Premix Ramming Mass

6,200 Per Ton

56 Ton (MOQ)

Our premix acidic ramming mass is prepared using the best raw material, latest technology and under strict supervision of trained staff. We prepare material in both quartz and quartzite. We prepare the material for induction furnaces having capacity from 0.5 - 40 tons. Our premix ramming mass is worldwide recognized for its quality and patching life. We assure our clients of maximum heat resistance of our material

Acidic Ramming Mass

2,800 - 3,500 Per Metric Ton

20 Metric Ton (MOQ)

Best Deals from Ramming Mass

Premix Ramming Mass

Get Price Quote

We are known for providing only flawless range of products as we store the entire lot under safe environment in our spacious warehouse. Moreover, the lot is regularly checked by our experts. Buyers can order our products in bulk, as we maintain year around availability. In addition, we have reliable transportation system to make timely delivery.

Acidic Ramming Mass

Get Price Quote

We “Shree Ratan Minerals” are proud to introduce ourselves as one of the leading suppliers/manufacturers of industrial products such as: Acidic Silica Ramming Mass (pre-mix or post-mix), Quartz Grains & Powder, Mica, Feldspar and other related minerals. Made from premium quality material each of our delivered products has defect-free finish and widely used in various industries.

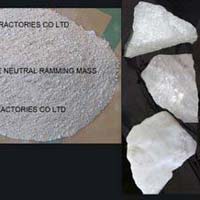

Silica Ramming Mass

Get Price Quote

A white coloured substance, the Silica Ramming Mass is in high demand. As one of the most trusted manufacturer of this product, we also supply and export it to many of our clients from all parts of the world. The rates at which we offer this product are extremely nominal and market leading as well. Our happy clients are our foremost concern and we ensure satisfaction in each deal. Features : It is Good resistance to temperature change,Low cost in furnace lining. Short heating and sintering time through dry preparation Of masses. The price is very attractive compared to others. Silica ramming mass can safely be used up to an operating temperature of 1600°C it expands very little so it is superior to both alumina and magnesia to resist thermal shocks. Secondly its cost is very low in comparison to alumina and magnesia. Silica can be used for melting copper and copper alloys including cupronickels with change in amount of binding agent additions. For brasses melting silica lining is the “ideal “choice Granulometric composition of commercial silica ramming mass. Size Percentage : 4mm to 1mm 33% 1mm to 0.20mm 30% 0.20mm to0.06mm 17% 0.06mm & below 20%

Acidic Ramming Mass

Get Price Quote

We have carved a niche as the most reliable Silica Ramming Mass manufacturer and are also listed among the most eminent suppliers of the same. Our company has also become the first and foremost choice of many of the leading industries as we provide superior Acidic Ramming Mass that is well suited for there applications.

Premix Ramming Mass

Get Price Quote

We are offering premix ramming mass . we offer high quality premix ramming mass to our clients. Used extensively in high capacity furnaces, the premix ramming mass has excellent composition and properties. The premix ramming mass is available to clients at market leading prices. We always ensure minimum wastage while mixing the premix ramming mass. benefits proper mixing of binder leading to optimum mixtureless wastage, as mixing is done by machines.use of only imported boric acid gives best resultsconsistent and longer lining and patching lifeone less item in inventory

Ramming Mass

Get Price Quote

Our Ramming Mass is available in its premixed form as well. We mix well all the contents including the binder to form an optimum mixture. We always ensure minimum wastage while mixing. We are one of the overriding premixed ramming mass manufactures from India. We bring superior quality premixed ramming mass which is available in premixed versions also. We are a distinguished leader in promoting premixed use in big capacity induction furnaces. Our all the grades are available in premixed versions also. Premixed gives the following benefits to the user: Proper mixing of binder leading to optimum mixture. Less wastage, as mixing is done by machines. Only use imported Boric Acid is used to give best results. Consistent and longer lining and patching life. One less item in inventory. We offer all sorts of premixed ramming mass at the most affordable price.

Acidic Ramming Mass

Get Price Quote

We have carved a niche as the most reliable silica ramming mass manufacturer and are also listed among the most eminent suppliers of the same. Our company has also become the first and foremost choice of many of the leading industries as we provide superior acidic ramming mass that is well suited for respective applications. Besides this, customers are also facilitated with delivery of the quartz ramming mass within the stipulated time frame. Acidic/Silica Ramming Mass is basically made from Quartz only but comprises of 150 meshes to 4-16 mm grain. This is used in Induction Furness as Iron, out of the ground, melts at around 1510 degrees C and Steel often melts at around 1370 degrees C, but Quartz melting point is 1650 degree C. This powder form of Quartz is available in different percentage calculated on the presence of 4-16 mm grain. This depends on the size and liner’s choice. This mixture is then mixed with Boric Acid and then dumped as lining in Furness. A good Ramming Mass can sustain for 20 heats approx.

Acidic Ramming Mass

1,800 Per Metric Ton

Quartz Ramming Mass

Get Price Quote

Quartz Ramming Mass, Fine Mesh Powder

Packed Ramming Mass

Get Price Quote

Packed Ramming Mass, Premixed Ramming Mass, Quartz Dust, Quartz Grains

Ramming Mass

Get Price Quote

We are the main supplier of this product.

Ramming Mass

Get Price Quote

Feldspar Grains, Quartz Grit

Acidic Ramming Mass

Get Price Quote

Ramming Mass

Get Price Quote

Acidic Ramming Mass

Get Price Quote

Calcite, Dolomite, industrial mineral powder, Feldspar Lump, Hemetite Powder

Silica Ramming Mass

Get Price Quote

Acidic Ramming Mass

Get Price Quote