45 +- 50Rockwell C Designation: Round piercing punches should be designed by the type, material, the normal size, the length and standard