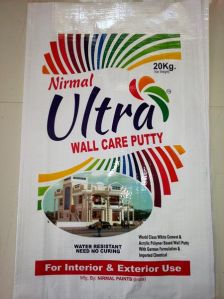

Water Resistant Wall Putty

We are a renowned for manufacturing and exporting of the best quality Water Resistant Wall Putty. Water Resistant Wall Putty that we offer is extracted using the advanced techniques and technologies. Our Water Resistant Wall Putty is water resistant and needs no curing. Our White Cement & Acrylic Polymer Based Water Resistant Wall Putty comes with German formulation and imported chemical. Water Resistant Wall Putty that we offer is used for interior and exterior use. We are capable of taking up bulk orders of Water Resistant Wall Putty. Clients can avail Water Resistant Wall Putty from us at affordable rates. Specifications Weight : 20 KGM.R.P. : Rs. 560 Production Capacity Putty : 300-500 MT monthly

...more

Silica Powder

We are manufacturing and exporting excellent quality Silica Powder for the customers all across the globe. Our natural Silica Powder has purity of more than 99.7%. Silica Powder that we provide comes in a very snow white color and the whiteness in A grade silica is more than 96%. Silica Powder, offered by us, is available in 100 mesh, 200 mesh, 300 mesh, 10 microns D-97. The average particle size in micronized Silica Powder is below 5 microns. Silica Powder has minimum SiO2 98.5% in mining area. The Chemical Composition Of Our Silica Powder Is As Under Quartz Silica Powder : We have Quartz Silica powder with maximum purity Of 99.75% SiO2. The Mesh Size is available from 100 mesh to 300 mesh. The brightness in 1st grade quartz powder is 97%. The minimum SiO2% in our mining area is 98.5% , it means, we have 98.5% purity in our lower grade which it best available in India. Quartz Silica Powder is suitable for all ceramic applications, ceramic colors, ceramic frits, paint industries and other applications.Quartz Silica Sand : We also well-acclaimed Manufacturer and Exporter Quartz Silica Sand of same purity 99.75% in 1st grade and 98.5% in last grade. This sand is super white in color and available in 0.1 mm to 3.0 mm also in mesh size like 8/12, 16/30, 24/60, 30/80, 50/150, etc. Other than these regular mesh sizes, we offer Quartz Silica Sand as per customer’s requirement in case of minimum bulk orders 100 M.T.Micro Silica Powder : We are also manufacturing and exporting premium Micro Silica powder with average particle size of 3 to 4 microns and topcut 10 to 12 microns which is above 1000 mesh. Specification Of Silica Powder SiO2 99.72%MgCO3 - 0.01%Fe2O3 - 0.04%CaO - 0.03%Al2O3 - 0.05%LOI - 0.09%Specific Gravity - 2.55Whiteness-95% to 98%Color - Snow White Production Capacity Silica : 500 MT monthly

...more

Quartz Powder

Our Quartz Powder has excellent qualities, and therefore serves various applications in foundries and filtration systems. Quartz Powder that we offer may be transparent to translucent and has a vitreous luster. Hence, Quartz Powder, we provide, is used in glassmaking and ceramics industry. Quartz is hard, chemically inert and has a high melting point, attributable to the strength of the bonds between the atoms. Quartz’s strength, silicon dioxide contribution and non-reactive properties make it an indispensable ingredient in the production of thousands of everyday products. For industrial and manufacturing applications, deposits of Quartz yielding products of at least 95% SiO2 are preferred. Industrial Applications Of Quartz Glassmaking : Quartz sand is the primary component of all types of standard and specialty glass. It provides the essential SiO2 component of glass formulation and its chemical purity is the primary determinant of color, clarity and strength.Metal Casting : Quartz is an essential part of the ferrous and non-ferrous foundry industry. Metal parts ranging from engine blocks to sink faucets are cast in a sand and clay mold to produce the external shape, and a resin bonded core that creates the desired internal shape.Metallurgical : Quartz plays a critical role in the production of a wide variety of ferrous and non-ferrous metals. In metal production, Quartz sand operates as a flux to lower the melting point and viscosity of the slags to make them more reactive and efficient. Quartz Lump is used either alone or in conjunction with lime to achieve the desired base/acid ratio required for purification. Base metals can be further refined and modified with other ingredients to achieve specific properties such as high strength, corrosion resistance or electrical conductivity. Ferroalloys are essential to specialty steel production, and industrial sand is used by the steel and foundry industries for de-oxidation and grain refinement.Chemical Production : Silicon-based chemicals are the foundation of thousands of everyday applications ranging from food processing to soap and dye production. In this case, SiO2 is reduced to silicon metal by coke in an arc furnace, to produce the Si precursor of other chemical processes. Quartz is the main component in chemicals such as sodium Quartzite, silicon tetrachloride and silicon gels. These chemicals are used in products like household and industrial cleaners, to manufacture fiber optics and to remove impurities from cooking oil and brewed beverages.Building Products : Quartz is the primary structural component in a wide variety of building and construction products. Whole grain Quartz is put to use in flooring compounds, mortars, specialty cements, stucco, roofing shingles, skid resistant surfaces and asphalt mixtures to provide packing density and flexural strength without adversely affecting the chemical properties of the binding system.Paint and Coatings : Paint formulators select micron-sized industrial sands to improve the appearance and durability of architectural and industrial paint and coatings. High purity Quartz contributes to critical performance properties such as brightness and reflectance, color consistency and oil absorption.Ceramics & Refractories : Ground Quartz is an essential component of glaze and body formulations of all types of ceramic products, including tableware, sanitary ware and floor and wall tile. In the ceramic body, Quartz is the skeletal structure upon which clays and flux components attach. Quartz products are also used as the primary aggregate in both shape and monolithic type refractories to provide high temperature resistance to acidic attack in industrial furnaces.Oil and Gas Recovery : Known commonly as proppant, or “frac sand,” industrial sand is pumped down holes in deep well applications to prop open rock fissures and increase the flow rate of natural gas or oil. In this specialized application round, whole grain deposits are used to maximize permeability and prevent formation cuttings from entering the well bore. Production Capacity Quartz : 600 MT monthly

...more

Mica Powder

We can provide Mica powder in various forms and is obtained by grinding/breaking mica scrap, which is a slow, costly and extremely complicated process, because of the scrap being tough and having a plate like structure. We take meticulous care and precaution that there is no deterioration in natural brilliance, color and properties of our Mica Powder. Our factories for processing Mica Powder are fully equipped with latest pulverisers. Mica Powder, we provide, is used in welding electrodes, cables and wires, foundry works, texture paints, acoustical plaster, ceiling tiles, plastics, etc. Production Capacity Mica powder : 600 MT monthly

...more

Feldspar Lumps

Chemically, Feldspar Lumps that we offer are silicates of aluminum containing sodium, potassium, iron, calcium, or barium or combinations of these elements. Our Feldspar Lumps are primarily used in industrial applications for their alumina and alkali content. The term feldspar encompasses a whole range of materials. Most of the products, we use on a daily basis, are made with Feldspar Lumps, for instance, glass for drinking, glass for protection, fiberglass for insulation, the floor tiles and shower basins in our bathrooms, and the tableware from which we eat. Industrial Applications Of Feldspar Lumps Glass : Feldspar is an important ingredient in the manufacture of glass and an important raw material as well, because it acts as a fluxing agent, reducing the melting temperature of quartz and helping to control the viscosity of glass. The alkali content in feldspar acts as flux, lowering the glass batch melting temperature, and thus reduces the production cost.Ceramics : In the manufacture of ceramics, feldspar is the second most important ingredient after clay. Feldspar does not have a strict melting point, since it melts gradually over a range of temperatures. This greatly facilitates the melting of quartz and clays and, through appropriate mixing, allows modulations of this important step of ceramic making. Feldspar is used as fluxing agents to form a glassy phase at low temperatures and as a source of alkalies and alumina in glazes. This improves strength, toughness and durability of the ceramic body, and cement the crystalline phase of other ingredients, softening, melting and wetting other batch constituents.Fillers : Feldspars also are used as fillers and extenders in applications such as paints, plastics and rubber. Beneficial properties of feldspars include good dispersability, high chemical inertness, stable pH, high resistance to abrasion, low viscosity at high filler loading, interesting refractive index and resistance to frosting. The products used in such applications are generally fine-milled grades. Enamel frits and glazes : Feldspar assists the enamel composition, assuring the absence of defects and the neatness of the end product: e.g. enamel frits, ceramic glazes, ceramic tile glazes, sanitaryware, tableware, electrical porcelain and giftware. And many other end-uses : Paint, mild abrasives, urethane, welding electrodes (production of steel), latex foam, the welding of rod coating, and road aggregate. In the flooring sector, feldspar is the main constituent in the body composition. It is used as a flux, lowering the vitrifying temperature of a ceramic body during firing and forming a glassy phase. Surface Tension pulls the remaining solid particles together, giving a densification of the ceramic body. With rising temperatures, alkalis become more active and first dissolve the clay particles, and then the free silica. In tableware, feldspar gives a good fusibility for a product without defects. In sanitaryware, the use of feldspar within vitreous ceramic bodies is used to facilitate the optimization process. Production Capacity Feldspar : 500 MT monthly

...more

China Clay Lumps

We are regarded as one of the topmost China Clay Manufacturer and Exporter from Ajmer, Rajasthan. We present superior quality China Clay Lumps that are used in large number of industries such as paper, rubber, plastic, paint etc. Known for their physical and chemical properties, our China Clay Lumps are highly demanded in the market. In addition to this, we provide China Clay Lumps in different quantities and packing as per requirements of the customers. We also ensure delivery of China Clay Lumps stipulated timeframe. Additionally, we provide China Clay Lumps at the most affordable prices. Applications Extensively used for making crockery and decorative itemsVitrified TilesVitrified Tiles / Glaze Tiles Properties Easily MoldableFine TextureGet white color when put on fire100% natural Production Capacity China Clay : 800-1000 MT per month

...more

Feldspar

Be first to Rate

Rate This